Get in touch with us

Leave a message

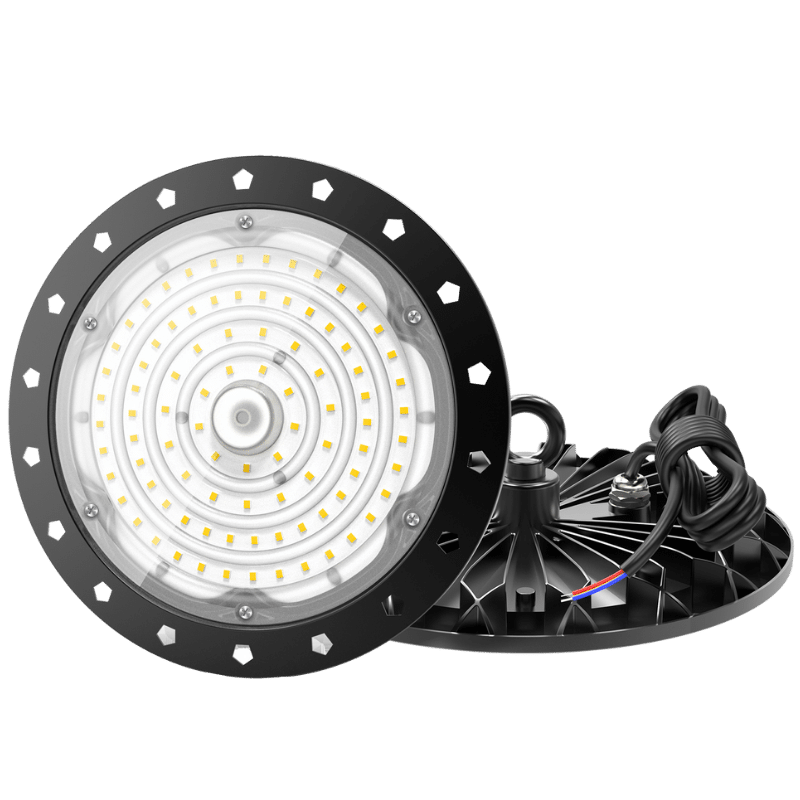

Our UFO High Bay is engineered to deliver powerful, consistent illumination for the most demanding environments, ensuring you can enhance workplace safety while drastically reducing energy consumption.

Our UFO High Bay Lights are built from the ground up for superior reliability and output. Featuring robust die-cast aluminum housings for optimal heat dissipation and premium LED drivers for stable, flicker-free light, they deliver powerful, uniform illumination with exceptional energy efficiency.

Our products are of high quality and will provide you with first-class results and meet all your needs.

Heavy-duty housing for impact protection; Vibration-resistant UFO High Bay Light construction; Optimized for 24/7 operation

High-performance optical systems (140 lm/W); UGR19 anti-glare technology; True color rendering (RA90)

Extended -40°C to 50°C operating range; Industry-leading 5-year warranty; TÜV-verified reliability

ISO 9001:2015 Certified Manufacturing

TÜV SÜD Performance Verified

IP66/IP68 Environmental Protection

International Safety Compliance (CE/UL)

These certifications collectively paint a picture of a high-quality, reliable, safe, and durable product designed for professional and demanding environments. They signify that our light has been rigorously tested and is manufactured under strict quality controls.

XD3-UFO LED Shop Light

ZS UFO High Bay Led Shop Light

XD3-UFO LED Shop Light

D8-UFO High Bay Light

We take pride in providing exceptional service and high-quality high bay light, and nothing makes us happier than hearing from our valued customers.

“Probapro UFO High Bay Lights withstood our automotive plant’s harsh conditions where others failed.”

Production Manager, German Manufacturing Plant

“72-hour delivery from their Czech warehouse kept our cold storage facility operational during critical expansion.”

Operations Director, Danish Food Processor

Stay informed with our latest articles, technical guides, and industry analysis designed to help you define a comprehensive lighting solution defined by quality, reliability, and unwavering performance.

Discover how Probapro’s commitment to quality can transform your space. Explore our products or talk to a specialist today.

Here, you will find answers to common inquiries regarding our processes, expertise, and the solutions we offer.

A: We ensure quality through a comprehensive, multi-stage Production Protocol. This end-to-end process includes Design Validation, rigorous Material Inspection, extreme Stress Testing, a 72-hour aging test for every unit, and final Photometric Calibration. This guarantees that every light meets our highest standards for performance and durability.

A: Durability is engineered from the start. Our designs undergo extensive Stress Testing, including thermal cycling, vibration tests to simulate industrial conditions, and IP65/67 water and dust ingress tests. We also use only high-grade materials, like die-cast aluminum and impact-resistant lenses, which are verified during our Material Inspection phase.

A: We believe superior products are built from superior components. Our Material Inspection stage mandates the use of components from industry-leading brands known for their performance and reliability. Every batch of LED chips and drivers is inspected to verify its specifications, ensuring consistent light quality and electrical stability.

A: Yes. Our Design Validation process allows for various configurations, including different beam angles (60°, 90°, 120°), mounting options, and dimming controls (0-10V, DALI). Furthermore, our Global Operations Network includes technical support teams who can use our certified IES files to help you create a lighting plan optimized for your facility.

A: Lead times are optimized through our Global Operations Network. By maintaining strategic inventory in regional warehouses across North America, Europe, and Asia-Pacific, we can often ship standard configurations immediately. For larger or custom orders, our efficient production line and stable supply chain ensure predictable and competitive lead times.

A: Our commitment continues long after the sale. Our Global Operations Network provides localized technical support for installation guidance and troubleshooting. Additionally, our Field Monitoring program allows us to collect performance data and customer feedback, which helps us provide better support and continuously improve our products.

A: Compatibility is a key part of our Design Validation and Stress Testing stages. Our drivers are designed to operate on a wide voltage range (e.g., 100-277V) and are tested for electrical stability, Power Factor (PF > 0.95), and low Total Harmonic Distortion (THD). We also conduct surge protection tests to ensure the lights can handle the power fluctuations common in industrial environments.

A: Sourcing directly from Probapro gives you complete transparency and confidence. It allows for better quality control, as we oversee the entire Production Protocol ourselves. It also facilitates clear, direct communication with our engineers for technical support and custom requirements, ensuring you get the exact lighting solution you need without any intermediaries.