Big box retailers have always struggled with lighting their large, open-floor spaces, and warehouses and gymnasiums haven’t been any easier. Wide-span, uniform illuminations calls for specialized light fixtures called high bay lights, which are a class apart in providing efficient lighting. Custom made for throwing light over a wide open area from a great height, high bay light fixtures are the only effective solution. But why exactly are high bay lights so essential, and in what ways do they improve energy efficiency and lighting functions in such complicated spaces? This article will cover the aims of high bay lights in order to explain their benefits, and cover the ways in which they improve safety, enhance productivity, and impact the ambiance of a large space. Don’t go away; in this article, I will explain the reasons why these fixtures mark such an important advancement in the industry of lighting solutions.

Understanding High Bays

Definition and Functionality of High Bay Lights

High bay lights are tailored lighting tools created to light up an area with a high ceiling, generally between 20 and 40 feet. The lighting fixtures are designed sturdily so that the light spread is balanced and light is transmitted efficiently so as to reduce shadowed areas. These types of lamps and lighting fixtures are used in warehouses, factories, gyms, and large retail stores. High bay lights specialize in offering efficient and powerful illumination for energy-concerned high-ceiling spaces.

LED high bay lights are widely used now, especially because of the high energy efficiency as well as the extended lifetime in comparison to metal halide or even fluorescent-based lighting, LED high bay lights are also ecological and efficient while lowering energy consumptions and maintenance. Furthermore, advanced functionalities like smart controls, motion sensors, and even dimming features can improve the modern high bay lights and can offer customized lighting while enhancing safety and increasing efficiency in large commercial and industrial spaces.

Differences Between High Bay and Low Bay Lights

Though both high bay and low bay lighting use the latest technology in LED lighting and can be energy conserving and adaptive, choosing the right lighting depends on the height of the ceiling and other parameters in that area to be able to fully illuminate the space and provide the needed functionality for the area.

Applications of High Bay Lights in Different Environments

High bay lights are common in specialty lighting where there is a need to light spaces with heights of 20 feet and above. They are especially useful in the setting of warehouses, gyms, as well as industrial and large retail stores due to their powerful illumination.

Warehouses and Industrial Facilities

In areas with expansive floor areas, high bay lights provide strong illumination that is uniformly distributed to aid in worker safety, especially in areas with heavy machinery or high shelves. Energy-efficient LED high bay lights are particularly preferred due to their reduced operational costs and enhanced durability.

Sports Facilities and Gyms

To sport gyms and indoor arenas, high bay lights are essential and specialized lighting is needed for high and even illumination over the playing surfaces. The color rendering customization of LED lights enhances the visibility for the players and spectators to an elegant level by providing clear visibility of the ongoing action.

Retail Stores and Supermarkets

High bay lights are used in large retail and supermarket stores because of the large LEDs and lighting coverage to provide bright illumination for the display of products for the sake of customers’ shopping. High bay lights are designed and crafted to reduce shadows and hot spots, which aids to increase the shopping pleasure of the store.

Aircraft Hangars

Because of the significantly large aircraft hangars and their high ceiling, aircraft hangars are one of the spaces that need high bay lighting. Their wide area and high ceilings need lighting whose brightness is consistent, as high bay lighting provides, ensuring the safety of operations and enabling precise maintenance even in very dim lighting.

Exhibition Halls and Convention Centers

These multipurpose venues need efficient lighting systems to adapt to various events, including trade shows and concerts. The high bay lighting systems combine dimming functions and temperature controls and provide flexibility needed for such morose environments.

Industry Trend: According to trends, we can see a growing concern for energy-efficient lighting especially LED high bay lights, as we witness their growing usage in industrial and commercial sectors. With the adoption of LED modern technology, the functionality of high bay lighting is improved, in addition, to facilitating sustainability’s objectives, which is the reason many operators are embracing the technology.

Types of High Bay Light Fixtures

Advantage and Features of LED High Bay Lights

The LED high bay lights bring a lot of added features and advantages to the table and stand out as the best choice for facilities with a sizeable area to illuminate. The LED high bay lights stand out in energy performance, needing barely a fraction of the power that metal halide or fluorescent high bay bay lights need. The LED high bay lights are more than efficient in maintenance, requiring significantly less check-ups and repairs, and their long-lasting lifespans assure that. And, of course, their LED high bay lights offer superior and brighter illuminations and an even light spread that strongly aids visibility which is vital for safety and heightened productivity in an industrial setup.

Recent statistics from ‘s search engine indicate that users are seeking LED high bay lights in an effort to meet energy and sustainability goals in an advanced manner. One of the frequently asked questions is, “Why are LED high bay lights good for industrial spaces?” Their relevance and adaptability answer that question. For warehouses, factories, and similarly designed high-ceiling spaces, the LED high bay lights stand out in terms of design and function. Not only do they perform optimally in extreme temperatures and vibrations, but they also maintain a consistent light output. In addition, the smart controls and dimming features integrated with these lights enable businesses to better manage and reduce their energy and carbon footprints, providing exceptional adaptability. This global LED high bay lights trend is largely due to the above-mentioned motivation and unparalleled innovation in performance and energy effectiveness.

Fluorescent vs. Metal Halide High Bay Lights

✓ Fluorescent High Bay Lights

- More energy-efficient

- Longer lifespan

- Lower operational costs

- Faster start-up and shut-down times

- Stable illumination

- Less heat emission

⚠ Metal Halide High Bay Lights

- High-intensity lighting

- Good for large commercial spaces

- Shorter lifespan

- Higher energy consumption

- Higher maintenance costs

- Requires warm-up time

Industry Shift: As the latest data shows, new business setups and refurbishment of existing facilities are moving away from metal halide lighting because of its inefficiencies to either fluorescent or modern LED lighting. What stands out is the usage of LED which outperforms both the fluorescent and metal halide in terms of energy savings, lifespan, and brightness control. Hence, even though fluorescent lighting still has a place, the adoption towards LEDs shows that the industry is moving towards more advanced and sustainable lighting systems.

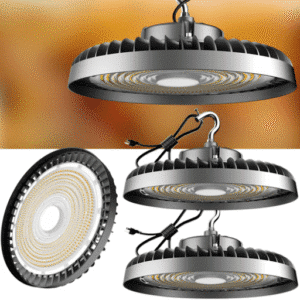

Round High Bay and UFO High Bay Choices

Round High Bay and UFO High Bay lights are now leading the pack for industrial and commercial lighting systems because of their ruggedness, efficiency, and multi-purpose nature. Round High Bay lights shine in providing blanket coverage while replacing outdated lighting in warehouses, factories, and big box stores, which requires lighting to be mounted high. Efficient heat dissipation allows for intense lighting, which is why UFO High Bay lights are preferred for high-intensity areas. Their compact design further adds to their appeal.

Choosing the Right High Bay Light

Users want to know which light is preferred for their needs as per the recent query data from ‘s search engine. Their needs are most affected by the lighting design, cost, and height of the ceiling.

UFO High Bay Lights

Recommended for areas with tall ceilings or those requiring bright pinpoint lighting. Superior optics and higher lumen output.

Round High Bay Lights

Perfect for light installations and upgrades. Require less effort while providing well-balanced and efficient lighting.

Both types boast integration with smart lighting controls that allow for additional energy savings and promote sustainability, but the ultimate decision lies in the needs of the application.

Energy Efficiency and Sustainability

How Might High Bay Lights Reduce Operational Costs

In regard to operational costs, High Bay lights are significant — especially when paired with contemporary LED technology. Compared to outdated lighting options, such as metal halide or fluorescent lighting, LED lights utilize significantly less energy, sometimes reducing energy consumption by more than 50%. These lights also feature an extended lifespan, which can be as long as 50,000 hours, further saving on maintenance and replacement costs. Energy efficiency is also improved with advanced optics and smart controls, which not only enhance light distribution but also provide features such as motion sensing and programmable dimming. This is further reinforced by “energy-efficient lighting” and “LED High Bay benefits” search queries, which have shown sustained growth, indicating businesses and industries are looking for ways to align sustainability with cost savings.

Impact on Energy Consumption and Sustainability

The use of energy-efficient lighting, especially LED High Bay lighting solutions, affects energy use and sustainability in a particular way. The use of LED systems is known to provide a 60-80% reduction in energy use when compared to the use of traditional lighting systems. Such a reduction in the demand for energy systems not only results in a decrease in the operational costs of such systems but also in a reduction in the system’s greenhouse gas emissions, aiding in the fight against climate change. In addition, consumer and business alike have consistently wanted to find the best value for their money as shown by the growing interest in energy-efficient lighting solutions, which is highlighted in the search trends of Eco-friendly Lighting. As the data suggests, industries are rapidly adopting innovative lighting solutions, which is crucial for energy conservation and for bolstering sustainability initiatives.

Comparative Analysis of High Bay Lighting Efficiency

High bay lighting options are known for having a significant difference when it comes to energy efficiency and performance in comparison with other options. With the aid of the new technology, the older methods, such as using fluorescent and metal halide lights, are not only less efficient but also have a lesser lifespan and higher operating costs. On the other hand, LED high bay lights are greatly efficient and, not only do they help save more with maintenance, but their lifespan is also greatly improved.

Market Trend: The most recent data further supports this trend, showcasing a surge in interest for “LED high bay lighting” and “energy-efficient industrial lighting” over the past year. This data highlights a growing awareness among businesses aiming to reduce operational costs while meeting sustainability benchmarks. These metrics suggest that companies are increasingly recognizing LEDs as a viable solution to enhance efficiency without compromising illumination quality.

A question arises as to why is led high bay lighting becoming the dominant choice in industrial settings. The answer is that is offers economically and environmentally balanced solutions to offer bright and uniform lighting at reduced energy costs. By integrating LEDs, industries not only adhere to energy laws but also actively participate in meeting sustainability targets, which is essentially contributing to a greener tomorrow.

Installation and Maintenance Considerations

Recommended Approach for Setting Up High Bay Fixtures

The high bay lighting fixtures need to be properly installed to ensure the device functioning well, is safe to use, and is durable. Here are some things to consider, as advised by the latest research and industry guidelines:

Evaluate the Space Needs

Look at the height and design of the area beforehand. High bay light fixtures are suitable for ceiling heights that are between 15 and 45 feet. Make sure that the fixtures are spaced well to cover the whole area in light without losing light in some areas or having an excess of light in some parts. For instance, in expansive areas, the light may be more effectively distributed if the fixtures are placed in a staggered manner.

Selecting the Appropriate Fixtures and Lumen Output

Different facilities need different levels of lighting. For industrial plants, warehouses, and sports stadiums, order fixtures that have the right lumen output for the intended use of the facility. Studies have shown that LED high bay energy-efficient lights are the most ideal as they offer very high light output and very low power draw.

Adhere to Manufacturer’s Instructions

Observe all instructions given by the manufacturer while installing the fixtures. This includes the mounting hardware, wiring, and recommended tools. An appropriate mounting system is necessary to avoid injuries, as well as to preserve the functionality of the system for a long time.

Controls and Sensors

Energy efficiency can be improved for high bay lighting by the installation of controls and sensors. Modern high bay lights can have motion sensors and dimming controls, and their installation can improve the energy efficiency of the lighting by adjusting the light to the occupancy or the available daylight.

Full System Test

Test the lighting system to assure proper placement, light intensity, and functionality. Test the lighting before full installation. Make sure you test the lighting system to check alignment, light levels, and functionality. This ensures any changes can be made prior to the complete installation.

Adherence to these lighting guidelines makes it easier for industries to capitalize on the high bay lights, and ensures safety, illumination, and energy efficiency in the working environment.

Maintenance Tips for Lighting Systems

In order to keep lighting systems functional, enduring, and effective, maintenance has to be done regularly. One effective way to deal with this is implementing regular checks to spot potential malfunctions, dimming, or flickering. Fixtures can get dust, and cleaning them using relevant materials is important in maintaining brightness. LEDs are an example of energy-efficient bulbs that should be used since they have a longer life and lower replacement rates. Ensure that the wiring and connections are periodically checked to maintain safety and avoid electrical hazards. It is important to change outdated parts as well so as to not cause additional harm to the system. Lastly, the use of smart controls that enable automated dimming or switching can help in preserving the lighting infrastructure by reducing their use.

Essential Maintenance Checklist

- ✓ Regular inspections for malfunctions

- ✓ Clean fixtures to maintain brightness

- ✓ Check wiring and connections

- ✓ Replace outdated components

- ✓ Utilize smart controls for automation

- ✓ Monitor energy consumption

When applied together, these methods and smart technology can help both industries and homeowners maintain the functionality and operational cost of their lighting systems.

Issues Commonly Experienced with High Bay Lighting Systems

One of the main problems with the high bay lighting systems is the uniformity of lighting in a large area. Since the lighting systems are placed at a great height, the light from the fixtures may not be evenly distributed resulting in areas with less or no focusing light and hence poor visibility. Another problem is the lighting running costs. As is well known, light fittings of such magnitude come with hefty energy bills, thus causing increased operating expenses for the company. As for the maintenance aspect, it is very challenging. Since the lighting fixtures are mounted high, maintenance is not easy, thus increasing the labor as well as the maintenance downtime.

⚠️Common Challenges

- Uneven light distribution

- High energy consumption costs

- Difficult maintenance access

- Heat generation issues

🔧Technology Upgrades

- LED system integration

- Smart controls implementation

- Motion sensors

- Automated dimming features

Another issue is addressing newer technologies like advanced LED systems and smart controls. These days, LED high bay lighting is being taken up rapidly due to their performance, cost saving, and energy efficiency. Older high bay lighting systems may not work with modern energy saving or automation systems. Thus, they will have to be upgraded to meet new standards, which is costly. To top it off, in many industrial setups demanding high temperatures, these high bay lighting systems tend to overheat, thus reducing their lifespans. Proper budgeting, maintenance, and selecting the optimal technology for a certain application go a long way in addressing these problems.

FAQ

Reference Sources

- PacLights – High Bay Lights: Lighting Explained

https://www.paclights.com/learning-center/high-bay-lights-lighting-explained/

This source provides a detailed explanation of high bay lights, their purpose, and their applications in large spaces with high ceilings. - Commercial LED Lights – LED High Bay Guide

https://commercialledlights.com/blog/high-bay-lighting/high-bay-buyers-guide/

This guide discusses the purpose of high bay lights, their design, and how they are used to provide vertical clearance and efficient lighting in industrial and commercial spaces. - TCPi – Benefits of Round High Bay Lighting

https://www.tcpi.com/benefits-of-round-high-bay-lighting/

This source highlights the benefits of high bay lighting, including energy efficiency, cost savings, and their popularity in industrial and commercial applications.

Conclusion

High bay lights represent a crucial advancement in industrial and commercial lighting solutions, offering unparalleled efficiency, sustainability, and performance for high-ceiling environments. From warehouses to sports facilities, these specialized fixtures provide the uniform illumination necessary for safety, productivity, and operational excellence. As LED technology continues to evolve, high bay lighting systems will remain at the forefront of energy-efficient lighting solutions, helping businesses reduce operational costs while meeting their sustainability goals.