In a highly functional warehouse environment, an adequate and efficient lighting system is a core principle. However, the icing on the cake is that the selection of the perfect solution might become a hard task because of the multitude of options currently prevailing. Out of the best standby options, UFO and Linear High Bay lights are indeed attractive due to performance and design, and because of their energy efficiency. However, how to decide on those that are to be positioned for a specific need in your warehouse? This article accentuates critical differences, unique characteristics, advantages, and potential applications between UFO and Linear High Bay lights. As advances happen, you will be in a better position to make the right decision concerning sturdy performance lighting versus those sensitive to meet operations.

Understanding High Bay Lighting

Best suited for spaces with high ceilings, high bay lights normally fall in the range of 15…40 feet and radiate superior, highly effective lighting, which ensures full coverage in areas with moderate to large dimensions like warehouses and manufacturing shops, and gymnasiums. They are designed to dispense illumination evenly around huge spaces, minimising shadows and enhancing visibility. There are two main types of these lights: UFO High Bays, which are compact and circular, and Linear High Bays, which are rectangular in design and may be more apt for aisle or row configurations. In all likelihood, the selection of one of these two models depends largely on the specific setup and lighting requirements that the premises necessitate.

What are High Bays?

High bay lights are a specific type of luminaire used in high-ceiling settings, usually between the heights of 15 to 40 feet. They are required to flood large areas with proper lighting while providing uniform distribution, brightness, and energy efficiency. Commonly, they are used in industrial and commercial facilities like warehouses, factories, and sports stadiums, which take advantage of the latest in optics to reduce glare and energy waste. There exist different models featuring different optics designs, from UFO to linear, with a variable range of applications suited to many forms and types of indoor space. Applied in robust environments, high bays are sturdy and durable lighting solutions for scaling lighting applications.

Types of High Bay Lights

There are a lot of types of high bay lights to suit the specific applications, lighting requirements, and environments for installations:

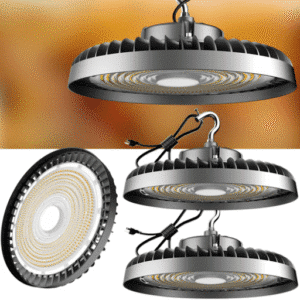

UFO High Bay Lights

These high bay lights get their name from their way-out and roundish appearance, which is quite compact and also highly energy-efficient. However, they could be an ideal option for warehouses, factories, and gymnasiums due to their focused beam angle and constant light visualization. As a rule, a die-cast aluminum shell is used to guarantee optimal heat discharge, thus indirectly increasing the bulbs’ useful life during difficult situations.

Linear High Bay Lights

These lights are used frequently in large spaces such as retail or industry, where illumination across a larger area is required. They give even light for the total area brighter than Highbay, also a good option for aisle lighting in the stockroom center lights. It is designed to fit well onto the grid-like configurations of many commercial buildings.

LED High Bay Lights

The LED high bay lights create an energy-saving, advanced form of lighting that provides that with high lighting quality. It comes in Linear or UFO shapes, with brighter light and low heat discharge. LED High Bay Lights last longer and offer dimming and smart control features, which make them versatile for use in today’s lighting systems.

Each type is beneficial in certain cases. The decision between a few is based on factors, including the ceiling height, area size, and intended use location.

Importance of High Bay Lighting in Warehouses

An essential component in warehouses where space is to be illuminated is the high-bay lighting system for illuminating large areas with a really high ceiling in the range between 20 and 40 feet. One common application of high bay lighting is to ensure a safe condition through accident prevention in areas where heavy machinery and forklifts are often used; another is improved productivity with clear visibility for inventory management, picking, and packing. Besides, high bay light solutions from today’s technology era, like LEDs, improve energy efficiency as the lights are put on for less time and require less power for the very high light level they give out. Therefore, the assembly of these lights assures better control over operational costs. Moreover, supplementary beneficial factors of effective lighting include improved levels of employee welfare and the reduction of office-related problems, such as eye strain caused by inconsistent lighting. The consideration of lighting should be in line with the kind of needs the warehouse has, as per the design, ceiling level, and kind of activities within it.

UFO High Bay Lights

High Bay UFO Lights have been created purposely for spaces that have ceilings of higher altitude, namely between 15 to 40 feet. They generally tend to be circular and designed for optimum light dispersion, something needed to provide the right illumination in large areas. They have a great energy-saving factor, and they usually use LED technology that reduces the overall electricity cost, which means fewer replacements will be needed. These fixtures are also long-lasting and easy to install in all kinds of settings, be it a warehouse, a gymnasium, or an industrial setting. They make for cost-efficient lighting solutions for large-scale applications, taking into account their lengthy running tenures and low upkeep requirements.

Features of UFO High Bay Lights

High Luminosity and Energy Efficiency

UFO high bay lights are designed to deliver high lumen output, allowing optimal brightness for spaces with high ceilings or large areas. These lights, which employ advanced LED technology, consume relatively less power than traditional light sources, bringing down operational costs and helping the environment as well.

Robust Build and Durability

The framework for lights makes use of high-quality materials, e.g., aluminum housing, for outstanding heat diffusion and corrosion protection. The sturdiness suits lights for rough industrial, commercial, or outdoor applications.

Wide Beam Angles and Uniform Illumination

UFO high bay lights distribute even illumination using precision optics over a large area. These are represented in beam angles and offer the ability to satisfy specific requirements of the lighting distribution design. No special maintenance is required for them.

Main PIR and Remote Control Systems

Modernity best describes UFO high bay lights, unbeatable for their compact and light design in comparison to other lights. This makes the installation of high bay lights convenient not only at an unimaginably quick pace but also makes it quick and easy. Additionally, the longevity of these high bay lights is no minor convenience—it spares the maintenance requirements a long way, with the hours almost always exceeding 50,000. Another attribute ensuring their market acceptance is that the potential for any dispute arising relative to product-advertisement claims is definitely null, as it will not ever fail later.

An Inventory to suit any enterprise and Luminosity control

Dedicating a minor note: any UFO high bay model comes pretty compatible with dimming control and motion sensors, which in turn bear customized settings to surge in energy efficiency. Thus, it can be fitted into areas such as warehouses, factories, gymnasium systems, and retail spaces.

This sort of efficiency, life, and compatibility clearly manifest the UFO high bay lighting system since the lighting system exhibition compares with contemporary proficiency.

Benefits of Using UFO High Bays

Uplifting Energy Efficiency

UFO high bay lights utilise the latest LED technology, which significantly reduces energy consumption compared to conventional lighting systems. What distinguishes this efficiency is decreased electricity charges and a reduction of carbon emissions, both of which add to sustainability.

Incredible Longevity

Durably constructed, UFO high bay lights have an average life of 50000 hours, expected when working under optimal conditions. This dwindles the specificity of delivery use while decreasing maintenance and repair costs for good efficiency in utilization for large-scale applications.

High-Quality Illumination

UFO high bays deliver illumination on their lumen output, and in color rendering distinctions, there is a bright uniformity that will improve visibility within various trading and commercial environments. This safely and efficiently supports and enhances performance for the dual advantages of employee and client well-being for significant business production.

Strong constructions.

These lights are engineered in a way meant to withstand tough conditions, with an IP65 or higher rating for dustproof and watertightness. Therefore, they become perfect for applications such as warehouses, factories, biosafety labs, or even outdoor installations where endurance becomes a critical piece of investment.

Smart Technology Integration

Many times, UFO high bay lights come with new-age features like dimming, motion sensor pairing, and programmability. These functions allow for additional savings on the part of more precise customization.

With the benefits of this new technology, UFO high bay lights, in fact, are highly efficient, reliable, and versatile, designed for more or less heavy-duty lighting tasks in different industries.

Ideal Applications for UFO High Bay Lights

UFO (also known as “Round 2”) high bay lights are specifically intended for high-ceilinged, open spaces requiring powerful and efficient lighting. One of the reasons why these fixtures are so popular is that they are designed to fulfill their responsibilities for a long time and under any challenging condition with their compact arrangement and advanced optical characteristics. Practical uses would include:

Warehouses & Distribution Centers

UFO high bays are popular for such spaces with high ceilings and enormous floor plans, where uniform bright light is highly essential. Similarly, its energy-efficient nature/check on power consumption, or long life combine to further shave off operating costs within these industries that operate around the clock.

Manufacturing Centers

Manufacturing facilities need a great deal of light for the proper visibility of assembly lines and machinery, for the promotion of workplace safety, and for optimal control. Due to high ratings on dust and vibration resistance, these lights qualify for their survival-impact use in the competing manufacturing sector.

Gymnasiums and Sports Arenas

In large spaces, such as gymnasiums and arenas, UFO high bay lights are built to provide very high lumens so that the area receives illumination, which is necessary for sports and other events; on the other hand, these carry less glare and resultant shadow issues.

Retail Stores and Supermarkets

UFO high bay lights bring a well-lit, warm feeling and yet conserve energy in large store-type spaces.

Cold Storage and Food Processing Facilities

The operating capability in very low ambient temperatures and high humidity levels makes these lights particularly attractive for use in cold storage and over/in food processing areas that require stringent lighting requirements and where reliability is of the utmost importance.

The lighting fixtures and devices utilized by this industry are unparalleled from every point of view, suggestive of their essential efficiency within diverse industries and applications.

Linear High Bay Lights

Linear high bay lights can be very well suited to lighting purposes aimed towards wider spaces by delivering a uniform distribution of light. They will find the best usage in huge warehouse sites and other storage facilities and structures where high-quality, continuous lighting is a prerequisite. Ensuring energy preservation, this feature-level crosses over base functionality to cut costs on utility bills and ensure good quality, bright light in any customer access spaces. Being linear in configuration, these types are more suitable for smoothly spreading the light in narrow aisles and layouts. Showing better reliability and longevity relative to other light sources, they are a good choice for settings that ask for good light spread obtained inexpensively for a very long period.

Characteristics of Linear High Bay Lights

Linear high bay lights are precisely engineered lighting solutions designed for considerable indoor spaces that have relatively high ceilings, around 15 to 50 feet in height. They can be easily recognized by an elongated, rectangular design that provides wide and uniform light distribution, which is especially beneficial for aisle setups and large open areas. The utilization of LED technology in these lights guarantees energy efficiency superior to traditional HID or fluorescent fixtures, which cuts power consumption substantially. On top of this, they have high lumen output to ensure levels of illumination suitable for large open spaces, massively reducing energy costs.

Due to their strong and durable nature, these lights are built with sturdy materials that can carry heavy industrial or commercial power users, being that they have to survive in conditions with dust, vibrations, and potential impacts. Some kinds confer deluxe features encompassing dimming, motion sensors, or programmable controls. As well, one of the key attributes of these superior linear high bay lights is a high color rendering index (CRI 80+) for a great and precise vision for tasks that demand fine detail.

Mounting is easy due to the choice of suspension kit, surface mount, or chain mount for installation, depending upon the structure. Also, they are mounted with the promise of low maintenance, keeping the lamps running for an impressive life of 50,000+ hours, leaving not much to fret over, reducing the time the light is out, and reducing any replacement cost. All in all, linear high bay lights are a fair choice for businesses looking to optimize lighting efficiency in large areas.

Advantages of Linear High Bays

Linear high bay lights offer many benefits that place them at the front of the line for industrial and commercial lighting applications. They are superior in terms of energy efficiency, a result of their application of LED technology. This cuts down on power consumption by a significant extent when compared to conventional fluorescent or metal halide ones. In the long run, this saving in energy will lead to substantial cost savings. These linear fixtures also come with brilliant light output with uniformity, introducing an overall well-lit environment good for visibility, productivity, and safety. With a modular design, they can easily be controlled through advanced lighting systems such as dimming or sensors to ensure power efficiency.

One of the main assets they have is their ability to endure and serve for the long term, with life spans beyond 50,000 operating hours, requiring minimal to zero level of maintenance and subsequent labor costs. Linear high bays feature high-tech cooling systems to help defeat overheat issues, hence increasing the life and durability of their performance. Here, wide versatility presents itself in a series of industrial-grade light sizes, beam angles, and mounting options, catering to different ceiling heights and structural layouts. This capability ensures adaptiveness among warehouses, gymnasiums, manufacturing plants, and other large facilities. Lastly, the linear high bay has little impact on the environment, as in terms of lighting solutions, it is ecologically responsible due to its low energy consumption and environmentally-friendly manufacturing processes.

Best Uses for Linear High Bay Lights

Linear high bay lights are best suited for the requirements of efficient and high-intensity illumination in vast, wide-open spaces. A quite common use of these lights is in warehouses where the longitudinal configuration is such to ensure the even distribution of light along the aisles and shelving, which improves the visibility and safety of workers. At the same time, they help in illuminating the environment for athletes and spectators in gymnasiums with an even and glare-free distribution that enhances the entire visual experience. Yet another point is the potential of these lights for megawatt illuminations in providing instrumental for efficient illumination across large interior spaces, crucial for the long-and-late operating hours of manufacturing facilities. Furthermore, retail spaces with soaring ceilings are surely eyeing linear high bay lights to create environments. The versatility and adaptability of linear high bays make them an ideal solution for various industrial, commercial, and recreational purposes.

UFO vs Linear High Bay: A Comparative Analysis

In such a comparison between the UFO and Linear High Bay lights, the principal considerations would be the application, design, and performance. The UFO High Bay lights are round and petite, a configuration good for places subject to high ceilings and requiring concentrated lighting. This can be seen in warehouses, factories, and gymnasiums, where these lights provide more focused illumination over smaller radii and are very durable, usually with IP ratings for both dust and water protection from outside elements.

Linear High Bays are usually selectable for some broad mixed uses, offering fairly widespread, uniform illumination of a relatively larger area. The spreading works much better for spaces such as retail stores, assembly lines, and storage facilities that need more extensive coverage. Most of them distribute light more uniformly when compared to the UFO models.

The choice between UFO LEDs and Linear High Bays depends on a specific lighting need. UFO will be more of a service for focused, high-intensity illumination, whereas Linear High Bay is practical in applications that demand wide and even lighting.

Lighting Efficiency

Lighting efficiency factors largely determine the performance and energy consumption in high bay lights. Lumens per watt (lm/W) signify how effectively a light source transforms electricity into visible light. High bay LEDs boast above-average effectiveness, which is better than what conventional lighting technologies, such as high-pressure sodium (HPS) and metal halide (MH) lamps, offer. This is because LEDs for high bay tend to be well above 100 lm/W and, in the best case, up to as high as 130 lm/W, far superior to the 70-100 lm/W of older systems.

Efficiency determinants, such as LED chip quality, driver technology, and thermal management features, are effective in designing LED high bay fixtures; such fixtures correspond to zero-loss energy and offer steady efficacy throughout the better part of their lives, thereby reducing the number of replacements and already setting the stage for long-term cost savings. Efficient energy use can be further improved by making fixtures dimmable and able to work with motion sensors to allow precise control over luminance when and wherever necessary, thereby ensuring that no light energy is wasted in such places. High-efficiency light fixture choices save businesses money, reduce environmental impact, and comply with increasing energy regulations.

Installation and Maintenance Considerations

Good installation of a high-efficiency lighting system ensures its maximum efficiency and longevity. The current electrical infrastructure must be evaluated to determine whether the new system is compatible. Professional installation is the wisest choice so that you will prevent any question of applications, which is are too serious a mistake in light efficacy. Installed lights may be well-situated so as to promote light diffusion but minimize glare or shadowing.

Maintaining a fixed schedule for cleaning the fittings against dust, and for periods to prevent light scuffing, is one’s responsibility. For LED types, they should consider monitoring fixes that indicate a failure soon, like flickering or dimming; they can step in and seize the opportunity to avert the failure. An evolving system like this should always undergo updates in terms of firmware to retain consistency and functionality. Establishing a preventive inspection schedule will spot and solve any potential problems, thus extending the useful life of the installation.

Cost Comparison

A formula for validating lighting installations involves costs both for initial investment and for the long run. Any LED lighting system will have higher upfront costs over time compared to the traditional lighting options: a handful of incandescent or fluorescent lamps. However, these trades nonetheless save on energy and last long. On average, LEDs use 75% less energy and last 25 times longer in hours compared to incandescent bulbs. Hence, this diminishes costs for repurchasing the lamps. Smart or intelligent lighting is able to save even more money since it can control energy usage much more efficiently by incorporating all functions into the technology, i.e., motion sensor and programmable features for the lights. Reduction of energy consumption will show great expense savings in the long run for smart fixtures because even the initial high costs of installation would very soon be evened out by gains on energy savings. Likewise, government schemes, recompensing or offsetting the cost of installing based on energy-efficient devices, also form a monetary relief which is expected to enhance the overall financial feasibility.

Making the Right Choice for Your Space

If you wish to select the correct lighting solution for the given interiors, energy saving capabilities, long-lasting performance, and several other utilities should be deeply considered. LED lighting typically proves to be highly efficient due to its low power consumption and unrivaled durability while requiring only minimal maintenance. For added resilience, a smart type luminaire equipped with motion sensing and other programmability features would greatly enhance the yield between energy and its effective utilization. Check government offers and incentives to see if energy-efficiency modifications may be beneficial to help offset the expenses. Strictly understand your inferred requirements: for basic requirements, levels of illuminance, design latitude, and use pattern characteristics are to be recognized; all these have to combine for both aesthetic and technical reasons.

Assessing Your Lighting Needs

Initially, you must identify the purpose and goal of each part in your living or workspace while evaluating your lighting requirements effectively. Places requiring the most light may be kitchens and/or offices, where lumen output should be high for good visibility to boost productivity. Warmly lit, dimmable lights should be aimed at bedrooms and family rooms that soothe.

Evaluate the amount of illumination that a given space needs in conjunction with the size and layout of the room. Cooking or work areas with good lighting demand a background layer that enhances visibility and adds another layer, such as a task light or accent light at the countertop locations. Upon evaluating the natural light sources in the room, it will give a random idea as to what artificial lighting may be allowed and at what level at various times of the day.

The prime concern to consider when deciding upon light fixtures is energy efficiency. LED bulbs, for instance, are far more economical and also last longer compared to the traditional incandescent or fluorescent light sources. In other words, consumption and protection of the environment find the quickest payback these days. The selection of the color temperature of the light source (in Kelvin, K) interestingly matches the intensity of different activities. Work areas are more suitable for cool tones (4000K–5000K) and living spaces for warmer tones (2700K–3000K).

In addition, choose some innovative technology when one desires to tighten control and customization of the lighting. These systems are usually programmable, allowing you to define different schedules, control from one’s remote, and integrate with other smart devices. Reflect cautiously on these points to craft a lighting strategy uniquely balanced in functionality, aesthetics, and cost efficiencies.

Warehouse Aisles and Lighting Solutions

While thinking of lighting solutions for warehouse aisles, I would focus on systems that assure visibility, safety, and energy efficiency. Linear LED luminaires and high-bay LED luminaires are good for offering uniform illumination for long, narrow spaces. By including motion sensors and dimming controls, the energy savings can be maximized by providing just enough light for each application. So, then, I have to consider the layout and height of the ceiling in the aisle, in deciding which light beam angles and how many lumens are appropriate, so each area will have even illumination but without any glare. These would be the five key aspects to designing a practicable, affordable lighting setup.

Expert Tips for Choosing Between UFO and Linear High Bays

Choosing between UFO and Linear High Bay lighting options calls one to look into the needs of the particular space. UFO-type High Bays are more compact, tough, and adept for use in locations with high-ceiling levels, like warehouses and factories, where the light dispersion in a more 360-degree radius is much more useful. Their rugged housing also provides more resistance to dust or moisture, so these luminaries are very suitable where industrial safety takes precedence.

Linear High Bays, meanwhile, do well in applications asking for uniform lighting over a more rectangular area, such as in retail environments, gymnasiums, or assembly lines. So, since their length runs more along the line of extensive light coverage, scatter-blocking, and uniform spacing across aisles or large spaces are allowed simultaneously. Additionally, with a linear light fixture comes the attractiveness of integrating with commercial settings with their elongated and modern look.

On the same note, installation and maintenance questions should not be ignored during any discussion over which luminary lights should be mounted in the project. UFO High Bays are generally easy to install by way of their minimal length and single-point mounting, whereas Linear High Bays may require additional support for achieving equal weight distribution. The requirement for lighting layout, ceiling height, and usage thereof will direct you to the best choice made perfect for your specific environment.

Reference Sources

Frequently Asked Questions (FAQs)

Versus linear high bay lights: What is the suggestion for my warehouse lighting?

Deciding upon UFO high bay versus linear high bay lights takes into consideration the ceiling height available, the layout of the space, as well as just how much light you need. The high bay LED lights in a circular flying saucer design (UFO LED high bay) have a solitary light; it courses upwards in a circular fashion and thus emits a fan-shaped light. This one is suitable for a particular region of lighting, a single spotlight, as can be seen in picture entertainment such as theatres and stage performances. Alternatively, the LED linear high bay, or long linear fixtures that generally produce a rectangular light pattern and sustain the same light from one end of the lamp to the other, are better in offering overall uniform illumination down aisles or throughout open areas. If a rack configuration is to go into a commercial or industrial space, in that case it needs to be considered whether the circular light of a single light or multiple linear lights will be the most constructive lighting design concept and help you make an informed decision.

UFO High Bay vs: How does heat dissipation and heat sink design compare?

Presently, most UFO high bay light insides are constructed with a bulky heat sink designed in the shape of a UFO, meaning that heat is effectively dissipated under a small form, having the simplicity of a cordoned off LED high bay light. A line light, therefore, gathers elongated heat sinks on the entire length of the fixture, spreading the heat across an area larger than the previous. This expands the lifetime of lumens while adhering to thermal management quality and the heat sink before buying the right lighting for some commercial or industrial projects, making the lights appear better than old metal halide options, performance-wise.

Which one is a better option for lighting up warehouses: Circular light from a UFO or an elongated horizontal beam from linear?

The design of the Highbay Light Linear LED Light reflects the orbicular form of the UFO LED High Bay Light and provides a specialization of light onto different regions. Perhaps it may not be a perfect square, but the light from the linear LED high bays is one that gives less of the harshness and reflects a better uniformity when compared to over-illumination or bright spots on walls, with the light that gets spread across shelves and thoroughfares. Will it be enough to weigh your space layout against the direct or spread-out light effects, or is some other way even more of an issue for you to consider? Often, in narrow aisle operations, a linear fixture is better given the long corridors.

narrow aisle: Should I choose UFO or linear for narrow aisle warehouse runs?

Within high, narrow aisle spaces, light must be uniform from one end to the other to minimize shadows and improve the product visibility. This is what makes linear LED high bay replacements or long linear designs pleasant: the uniformity of an aisle from end to end, and it is ideal for hanging them from two hanging points using chains for stability. However, in the very tall, narrow aisles, stacked UFO high bay lights can still be used if spaced correctly; the trick is to balance the quantity of light to avoid bright spots on the wall.

Different illumination: The advantages and disadvantages of two popular LED designs?

Two designs have mainly garnered widespread popularity: the UFO High Bay and the Linear High Bay. UFO fixtures are smaller, with the ease of installation in a single act of the light, and virus-like heat sink integration, whose shape is that of a flying saucer. The Linear fixture illuminates its own purpose for prolonged lighting, specifically for rows of rack shelving and workbenches. UFO high bays will work well for calculations or tasks, areas with an open floor plan, while linear lighting in general works more than a one-dimensional flood of light. Your point of consideration should involve how the lights are being hung (one or two) and the angle of light intensity (60 ° or more), and what kind of visualization you wish to achieve in the lighting project.

Lighting specialists: How are the ceiling lights and the mounting types going to perform?

Installation issues come into play: simple to install and position, UFO high bay lighting is mounted using one point or hook, while LED linear high bay fixtures are mounted using two points and are held in place with chains or brackets for stability. Ceiling-mounted lights directly deliver light to the floor and shelves and, at the same time, eliminate excess glare. Custom designs from expert lighting designers provide expertise in order to secure optimal hang arrangements and suitable beam angles to achieve the best results and properly light up your commercial or industrial space.

vs linear high bay lights: How do these compare to old metal halide in terms of energy and light quality?

Compared to traditional metal halide lights, the LED high-bay lights provide immediate start-ups, higher efficacies, and longer life times with much less maintenance. Both the UFO LED high-bay and linear LED high-bay fixtures deliver greater lumen output per watt and lower heat production, leading to energy savings and cooling loss mitigation. LEDs provide the potential for tweaking color temperature and distribution to meet more fully the requirements of modern industrial lighting projects where strong, uniform lighting is equally relevant to energy efficiency.

LED high bay vs linear LED high bay: What to consider for your commercial or industrial space?

To reach an educated decision, consider the layout of your space, the type of tasks being performed, and several criteria such as the amount of light required, uniformity of light, heat dissipation, and installation preferences. Lighting calculations or a partnership with an expert in lighting consulting can help you compare scenarios. One possibility would be to choose UFO for high ceilings with highly focused circular beams or frost linear, where narrow aisles and long runs necessitate rather uniform light. Consider also surface finish, saucer shape versus long elongated light, and consider practical details like hang points, sink quality for dissipation of heat, or maybe just as to light fixtures that offer the best lighting solution to a given project.