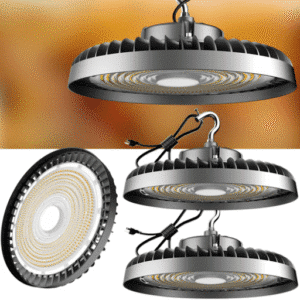

Overview of UFO High Bay Lights

UFO high-bay lights are modern, efficiently designed lighting solutions for use in large spaces with high ceilings like warehouses, factories, and gymnasiums. Their sleek and compact round design affords the highest degree of illumination across vast spaces, while obliterating shadows. It also supplants traditional, but now qualified, counterparts with LED-like tech for unparalleled energy efficiency, so the operating cost is lower with longer-lasting fixing capacity. In addition, UFO high-bay light fixtures excel in lumen output and brightness control, where such bare illumination would be suitable for environments necessitating the utmost in sufficient and top-quality lighting.

What are UFO High Bay Lights?

Circular, compact LED lights of the UFO high bays are designed for high ceiling spaces, usually ranging between 15 and 50 feet. The disks help the proper lumen disbursement and ensure their durability. The UFO high bay lights utilize advanced LED technology to provide good lumen output with minimal energy consumption, making them desirable in place of traditional HID, metal halide, and fluorescent lighting. Often, UFO high bay lights are found in warehouses, industrial facilities, gymnasiums, and large retail stores, where they provide a considerable amount of energy efficiency, life span, and low maintenance costs. Conversely, since most UFO high bays have a very hard metallic build, they usually house very high-quality IP ratings for good resistance against dust, moisture, and bad weather.

Advantages of Using UFO LED High Bays

Size and Appearance

These lights are fairly slim and lightweight, which makes installation easier in contrast to traditional lighting technology. In addition, the extra space saved can accumulate light in a confined manner to allow more luminosity. The UFO dimension is also beneficial because it minimizes the other design limitations.

Purpose and Efficiency

UFO LEDs are not made to win beauty contests, but they are naturally perfect for illuminating vast spaces. The LEDs are rigged with the latest chipset technology, which guarantees that the light flux travels directly from the surface to the work area. This feature allows for a working environment that is zoned with sufficient lighting without affecting the surrounding areas.

Life expectancy and Energy Efficiency

UFO LED high bay lights are a clear winner in terms of saving energy. As they are quite efficient in their operations, they generate 60-70 percent energy savings. At the same time, traditional lighting systems such as HID or fluorescent bulbs acquire considerably higher energy wastage along with heat loss.

Brightness and Energy Durability

The UFO high bay lights will last longer and save a lot of energy losses attributable to heat fading. They come with high ingress protection indexes, so they can fight back against dust, moisture, and harsh temperatures, with all their durability, showcasing their suitability in a tough industrial and commercial environment.

Eco-friendly

As against all the past lighting, UFO LED high bay lights are free from mercury and emit less heat. Sure enough, they could be known for drawing less carbon footprints on board respective sustainability programs and policies.

Customization Options

One feature that often comes with UFO LED hibay lights is dimming capability, along with some other basic features such as motion sensors or adjustable beam angle, for a custom-designed lighting solution tailored for their essence and an energy efficiency measure in several cool applications.

Applications of High Bay Lighting

High bay lighting is intended for areas that have high ceilings where the required illumination is strong and uniform lighting, typically from 20 to 40 feet. Some of the most common applications are:

Warehouses and Storage Facilities

High bay lighting provides consistently bright illumination to navigate larger storage areas, all while promoting safety and productivity. Energy efficiency and a long lifespan are pivotal for sustaining excellence in such energy-consuming environments.

Manufacturing Plants and Industrial Facilities

High levels of light are necessary in these work environment conditions so the work can be done quickly with an unfading string of light under machinery work and safety constraints. Embedded LED high bays catch all categories of lights and stand up under environments with a lot of dust, vibration, and extreme temperatures!

Gyms and Recreational Facilities

High bay lights provide even illumination for athletes and spectators. Little brightness and glare, while offering good visibility.

Retail and Commercial Spaces

High bays are beneficial for large establishments since they give the required visibility for merchandise display and also encourage an almost welcoming atmosphere. Motion sensors go a long way in saving electricity, too.

Airports and Hangars

Maintenance is important to ensure that airport facilities are in good working condition at all times. Hangars can be large and usually require maintenance services throughout the year. High bays help to illuminate such large areas with the required precision and clarity while conforming to strict safety and efficiency standards.

Convention Centers and Exhibition Halls

Such spaces demand broad and homogeneous illumination for a varied arrangement of designs and for a large public. High bays are able to accommodate such needs by offering adjustable beam angles and dimming capabilities.

Its adaptability, efficiency, and long life make high bay lighting a prime solution for a broad range of industrial, institutional, and recreational applications.

Types of High Bay Lights

| Type | Description | Key Characteristics |

|---|---|---|

| LED High Luminaires | It is the most energy-saving and long-lasting way to provide excellent levels of illumination | Low heat discharge and reduced energy costs |

| Fluorescent High Luminaires | The light fixtures are inexpensive to acquire but capable of providing decent efficiency | Suitable illumination option where the proposed project lies within budget constraints |

| Metal High Luminaires | Although the light sources are bright and hardly flicker | They gobble much more power and have much less longevity compared to LEDs |

| HPS High Luminaires | Warm in color, energy-efficient | Optional for some types of lighting, not quite bright enough for many types of lighting |

These types of lights were selected using their energy consumption, brightness, color rendition, and lifespan to fit the needs imposed by individual premises.

Understanding Different High Bay Fixtures

Before its final selection, many things need to be taken into consideration to get an optimal performance and cost-effectiveness, among them.

Energy Efficiency

LED is the highest choice in terms of energy efficiency; most manufacturers conserve much less energy than the improved contrast and technology over metal halide and high-pressure sodium (HPS) luminaires. This is especially good in operational costs and large facilities where lighting is used for long periods.

Lifespan and Maintenance

LEDs on high bay lights outshine metal-halide lights, surpassing 50,000 hours in service. This by itself misses out on increased maintenance intervals and costs when compared with a metal-halide source.

Brightness and Quality of Light

LEDs provide superior brightness and very high color rendering, which is perfect for areas that require high visibility and accuracy. Metal halide lights have a lifeline but cannot by any means match the brightness and running energy usage of the LEDs, while HPS lights might be cost-effective, but at the same time, they might lack the clarity needed for certain applications.

Environmental Significance

LED lights respect the environment through their low energy consumption compared to the wasted energy. On the flip side, typical metal halide and HPS lights tend to consume more energy and waste more too.

Making the right selection of a high bay light fixture revolves around achieving the balance set by these considerations and fulfilling the needs prescribed by the facility, for example, desired light intensity, usage hours, and practical economic assessments over time.

Comparing UFO LED High Bays and Other High Bays

Regarding certain essential considerations like the quality of light, UFO LED high bays are the solution when it comes to energy efficiency in comparison to outdated high bay light technologies like Metal Halide (MH) and High Pressure Sodium (HPS).

Energy-efficient lighting

UFO LED high bays are far more energy-efficient compared to MH and HPS fixtures. LED lighting requires much less power than does any standard system, translating into energy savings of up to 50-70% and illuminance-equivalently brighter lights. The lumens per watt number is much higher on these fixtures.

Long-lasting and low maintenance

The longer lifespan of these LED fixtures is generally rated between 50,000 to 100,000 hours, standing taller than the 10,000 to 20,000 hours range set by Metal Halide and High Pressure Sodium. This longer lifespan minimizes maintenance intervals and costs, particularly with fixtures installed in places with higher ceilings or less accessibility.

Quality of Lighting

UFO LED high bays have the highest light quality, CRI, which is for improved clarity of color vision and color rendering. Furthermore, it blinks instantly without any warm-up period required by metal halide or high-pressure sodium lamps, making it perfect for applications where illumination is required without delay.

Environmental Impact

LED technology is more environmentally friendly due to the low energy consumption and absence of hazardous mercury, typically present in other lighting sources such as metal halide and high-pressure sodium lamps. LED technology is free from getting hot or generating heat and hence does not contribute to cooling costs.

Cost Implications

Their initial install cost is still higher compared to traditional systems, but they carry long-term energy savings, lowered maintenance, and credits against their cost advantage in favor of having a lower total cost of ownership over a reasonably long period. The return on initial investments from its installed UFO LED high bay takes only a year or two for several installations to turn the benefits for the customers into revenue.

UFO LED high bays and other high bay selections are the two biggest contenders in the battle for supremacy. Generally, we always have to presume the lighting requirements in the application. Light quality, energy efficiency goals, and long-term cost implications should come into play in choosing dome LED versus some poor LED or LED problem. So, it is easy to know that UFO LED high bays are a perfect choice that showcases these advantages.

Linear High Bay vs. UFO High Bay Lighting

When juxtaposed with linear high bay and UFO high bay lighting, each form stands out by appealing to specific characteristics, according to the application and environment in question. The linear high bays are suitable for areas meant to be illuminated widely and uniformly, such as warehouses, retail stores, and production lines. The long stretch and the considerable beam angles render these efficient for long stretches, an armada of light distribution for large, rectangular dim areas with minimal shadows.

On the flip side, UFO High bays contribute to the cinema of light, which spreads better than a circular design and focuses on widespread light with a slight beam angle. This makes them better suited, when considering lighting concerns, for tall buildings, including situations when you only need a specific area illuminated, such as factories or gymnasiums. They are hardy, built to weather rough times, and are often able to stand the heat and other conditions like dust and moisture, thanks to high IP (Ingress Protection) ratings.

From the perspective of efficiency, LED variants are typically the way to go in both high bay configurations, as energy consumption and offender costs through energy will subside meaningfully. However, UFO high bays tend to be a bit more on the efficient side, especially considering their concentrated light design, causing less dissipation of light. In the end, the best choice between the two depends on the layout of the building, preferred light dispersion, and manual goals. UFO high bays may be the optimum choice for applications with high ceilings and needs for concentrated alignments, while the broad surfaces calling for end-to-end illumination fall for linear high bay fixtures.

LED High Bay Lighting Benefits

- Energy Efficiency: Less power is consumed than in a variety of traditional luminaries; that implies reduced electricity bills and sustainability.

- Longevity: A life expectancy that stretches up to 50000 hours or more translates into reduced periodic maintenance and related costs.

- Quality Lighting: These fixtures deliver consistent and high-quality light with effective color rendering and very little flicker, which leads to improved visibility and a safer working environment.

- Cooling: Running with low heat, more comfortable than the rest of the old versions, which generate excessive heat, thereby saving on cooling costs.

- Versatile: Multiple designs and beam angles present the ability to increase efficacy on different locations, adjusting light distribution according to different personal requirements.

Energy Efficiency and Cost Savings

LED high bay lighting is a highly efficient choice for high energy and cost savings. They consume about 75% less energy than traditional paradigms (e.g., metal halide or fluorescent fixtures) for the equivalent lighting capacity. Furthermore, the manufacturer approves the efficiency with over 50,000 hours of life, which indicates very little maintenance cost. Moreover, with LED technology, the use of advanced dimming and controlled systems enables the fine-tuning of energy usage to be triggered by occupancy or light level. All these results go together, leading to a favorable AMC in application for these areas.

Longevity and Maintenance of LED Fixtures

LED fixtures are famous for their remarkable lifespan, which could conveniently range between 50 and 100,000 hours depending on usage and environmental conditions. A huge chunk of the blame for this durability falls on low thermal losses due to an efficient heat dissipation technology, so consequently lesser amount of their ingredients degrade in the diode material.

An added benefit is the least amount of maintenance necessary owing to their sturdy design, which is resistant to shock and vibration, and, of course, easily shrugs off high-altitude assassins. Incandescent lamp degradation is short-lived and explodes like an “accident,” whereas the lesser brilliance with LEDs implies that one can mentally prepare to replace them at an advanced stage when possible. Often, modular parts design allows for simple repair or upgrade instead of complete replacement, minimizing downtime and costs.

Due to its intelligent remote-control and escudulent monitoring functions, not to forget the mostly remote performance tracking it enables, allows a facility to indirectly anticipate any irregularity like dirt or wear that might be going on and maybe causing trouble. In such a proactive maintenance admin expert, a constant level of illumination and steadfast performance throughout the entire fixture life can be anticipated. All things considered, this demonstrates boldly that generally LEDs will significantly serve industrial and commercial spaces over time, fully providing a cost-effective and sustainable lighting solution.

Environmental Impact of LED High Bay Lighting

LED lighting equipment in high bay has created significant environmental advantages when compared to conventional lighting technologies like fluorescent and HID fixtures. Firstly, for one, LEDs use much less power, and the resultant load on electricity grids shrinks by up to 70%. So, if less energy is used, the electricity generation itself will also see fewer emissions to increase the pleasure of a wise, long-term mentality. In this way, LEDs contribute to the reduction in the amounts of waste produced on account of their longer life; more than 50,000 hours of activity is incalculable. Finally, the low levels of lead, thereby a reduced risk from disposal, sizeably alleviate concerns relative to disposal and potential for environmental contamination.

What’s more, most LED lighting systems are used with a directed nature that, to or lesser extent, combats light pollution. Many modern LED light fixtures are manufactured using recycled materials, which makes them extremely appealing for energy savings throughout their life cycle. Hence, LED high bays contributed to the environmental value-permission industrial/commercial applications by their carbon footprint reduction, with energy efficiency and sustainability as values equally honored.

Lighting Design Considerations

In industrial and commercial settings, it is important to first examine illuminance, efficacy, evenness, and other requirements. The general task that lighting serves in a given space is determined by task lighting requirements, high-visibility locales, and so on. Opt for luminaires that deliver high energy efficiency, such as LED sources, which obtain the highest lumen and efficiency levels and thus reduce operational costs the most. It is also important to distribute the light uniformly to fully eliminate shadows and glare, which, in turn, will improve the safety and productivity of the workspace. For the long-term performance and sustainability of the fixtures, the finishes, durability, and maintenance requirements of the fixtures selected need to be taken into consideration.

Planning Your High Bay Lighting Design

In laying out your high bay lighting design, one would like to address several concerns to ensure the best results are achieved. For starters, calculate the right amounts of lumens based on the size, height, and purpose of the facility. For typical demand, a warehouse will need around 10,000 to 20,000 lumens per fixture; a manufacturer could require more depending on the specificity of the task.

The next thing to contemplate would be the beam angle of the fixture. Narrow beam angles (60° or less) will do well in tall ceilings, used predominantly in the industrial sector, to concentrate the light on specific areas. Wider beam angles (90° to 120°) are loved for their diffused lighting in locations that need wider visibility.

Also consider the energy efficiency of LED high bay lighting selection. With a higher energy efficiency, LEDs will help minimize heat production and operational costs. LEDs have a lifespan typically extending to 50,000 hours, thereby considerably reducing maintenance obligations.

Consider consistency in lighting distribution in operations. Photometric studies or simulation tools work very well in evaluating how the lights are arranged in space, to ensure every dark spot is overshadowed with uniform illumination. Incorporating fixtures with controllable dimming or those with automatic switches is one way of improving efficiency against varying operational conditions.

It is essential to also consider environmental issues such as temperature, dust, and moisture, even as we evaluate the factors mentioned earlier. Go for fixtures rated for particular IP environments in harsh surroundings; this is a sustainable way of guaranteeing safety, durability, and smooth compliance with standards, making the products reliable in the face of time and change.

Factors to Consider When Choosing UFO LED High Bay Lights

One of the many key aspects to evaluate and ensure maximum performance in UFO LED high bays is lumens and wattage:

- Lumens and wattage: Your lighting should meet the required lumens output for the endpoint they service. Higher lumen output will be required in mounting locations with higher-than-average ceiling heights, i.e., more than 15 feet or more. Wattage levels will have to be balanced such that brightness and energy efficiency are matched, since LED outguns the rest of traditional lighting technology in that area, as it offers more lumens per watt.

- Color Temperature: Color temperature has a direct impact on the visibility and productivity within a space. For industrial, warehouse illumination, and the like, the color temperature should be in the range of 4000K to 5000K for a daylight-like function, which awakens clarity with fewer effects on the human mind’s optical strain.

- Beam Angle: High bay lights with 60° and 120° beam angles decide how light is emitted. Narrow beam angles (e.g., 60°) will focus light on specifically targeted areas by limiting the spill light. In contrast, wider angles (e.g., 120°) broaden coverage of light in open spaces.

- Lifespan and Energy Efficiency: This is also a medium involving dimming controls, gentle adjustment from motion structures, and better alarming structures that can reduce or enhance management energy savings according to necessity, such as in the case of industrial, retail, or warehouse facilities.

- Highness Analysis: Look for high IP fixture grades to guarantee the safety against dust and water in rugged environments (i.e., IP65 and higher). Furthermore, an aluminum body ensures better heat dissipation, leading to longer LED lighting lives.

- Return on Investment (ROI): As compared to conventional lighting options, the cost of LED high bay lights might appear initially higher, yet you can determine your ROI in detail based on energy savings, lessened maintenance, and an extended life span. Generally, most establishments can record handsome savings amounts in the long run.

- By having more to take into serious consideration on these parameters, you will successfully land on just the ideal UFO LED high bay lights for your particular application needs, allowing for a combination of performance and longevity.

Factors to Consider When Choosing UFO LED High Bay Lights

One of the many key aspects to evaluate and ensure maximum performance in UFO LED high bays is lumens and wattage:

Lumens and wattage

Your lighting should meet the required lumens output for the endpoint they service. Higher lumen output will be required in mounting locations with higher-than-average ceiling heights, i.e., more than 15 feet or more. Wattage levels will have to be balanced such that brightness and energy efficiency are matched, since LED outguns the rest of traditional lighting technology in that area, as it offers more lumens per watt.

Color Temperature

Color temperature has a direct impact on the visibility and productivity within a space. For industrial, warehouse illumination, and the like, the color temperature should be in the range of 4000K to 5000K for a daylight-like function, which awakens clarity with fewer effects on the human mind’s optical strain.

Beam Angle

High bay lights with 60° and 120° beam angles decide how light is emitted. Narrow beam angles (e.g., 60°) will focus light on specifically targeted areas by limiting the spill light. In contrast, wider angles (e.g., 120°) broaden coverage of light in open spaces.

Lifespan and Energy Efficiency

This is also a medium involving dimming controls, gentle adjustment from motion structures, and better alarming structures that can reduce or enhance management energy savings according to necessity, such as in the case of industrial, retail, or warehouse facilities.

Highness Analysis

Look for high IP fixture grades to guarantee the safety against dust and water in rugged environments (i.e., IP65 and higher). Furthermore, an aluminum body ensures better heat dissipation, leading to longer LED lighting lives.

Return on Investment (ROI)

As compared to conventional lighting options, the cost of LED high bay lights might appear initially higher, yet you can determine your ROI in detail based on energy savings, lessened maintenance, and an extended life span. Generally, most establishments can record handsome savings amounts in the long run.

By having more to take into serious consideration on these parameters, you will successfully land on just the ideal UFO LED high bay lights for your particular application needs, allowing for a combination of performance and longevity.

Optimal Placement and Layout for High Bay Lighting

The positioning and arrangement of high bay lighting systems play a significant role in sound efficiency while producing effective illumination. Various essential factors would be considered in determining the best arrangement:

Fixture Mounting Point

The high bay lights are installed at a height of 15-40 feet and vary a lot according to the use to which they are going to be put. Higher mounting potentials necessitate luminaries engineered to discharge light while having a sharp, thinned beam. Additionally, the farther apart the mounting position is 15 feet from the ground, the classification of these systems, mainly known as fixtures and supplementary targeting lumens, needs to be highly exceptional.

Lighting Fixture Spacing:

The spacing of the high bay lights must correspond to the height, or else instances of illumination overlapping or under-lighting would predominate. The standard threshold to follow is to have a space equal to 1 to 1.5 times the height from the general-lighting standpoint or 0.5-1 times up from the higher-brightness angle.

Delivery of the Beam Angle is next on the list.

The beam angle dictates the spread of light. Narrow choices, such as 60 degrees, are for higher ceilings with a more focused light output, while wider spreads, around 120 degrees, give greater coverage on lower ceilings.

Purpose and Light Levels

Areas with task-oriented lighting need more light (lumens) for a very specific illumination level. Ensuring that required LED lighting levels are always maintained for great visibility and safety is required for warehouses or factories (300-500 lux recommended for workspaces).

Reflective Surfaces

Light reflects off surfaces like walls and floors, depending on the reflective characteristics. The task of creating optimal uniformity is accomplished with the help of highly reflective and absorbent surfaces, while in other cases, variations demand amendments with respect to fixture configurations or additional lighting.

Lighting Controls

Using motion sensors, dimmers, or daylight harvesting systems, incorporating energy-efficient features while maintaining effective illuminance can keep control over the luminance output for those selected areas where ample daylight is available. The controls should also have provisions for motion and suitable light changes for differing daylight conditions.

For high bay lighting, placement and layout tailored to these factors allow the facility to maximize light uniformity, diminish energy consumption, and fulfill operational lighting requirements.

Choosing the Right High Bay Light Fixture

Selecting the right high bay light fixture requires careful consideration of the following major factors:

Ceiling Height: High bay lights are designed for ceilings 20 feet and above. Make sure the high bay fixture fills the height of the ceiling space with adequate light.

Lumen Output: The required lumen output needs to be paired with your application. Larger or industrial spaces may require more lumens from the fixture.

Energy Efficiency: LED high bay fixtures come in with the highest efficiency in comparison to traditional lighting options, which further reduces costs on energy.

Durability: If operating in conditions that may be contaminated by dust or somewhere where harsh conditions are the order of the day, the best choice would be fixtures made out of tough materials and rated for an IP.

Color Temperature: Choose a color temperature that suits the principal task—higher temperatures (5000K) create more energetic work atmospheres, whereas slightly lower temperatures (4000K) create a warmer ambience.

By evaluating those elements, a facility’s lighting needs can be quickly and effectively addressed while optimizing energy usage and lighting performance.

Key Features to Look for in UFO High Bay Lights

Luminous Efficacy: Lights must have a higher luminous efficacy, typically measured in lumens per watt (lm/W). UFO high bay luminaires should deliver in excess of 140 lm/W while still working at low power levels-maximizing the brightness while minimizing power usage.

Longevity: Look for fixtures with robust housing-often die-cast aluminum-for effective heat dissipation and long-term dependability. Also, go for fixtures rated IP65 or above that resist water and dust, making them suitable for industrial and outdoor applications.

Long Life: A good UFO high bay light ought to last a working life totaling up to 50,000 operating hours. This duration is long, mainly from an economic perspective, wherein maintenance and changes over time are involved in any setting in need of lighting.

Dimmable and Smart Controls: Choose fixtures or light sources with dimmable options and offer the capability of connecting with intelligent devices like occupancy and daylight sensors. These features help in energy-saving purposes and conform to the varying light requirements.

Consistent Distribution of Light: Uniform beam spreads, usually in the range of 90 to 120 degrees, ensure a homogeneous pattern over large areas. By doing this, the main motivating glare is reduced from a visual aspect, thus enhancing safety and performance.

Color Rendering Index (CRI): For spaces where the accuracy of color perception (like a retail unit or manufacturing facility) is required, a very strong CRI is needed, preferably more than 80.

With these technical specifications in mind, one can choose an optimum option from the various UFO high bay lights, as needed by the specific operational considerations of staff as well as simultaneously achieving the objectives of efficiency and long-term functionality.

Comparing Different LED High Bay Fixtures

In comparing LED high by fixtures, it helps immensely to consider several critical variables to hit the perfect fit for your space:

Lumen Output and Efficiency

The lumen output accounts for the light output, while efficiency (lumen per watt) tells of the energy performance. Fixtures above 130 lumens per watt should consume considerably less energy even as they cast the brightest light.

Wattage and Energy Consumption

Appropriate wattage for the desired lumens will give you sufficient brightness while consuming very little energy. For example, 150W LED high-bys can readily replace conventional 400W metal halides and hence save money significantly on electricity.

Type of Mounting Options

Fixtures will always have different mounting options like hooks, brackets, or pendants. However, consideration should be given to fixing those that match up easily with the ceiling height and infrastructure.

Durability and IP Rating

Test their application with an IP rating for outdoor testing to make sure it will stand up to ingress. Light fixtures with an IP65 rating are suitable for waterproof use, particularly in environments where dust might be plentiful, e.g., warehouses, industry.

Angle of Light

Differentiation of intensities within the line of spread is the purpose of the beam angle. Narrow beam angles could be very helpful in places having sizes more than 25 feet when high-intensity illumination is needed and utilized, while wider beam angles are more suited to situations that demand more coverage.

Cost and Warranty

Comparing the initial investment with the long-range output cost. Highest quality products may come at high upfront costs. However, they tend to have longer warranty periods and lower maintenance requirements (5 years or more).

Having looked at the main characteristics across various LED high bay options, an educated decision shall be made regarding which will cater to the facility’s specific needs and also run effectively cost-wise. Further, there are many online outlets that give you more on the product.

Do I Need UFO High Bay Lights for My Space?

I must look at the ceiling height and size of the area that requires light when finding out if UFO high bay lights will fit my space. The best use of these fixtures is where the ceiling height is higher than 15 feet and where bright and uniform light is required to cover large areas. UFO high bay lights are most suitable for practically any lighting need to be met in warehouses, factories, gymnasiums, or large retail facilities, thanks to their efficiency, durability, and superior lighting output. Moreover, the distinction in design is an interesting thing when it comes to compact fixtures, whereas all these advantages make the UFO lights a more viable option. I really need to be concerned with what is specifically required by my space, such as ceiling height, layout, and the required level of lighting.

Reference Sources

Frequently Asked Questions (FAQs)

UFO high bay lights overview: are they, and how is this distinguished from linear high bay lights?

Circular-shaped UFO high bay lights, other words as UFO high or round UFO LED high fixtures, are LED high bay lights in size, suitable for high-ceiling applications. While linear high bay fixtures are long rectangular lights, as to UFO LED lights, they try to focus their light with smaller lumens in a compact, round package of light, while facilitating easier mounting in tight or well-clustered layouts.

Bay lights I need: How do I decide how many UFO LED lights are required for my space?

By figuring out the total lumens needed for the task area and calculating for the ceiling height, foot-candles of light required, and lumens produced by each fixture, an idea as to how many of these fixtures would be needed could be detailed. They are particularly adequate for warehouses and gyms; LED high bays come with lower wattage and more extended life. A lighting expert could help with the layout. Spacing between fixtures would be optimized with the right beam angle to best cover.

UFO high bay lights overview: Can UFO high bay lights be dimmed or controlled for advanced lighting strategies?

Many modern UFO LED fixtures are provided with dimming as well as integration with controls like motion sensors and daylight harvesting. Advanced control options help save energy as low-occupancy periods allow the precision-controlled scene setup to go beyond the baseline savings of fewer wattage fixtures.

Which for-wattage high bay lights can run on a UFO basis? How much maintenance, and what is the expected lifespan of UFO LED high bay lights?

LED high bays, unlike HID systems, are known for having a very long life with as little maintenance involved as ever. They are not fraught with heatsinks and driver options and are truly backwards with drivers and thermal management, allowing for years of reliable operation with minimal attention. Of course, comprehensive cleaning and periodic inspections repair the lumen output and provide for long-term facility lighting applications.