High bay LED lighting has really changed the way of illuminating commercial and industrial settings, with better energy conservation, higher brightness, and lower tariffs over time. Be it a large warehouse, a manufacturing plant, or a vast retail store, making the right choice for lighting is essential for maximizing productivity, conserving energy, and ensuring safety. At this point, we will go in-depth into the study while giving you a substantive understanding of high bay LED lighting, as we consider its primary benefits, key characteristics, and applications. By the time you’re through with this reading, you will be ready to make financial decisions concerning your interests in lighting upgrades necessary for defining your activities in the best way possible, and which will potentially decrease your operational costs.

Introduction to High Bay Lighting

High bay lighting is a form of indoor lighting specifically designed to be used in large spaces with high ceilings, varying from 20 to 45 feet in height. This provides intense light from wide angles that offer visibility for facilities such as warehouses, manufacturing centers, school gymnasiums, and super retail outlets. Minimizing shadows with its efficient, aimed lighting from long distance overhead, high bay lighting ensures safe and productive operation in bigger spaces. This type of illumination is tough-built for durability and energy efficiency, ideal for the industrial and commercial environment, where reliability and performance are very important.

What are High Bays?

High bay lights offer a specialized form of lighting suited for environments with high-ceiling applications, usually ranging from 15 feet and above. With fixtures designed to evenly illuminate a wide area, high bay lights are well-suited for industrial, commercial, and warehouse applications. Advanced optics are often used in the design to help ensure that there is no shadowing or glare while uniformly distributing light arrival over a high bay space. This classifies high bay lights we have been discussing among energy-efficient luminaires, long-lasting and dependable appliances for tough conditions. Conversely, these high bay lights are mandatory in settings where the best and most effective lighting is crucial for safety, efficiency, and productivity.

Benefits of LED High Bay Lights

LED high bay lights provide various benefits, contributing an excellent advantage in industrial and commercial applications. The reduction in energy usage is one of the main advantages. They often consume noticeably less power than any other traditional lighting modalities, such as fluorescent or sealed vapor lamp types, and hence represent a massive reduction in power costs. Given the extended life of LED, in some cases exceeding 50,000 working hours, the maintenance headache of maintaining and repeatedly replacing LED fittings vanishes altogether.

So, one of the major advantages of LED high bays seems to be a Giga-high brightness and good color rendering index to maximize visibility, thereby promoting the safety and productivity of the work area. Better still, because they emit virtually NO heat, it leads to a suffused environment, hence taking off air-conditioning requirements, another energy saver. Moreover, the LED high bay does not have poisonous substances like mercury, and the full product falls under the definition of recyclable. This, therefore, qualifies the LED high bay lighting fixture as the provision for the most durable, in terms of cost and sustainability, in a highly demanding environment.

Applications of High Bay Lighting

High bay luminary scales are specially designed for high ceiling spaces. The elevation positioning of these light fixtures is typically appraised at 20 feet above the floor. Their service has often advanced to larger industrial and commercial applications. For example, in warehouses, these lights expose the whole hall to lighting with high lumen output; that way, inventory control and all levels of safety are guaranteed. Local busy manufacturers produce the high bay discomfort lighting required for lighting one end of the workroom specifically, and allowing the other somewhere along a path or a specific assembly point for carrying whatever is on demand. In gymnasiums, as in sports complexes, there is a uniform spread of light over the more vast areas that can enhance the visibility of activities or events. Also used in hangars, retail stores, and exhibition buildings, for instance, applications for high bay lights are aimed at creating high-intensity functional spaces adapted to specific needs.

Types of High Bay Fixtures

The design, features, and application scope categorize high bay fixtures. The leading types can be all as follows:

LED High Bay Fixtures

These fixtures are relatively more efficient in energy utilization. Their bright light has a long-lasting effect. The rugged, evenly designed, reduced power costs are of high efficiency. They are tremendous for use in warehouses, manufacturing plants, and other high-ceiling spaces.

Fluorescent High Bay Fixtures

They use fluorescent tubes to feature slightly less energy-efficient, less bright illuminating solutions. Therefore, they are an affordable choice for moderate light needs on warehouse floors. In a certain sense, they do require more constant maintenance in light of LED options, though.

HID High Bay Fixtures

Although typically emitting high lumens, they usually have both the metal halide and high-pressure sodium lamps. While the energy efficiency is technically relatively low, a remarkable lumen result can be achieved dynamically. LEDs and, therefore, spirit grumbling have to be accepted as cybersecurity shortcomings.

Induction High Bay Fixtures

Induction high bay fixtures are fixtures that create light from an electromagnetic field. They are durable and have excellent longevity. They can be found in applications where very demanding and rugged conditions exist, such as in an industrial establishment.

An important line of demarcation in the selection of the right type of high bay fixture is the amount of space available in that building, the lighting requirements, focus on energy efficiency, and the maintenance services that can be contracted.

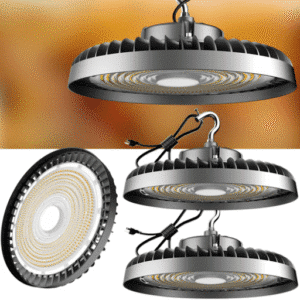

UFO High Bay Lights

High Bay UFO Lights are a new, futuristic option tailored to industrial and commercial usage. This compact circular model ensures a wide-reaching, consistently distributed light, making it perfect for high-ceiling areas, usually from 15 to 50 feet. These lights are powered by smart LED technology for better energy output, longer life spans (often above 50,000 hours), and fewer maintenance requirements when compared to traditional lighting systems.

UFO High Bay Lights come with a very strong and sturdy construction that equals IP65 or higher to resist dust, moisture, and harsh environmental conditions. They are also suitable with dimming systems and motion sensors, which allow them to be further energy-saving and further customization for lighting options. Features that one should consider in UFO High Bay Lights include lumens per watt (efficacy), color temperature, and beam angle, in accordance with the lighting requirements of a given facility. Warehouses, gymnasiums, factories, or any other big area that requires reliable and uniform lighting are ideal locations to install these luminaries.

Linear High Bay Lights

Linear High Bay lights are specialized for the evenly distributed, energy-efficient lighting of vast indoor spaces such as warehousing, retail stores, and manufacturing sites. The aspect of these fixtures that distinguishes them from the traditional UFO high bays is their rectangular style for a wider light spread, which makes them a good fit for aisles and elongated spaces. When considering Linear High Bay Lights, essential things to be regarded include power in watts, lumen output, and fixture dimensions to ensure that its compatibility will serve the necessary application and mounting range. Dimming options, motion sensors, and the flexibility of various mounting arrangements are also engineered into the design of the linear high spots to bring in more energy savings and clearer functionality. Given their top-end performance, the linear high bays make an ultimate, durable solution for commercial and industrial applications.

Low Bay vs. High Bay Lights

Low bay and high bay industrial lights are completely different kinds of fittings that are designed with respect to ceiling heights and applications. Low bay lights are designed to have a uniform, wide lighting distribution up to 20 ft high from floor to ceiling without causing any excessive glare. They are quite suitable for retail spaces, some small warehouses, and pretty maisonettes. They diffuser or reflector-based light distribution, which is quite uniform in itself.

High bay lights are different, purposefully constructed for ceilings that can range from 20 to 45 ft or higher. They give direct, powerful lighting over large spaces, i.e., factories and gymnasiums, etc. High bay lights are equipped with more optical lenses and higher lumens, helping to have light beaming at exponent angles without any compromise in brightness or clarity.

Low beam and high beam fixtures are essentially two separate types of devices with very different variables considered when designed. Low-bay lights have an average style, with lower requirements in terms of wattage, whereas high-bay lights display robustness in construction, heat-management systems, and compatibility with modern technologies like motion sensing and dimming control. The determination of which one to choose rests with the height of the facility, required light intensity, and needs according to the application areas.

Choosing the Right LED High Bay Light

Choose the best LED High Bay Light based on these important criteria:

- Ceiling Height: Specifically, an LED High Bay Light is perfect for ceiling heights above 20 feet. Choose the right beam angle light that lends uniform light across the space. For a higher ceiling, the narrower beam angles will give a better quality of light as compared to wider angles that suit best on lower heights.

- Lumens Required: Differentiate the brightness levels required for the size and use of the space. For instance, spare areas might vary in lumens with those intended for work where clarity is the Indian’s criterion.

- Color Temperature: You are to choose the requisite color temperament for the environment. Cooler temperatures (5000K-6500K) are task-oriented but more suitable for creating a comfortable atmosphere, while warmer tones (3000K-4000K) can only wish to make things more inviting.

- Energy Efficiency: Look for luminaires with a high efficacy rating, i.e., lumens per watt, to maximize energy savings without sacrificing performance.

- Durability and Features: Choose lights with heavy-duty construction, good heat dissipation, and extra features such as dimming controls or motion sensors, depending on light requirements in the application. Make sure the certification of its longevity and safety is properly in place.

Consideration of these might help weigh your selection for an LED High Bay Light, comfortably falling in line with your particular needs.

Factors to Consider

When evaluating LED High Bay Lights alternatives, the primary concerns concerning wattage, lumens, light output, beam angle, and color temperature should address the usual questions about performance, efficiency, and suitability:

Wattage & Brightness

The light output (measured in lumens) should confirm you have the right illuminance for your facility and that your energy-saving wattage selection should be consistent with this. Higher ceilings may need higher lumens to facilitate proper light coverage.

Beam Angle

Put a priority on appropriate beam angles, given the ceiling height and ultimately determined by the amount of space requiring illumination. The narrow ones focus more light on specific areas, while the wide distribution of light by them over vast spaces generally gives more even light.

Color Temperature

Choosing a color temperature according to your application should be recommended, with cooler temperatures (5000K–6500K) best for performance-oriented living and working spaces and warmer tones (3000K–4000K) for areas in need of comfort or mood lighting.

Lifespan and Warranty

The efficiency of the product, as measured in operating hours, along with warranty coverage, must be carefully analyzed. The greater the lifespan, the lower the maintenance cost, and, at last, the more reliable the product is.

Certifications and Compliance

Also, make sure that certifications from DesignationLightingConsortium (DLC), Underwriters Laboratories (UL), and CE are certified or validated to meet regulatory and industry standards.

Such deliberation over these factors would help you choose the right high bay according to your functional needs and the cost of operations in your environment.

Lumen Output and Light Distribution

Selecting an LED High Bay Light requires a strong grasp of lumen output and light distribution if optimal lighting performance is the aim. When it comes to measuring illuminance output, lumen output may be defined in lumens (lm), which is the total of visible light there is when emitted by the fixture. Working with an example, calculating the required lumen output means calculating the illuminance (lux measurements) that your space fully satisfies concerning size, height, and deployment, since industrial and commercial areas typically need greater lux-to-lumen. For instance, a warehouse normally needs 300-500 lux, whereas manufacturing environments may ask for 500-750 lux for detailed tasks.

A uniform light distribution helps guarantee even illuminance without dark patches or glare. The high-bay lights preferably have various beam angles like 60°, 90°, and 120°. A narrower beam angle concentrates the light over smaller specific points, whereas wide angles are suited for wider spaces with lower ceilings. To achieve further even light distribution, consider fittings such as prismatic lenses or reflectors for more effective light distribution. The right lumen calculation with custom beam angle ensures intensified energy savings, as well as perfectly fulfilling the light’s specific requirements on your site.

Color Temperature: 4000K vs. 5000K

While assessing the color temperatures ranging between 4000 and 5000K from a design perspective, it would be pertinent to consider whether the space is posed toward function or appearance. 4000K lighting emits a neutral white tone and is usually recommended for places that need a balance between warmth and clarity, such as offices, retail, or classrooms. In its employment, it would create a delicate, natural-like illumination without bothering human eyes.

The decision between 4000K and 5000K should be based on the activity in the room, desired atmosphere setting, and existing interior design. Usually, 4000K is the preferred option in spaces requiring a professional but warm atmosphere, while 5000K is considered optimal in work areas where functionality and visibility are the most important criteria.

Installation and Maintenance of High Bay Fixtures

In the high bay fixtures, installation follows the correct judgment of the appropriate type of fixture for height and intended application. All electrical components must be compatible with wiring systems in compliance with the local code. Secure the fixture to the ceiling with appropriate mounting hardware, such as hooks, chains, and brackets, to prevent movement or damage during installation.

For maintenance, fixtures should be cleaned periodically to remove dust and debris that could obstruct light output. Regularly inspect lenses, drivers, and wiring elements for signs of wear and damage. Promptly replace any faulty components to maintain efficient performance and safety. Periodic checks must be scheduled for verification of the lighting quality and the absence of disturbances.

Installation Tips for High Bay Lights

Determining the right mounting height and the installation of the luminaires

High bay lights are typically made for ceilings ranging from 15 to 40 feet. Be sure to install them according to the manufacturer’s guidelines for production placement and spacing to ensure an even light level.

Select the Appropriate Mounting Accessories

Depending on the fixture’s characteristics, ensure the type of compatible suspension chains, pendant, or U-hook hardware. Whatever the equipment mounted, the mounting accessory must have a weight rating that is compatible with the installation.

Prepare Electrical Wiring System

Make certain that the power rating is within the range permitted for the high bay lights being installed. The wiring must be of suitable size, while ensuring that the voltage in the system matches the rated voltage of the lighting fixtures. Next, ensure that to switch off the electrical power to avoid accidents while fixing the wiring.

Fixtures Installed and Tightened

Follow the manufacturer’s instructions to securely attach arms and luminaires to the mounting hardware. Use tools to tighten all connections, and also check for stability after a full assembly to prevent dislodgement.

Test and Calibrate the Fixtures

Restore the power and start testing the devices. The light should be tested for beam angles, brightness, and spread. Then, adjust all positions to eradicate dark or partially lit areas as necessary.

Provide for Future Maintenance

Fix the fixtures so that they can be removed easily for periodic maintenance. Keep a written record of the model, the date of installation, and performance indicators to aid future inspections or replacements.

Maintaining Your LED High Bay Lighting

Maintaining LED high bay lighting is crucial for the optimum performance of the fixture and its long life. Here are some crisp points taken from expert sources:

Keep It Clean

Dust or link build-up can obstruct the light entering the room and also affect the thermal management. Always clean the fixtures occasionally with a dry, soft, lint-free cloth or compressed air. Disconnect the power before undertaking cleaning activities to avoid electrocution or accidental damage.

Adjustments For Any Poor Performance

If you are coming across flickering lights, LEDs dimming down, or irregular lighting, you might need to focus on some other failures, such as the driver, LEDs, or poor connections. All of these can result in damage if not addressed promptly.

Checking the Heat Draining

LED high bay lights must have an active method of heat expulsion for high-performance operations. Check the heat sinks for reasons that they might be blocked or overheating, and please make sure the fitting locations have enough air.

Investigating Electrical Components

Make sure the wiring, connections, and power supply are still there and that they operate effectively. Loosely connected wiring or worn-out cables may mismanage systems or create safety hazards.

Plan Preventive Maintenance

Create a maintenance plan recommended by the manufacturer. Regular checks on the system from time to time, provided they are accurately backed up with repair and replacement information, should guarantee the longevity of the new lighting system.

It can improve efficiency, lower company operational costs, and ensure safety in your work facility.

Common Issues and Troubleshooting

| Issue | Cause | Solution |

|---|---|---|

| Shine and Flicker | Loose wires, incompatible fan dimmer switches, and loitering bulbs | Help or replace parts after checking loose wires; replace the dimmer or bulb |

| Used up Bulbs | Burnt fuse, electrical or light buildup | When forced, replace fuses. Watch for two breakers fallen from the circuit breaker box, tracking as far as setting up the circuit. Have light bulbs in the proper spot as well as placed properly |

| Unleveled Lighting | Incongruous bulb wattages, lens grime, or improperly-laid-out fixtures | Remove and respace the fixtures, apply the considered choice between lighting shifts, and make the lenses undergo a second purification treatment |

| Overheated Lights | Wrong bulbs for the project, disguising the ventilation | Wind down the wattage on inappropriate bulbs, and ensure that the fixtures have proper ventilation |

| Short Life of the Bulb | Power supply problems, bad standard light bulbs, and improper handling | Protect against electricity fluctuation with a surge protector, use standard light bulbs, and handle them during installation with care |

If you tackle such problems punctually and look for specifically intended solutions, you will end up with a lighting system that is reliable for sure and in many ways.

Advanced Features in High Bay Lighting

High-bay lighting frameworks have evolved into precision tools that now boast innovative features enhancing function, efficiency, and user convenience. The major features include:

- Energy Efficiency: Track lighting equipment, like many high bay lights, is now manufactured to incorporate remote LED technology to greatly reduce energy consumption while also maintaining an excellent lumen.

- Smart Controls: With an array of motion sensing, daylight sensing, and wireless remote control options, these systems can be programmed to offer a good field of light while conserving energy.

- Dimming Capability: With controls to dim these light fixtures, the lights can illuminate the work, as they should, making this thing most ideal for working under surface finishes or detailed tasks.

- Further Toughness: The present-day high-bay devices are built with strong materials so that they are able to resist the tough environments of factories and warehouses.

- Heat Management: Improved measures of heat dissipation will extend the service life of the lighting system and ensure consistent results.

These features ensure that high-bay lighting systems can be trusted as reliable, cost-effective, adaptable solutions for large spaces.

Motion Sensors in High Bay Fixtures

Advanced energy-saving capabilities are provided by the presence of motion sensors on high bay fixtures, by operate lights when needed. These sensors allow for automatically activating or dimming the lighting in relation to occupancy levels. Common types of motion sensors are passive infrared (PIR) sensors, microwave sensors, and ultrasonic sensors; each enhances detection range and sensitivity for different uses. PIR sensors are commonly used indoors, as heated objects make them operate; hence, better open spaces are more suited for microwave sensors due to the latter’s ability to reach across surfaces.

Motion sensors decrease electricity usage and reduce wear and tear on the lighting system. They also increase the service cycle of fixtures. With unbeatable sensor technology, dimming controls, and other interconnected devices, they are now integrated perfectly, providing a completely bespoke lighting experience. Among the impressive attributes on offer, motion sensors certainly play a central role in attaining efficiency and sustainability in an industrial and commercial paradise.

Smart Lighting Solutions for Warehouses

Smart warehouse solutions will allow one to optimize energy efficiency, thus reducing operational costs and enhancing overall functionality. Given motion sensors, automated dimming systems, and perhaps IoT connectivity, you can exercise adaptable lighting, which can either be on or off, contingent on real-time activity and occupancy. This will ensure the best result of where and when lighting is most needed while helping minimize energy loss, and aligns with sustainable objectives.

Energy Efficiency and Cost Savings

In a warehouse, opting for an intelligent lighting system will certainly help in saving energy and cutting costs. By replacing traditional lighting systems with LED models, which consume less power than their ancestors, warehouses will cut down energy consumption by up to 75%. Motion sensors and daylight harvest capabilities are some advanced operational technologies put into these advanced systems that allow the light to operate just when needed; such compounds can be further used to dim or increase light output per natural lighting conditions. By connecting to an IoT, companies take control to another level as well, as it provides real-time monitoring, predictive support, and adaptive control. Systems can now have significantly lowered operational costs due to decreased energy use, decreased maintenance charges due to the longer lifespan of LEDs; justification now exists for a substantial long-term operational advantage to move forward with alternative environmental practices.

Reference Sources

“Moving Targets and Moving Markets in Commercial Lighting”

“Planning Guidelines for Enhancing Placemaking with Tall Buildings”

“Optimum Design of Retail and Wholesale Building for Minimum Energy Consumption and Total Cost”

Frequently Asked Questions (FAQs)

What is a high bay LED light fixture, and how does the fixture differ from traditional lighting options?

High bay lightings are basically used in high-ceiling environments, especially for industrial activities such as in warehouses, factory floors, or gymnasiums. When it comes to differences with traditional lighting systems like metal halide or high-pressure sodium, high bay LED fixtures consume less energy and thereby save, start much faster, last far longer, necessitate fewer maintenance chores, and emit very steady light. Many of the high bay fixtures provide either 4000K or 5000K light and usually contain dimming and instant restart features not characteristic of traditional sources of light.

When should a warehouse owner choose a linear high bay led light or an all-in-one LED linear high bay for his / her warehouse lighting?

When you want to get wide and uniform lighting in aisles and racking in LED warehouse lighting and commercial/industrial environments, our choice will be LED linear high bay or LED linear high bay light. Linear high bay LED fixtures are especially suitable for warehouse lighting and industrial areas because their slender design ensures a uniform spread of light across the hall, which means shadowless bands with lighting levels designed most uninterrupted by continuous rows of light fixtures; they are especially good for spaces having high bay ceilings of 20′ or higher.

For high ceiling applications, would UFO LED high bay lights be better, or would UFO LED high bay light fixtures be better?

Round high bay lights focused on light concentration, and thus they are considered to be more user-friendly when it comes to installation due to their smaller size than traditional linear high ceiling fixtures. A UFO LED high bay will emit a high lumen output per watt, which is perfect for industrial and commercial ceiling space applications. Pick UFO fixtures for those largely open factory floors and high bay areas where a focused, high-output, low-glare approach is aimed.

How does an array of LED high bay fixture choices directly impact the overall energy savings of a commercial lighting project?

The LED high bay fixtures (LED UFO high bay and linear high bay LED style) can remarkably impact energy saving with higher efficacy in comparison to standard light sources. Commercial LED fixtures can cut lighting energy use by 50% or more by minimizing direct cooling loads, thus reducing overall cooling load, attractiveness, and maintenance costs. Proper installation, lighting selection, and planning give the best lighting, focusing on achieving equally targeted lumen output distribution and color temperature levels like 4000K or 5000K that go well with the work requirements.

Which kinds of high bays are the most common? Which are suited well for industrial settings?

Common high bay LED types comprise LED linear high bay, UFO LED high bay (round LED high/UFO light), and round high bay or round UFO high bay fixtures. For commercial and industrial spaces, opt for an LED linear high bay light for aisle-focused layouts and a UFO LED high bay for open-floor industrial areas. However, other factors such as the height of the mounting in feet, the distribution of the light source, and the possibility of low bay lighting alternatives in lower ceilings also play roles in this decision.

Can LED warehouse lighting and shop lights replace high- and low-pressure high-intensity discharge and traditional light sources in factories?

Yes, LED warehouse lighting and shop lights can, in fact, replace high-pressure or traditional light sources in factories or in commercial lighting applications. They produce a better color rendering, instant on, and temperature range-independent stable performance. By replacing traditional lighting with their LED counterparts, maintenance can be reduced and worker visibility improved, and design flexibility can be opened using LED bulbs and LED modules.

For a project like a store or commercial area, which is better to go for: the round high bay or a linear LED high bay?

Go in for a round high bay (LED round/UFO) for the required heavy lumen output focused into open retail spaces or commercial high ceiling spaces, whereas a linear LED high bay would serve the proper purpose for continuous rows of aisles or over workbenches. While making a choice, consider the lighting layout, the type of lights necessary for commercial work, and the desired uniformity. Pay close attention to ceiling height, shelving configuration, and focus on general lighting or task-specific lighting.