Lighting is one of the most important aspects of the manufacturing process. Where precision, efficiency, and safety are the main concerns, lighting plays a crucial role. Often, traditional lighting systems cannot cope with the strict requirements of these workplaces, and as a result, businesses have to look for more effective alternatives. The solution is UFO high bay lights — a revolutionary technology that can give the required high brightness and energy efficiency to large areas in a factory. But what exactly are the features that make these lights different from others, and what is the reason for manufacturing being the optimal application? This blog will delve into the UFO high bay lighting’s main features, advantages, and uses, thereby making you grasp how this technology can bring a change to the working of your facility. Keep us company as we reveal the secrets of how to light up your area without consuming too much energy and money!

Understanding High Bays

What are High Bay Lights?

High bay lights are the kinds of lamps that are capable of providing a sufficiently bright and even light for areas that have ceilings of 20-40 feet or more. They are primarily used in large areas like warehouses, manufacturing plants, sports halls, and even airplane hangars because of their high output and uniform light distribution. High bay lights, unlike other types of lights, are constructed in such a way that they scatter light across the whole area making it less shadowy and thus more visible. Apart from being energy-efficient, such fixtures also have a robust design, which is why they are widely preferred by commercial and industrial setups.

Varieties of High Bay Lights

High bay lights consist of different kinds of lights, which are best suited for those particular needs and environments. Based on the current search trends and industry analysis, here are the most commonly found types:

LED High Bay Lights

LED high bay lights have emerged as the first among equals because of their unmatched energy efficiency, long life, and great quality of light. They not only produce vibrant, even light but also at the same time consume much less power than the conventional lighting options. What’s more, LEDs emit very little heat so that the cooling costs for the big facilities can also be reduced.

Fluorescent High Bay Lights

Fluorescent high bay lights are known as the more affordable option for commercial and industrial establishments. They do not attract a large share of the energy-saving pie in comparison to their more advanced counterparts but do create the energy-saving environment when used along with older technologies. The life span and running as well as efficiency of fluorescent lights are usually lower than that of LEDs. Therefore, the question of maintenance arises since the fluorescent bulbs need to be replaced much more frequently.

HID High Bay Lights (High-Intensity Discharge)

HID lights, including metal halide and high-pressure sodium, have long been the industry standard for lighting. They provide an excellent level of brightness while consuming a lot of electricity and taking a longer time to start. These elements are causing today’s modern factories to gradually switch over to LED’s.

Induction High Bay Lights

Induction lighting does not depend on electrodes or filaments and therefore can boast a long lifetime and stable performance. Although their usage is not as widespread as that of LEDs, they can still be considered as a good option for projects where extreme conditions and durability are concerned, especially when there is no possibility of regular maintenance.

Reflector-Based High Bay Lights

The reflector-based high bay systems use reflectors to steer and amplify the light in particular spots, making the lighting more intense for precise tasks. They are ideal for the areas where concentrated lighting is required, like when pushing assembling lines, workshops, etc.

By knowing the classes of lights and their respective applications, companies can pick the optimal high bay lighting system that not only saves energy but also keeps up with the cost and offers a good illuminated environment for their building.

Advantages of High Bay Lights

High bay lights come with various advantages including the provision of safety and comfort lighting that provides light to the whole area of attention. The latter directly helps in accident prevention and improves people’s output; the same way it limits the consumption of electricity and hence operational costs when pigments are used because of their power efficiency. Moreover, they are durable with minimal maintenance requirements which lead to their being a long-term economical solution. Besides, they come in many different designs and wattage ranges making it easy for one to choose the most appropriate depending on the application – focused lighting for workstations or indoor diffuse for general lighting days. Therefore, the businesses selecting high bay fittings get not only the best in lighting performance but also the opportunity to lessen their carbon footprint.

LED High Bay Lighting Solutions

Advantages of LED High Bay Lights

The advantages of LED high bay lights are many and that is why the demand for them is quite substantial in the industrial and commercial sector. The major advantage is their energy efficiency which is remarkably high as they consume much lower power than traditional lighting systems while giving brighter and more even illumination at the same time. A significant reduction of the need for replacement and maintenance costs is achieved through the longer lifespan of LED high bay lights, thus less frequent operation interruptions caused by this. Their ability to withstand tough environments is another feature that comes along with their reliability. They also cut down on energy and carbon emissions which is a nice gesture towards eco-friendliness and are thus in line with environmentally aware practices. The versatility of these lights can be demonstrated by their ability to handle different types of lighting demands, since they can be used for bright lighting on a specific workstation or for the lighting of the whole area.

Comparison of LED high bay lights with traditional lighting

LED high bay lighting has won the battle against traditional lighting by giving undeniable benefits. Traditional lights like fluorescent and metal halide still have some customers but nonetheless, LED HIGH BAYS are over them. Lighting, LED HIGH BAY are consuming only a small amount of energy compared to neon lights and still delivering the same amount or even more brightness. This energy efficiency not only positively impacts on the monthly electric bill but also on the environment as it leads to fewer power plants and less fuel consumption. In sharp contrast to incandescent, traditional lights, and types of modern LED lamps, LEDs use the least amount of electricity, which means they are non-invasive in terms of maintenance. Besides, one does not have to wait for the lights to turn on as it is instant illumination, nor will there be issues with light flickering and dimming as these are very consistent. In addition, superior heat dissipation along with being mercury-free and non-toxic makes them even safer and greener. It should not come as a surprise then that their combined qualities put LED high bays at the top of the list of lighting demands for the future.

Deciding on the Ideal LED High Bay Fixture

To choose the right LED high bay fixture, you have to take into account a number of very important aspects that will guarantee both the performance and efficiency to the fullest. To begin with, you have to consider the dimensions and height of the area in order to get a clue about the right wattage and lumen output that will be required for sufficient lighting. Then comes the beam angle evaluation which is very important since it determines the footprint of the light coming out of the fixture, making it either narrow if the light needs to be focused or wide if the area has to be covered. You might also want to consider these additional features: dimmability, motion sensors, and color temperature options as they are some things that can greatly enhance energy efficiency and let you set the light according to your specific requirements. Finally, do not compromise on durability and quality; instead, go for fixtures made with strong materials and that have been certified for safety and performance. This way you are sure the fixtures will not be the first things to go in your industrial or commercial environment.

Applications in Manufacturing Facilities

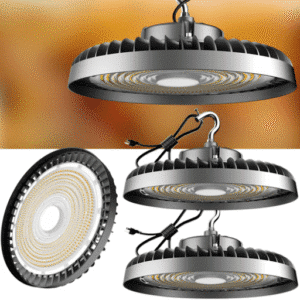

Optimal Use of UFO High Bay Lights

UFO high bay lights are the perfect solution for manufacturing facilities where there are high ceilings and wide floor areas and that include production floors, assembly lines, and storage warehouses. They create an even light distribution thanks to their circular design which also reduces the shadows and increases the visibility for the precision work and safety of the workers. These lights must be placed at specific points so that they cover the important zones with light, and that they provide light which is sufficient without overlapping or having dark spots. The choice of fixtures with dimming features or motion sensors can play a significant role in optimizing electricity use during the hours when the use is low. Moreover, the use of high-quality materials as well as fittings that have safety certifications will guarantee long-lasting performance even in demanding environments characterized by heat, dust, or vibrations.

Warehouse Lighting Requirements

It is a good idea to sync with the latest data and industry trends when planning warehouse lighting as this will make the lighting system not only functional but also compliant with the modern standards. Based on search engine data, there has been an increase in search queries for “energy-efficient warehouse lights” and “LED lighting solutions for warehouses”, which shows that more and more people are interested in sustainable lighting options. LED fixtures still have the upper hand for they are energy-efficient and have a long life span which results in lower maintenance costs. Not only that, but smart lighting systems compatible with IoT technology are also considered to be a ‘must’ for warehouses that want to reduce their energy consumption and increase their overall efficiency.

Compliance with the safety of workers and the standards set for safety is another major issue, which calls for the application of the Illuminating Engineering Society (IES) guidelines. It is very important to maintain the required lux levels in different zones, such as storage areas, loading docks, and workstations. For example, areas requiring detailed work may need higher lux levels (over 500 lux) while general storage areas may operate comfortably at lower levels (200-300 lux). Furthermore, the adoption of data-driven strategies like light mapping and energy analysis guarantees that lighting systems are located and customized according to warehouse layouts, thus maximizing efficiency and security.

Sensor Integration for High Bay Lighting

The addition of sensors to high bay lighting systems in warehouses is a major factor that spells out improved operational capacity and energy savings. For instance, motion sensors can pick up movements and change the light levels so that only the area being occupied gets lit up. Daylight sensors do the opposite, they keep track of how much light is coming from the sun and controlling the artificial light so that there is always the same amount of light while cutting down on the use of energy that is not really needed. Advanced systems can even have IoT-enabled sensors that give continuous performance data, leading to predictive maintenance which in turn optimizes energy use even more. By using these technologies strategically, warehouses can not only improve safety but also lower costs and have more control over their lighting systems.

Installation and Maintenance

Installation Tips for High Bay Lights

The method used in the installation of high bay lights is very crucial and it entails carrying out very thorough lighting assessment of the particular area requirements, i.e., ceiling height, floor layout, and the amount of light required. If you are going to mount the lights in the air or on the surface, it is necessary to use the right tools and mounting hardware for a safe and secure attachment. The correct location and spacing of the lights are very important in order to avoid dark areas or uneven lighting. Check that the lights are compatible with the present power supplies and that all wiring is done right to avoid any faults. If you wish to, consider using dimmer switches or motion sensors as part of the installation to increase the efficiency of lighting. Always adhere to the manufacturer’s guidelines and local wiring regulations for safety and performance.

Maintenance Best Practices

Constant maintenance of lighting systems is vital to their long life and performance. First, regularly inspect all fixtures for any signs of wear, damage, or loose connections, and deal with problems quickly to stop them from getting worse. Clean lenses and bulbs regularly to remove dust or dirt that can lower brightness or affect beam quality. Test dimmer switches, motion sensors, and other integrated parts to make sure they are working properly. Change burnt-out or flickering bulbs only with similar ones to keep the light level and energy use constant. Follow manufacturers’ maintenance guides and ensure that the repairs comply with local regulations so that your system is safe and dependable.

Common Issues and Troubleshooting

In the process of troubleshooting the main lighting malfunctions, one should not just react to the symptoms but one should try to find the root cause of the problem in a systematic way. Here are some common problems:

Flickering Lights

Flickering lights may have a loose bulb connection, bad wiring, or a dimmer switch that does not match the light. The first thing to do is to ensure that the bulb is fitting tightly and it is suitable for the fixture. Then, if needed, inspect the wiring or connect a proper dimmer. If the flickering is widespread, check the voltage stability in your electrical system.

Lights Not Turning On

The reason for a light not turning on could be because the bulb is burnt out, the circuit breaker has tripped, or the switch is defective. First, replace the bulb and reset the breaker, and lastly, test the switch to see if it works. In case the three steps do not fix the problem, call an electrician to look for deeper electrical faults.

Dim Lighting Output

Dim lighting even with the right bulbs is often due to the dirty fixtures, old bulbs, or a drop in voltage. Start the troubleshooting process by cleaning the fixture to eliminate dust and dirt buildups. If the problem continues, test the voltage supply or consider switching to high-lumen bulbs that are within the wattage tolerance of the fixture.

Motion Sensors Not Working Properly

Poorly aligned or obstructed sensors can result in faulty operation of motion lights. Inspect the sensor position and make sure it is unobstructed and clean. Change sensitivity settings and check if the timer is set correctly. If the failure goes on, replacing the sensor might be necessary.

Buzzing or Humming Sounds

Buzzing usually means a bulb that is not proper for the fixture or a problem with the electrical current. Switching to high-quality LED and one that is designed for silent operation or replacing old ballasts can go a long way in eliminating disturbances.

Warehouse Lighting Solutions with High Bay LEDs

Advantages of High Bay LED Lighting in Warehouses

LED high bay lighting offers a number of benefits in a warehouse setting, enhancing functionality and cost-effectiveness. Such lighting sources give off bright and uniform illumination, which is extremely important for the large areas having high ceilings where it is crucial to have visuality and minimize mistakes at the workplace. In comparison to conventional lighting, HighBay LEDs are great at energy saving: they draw power on a relatively low compute scale, thus translating into lower energy bills. These longevity-oriented High Bay LEDs decrease the need to make replacements over the years and are less of a hindrance in maintenance and illumination operations. Instant-on operation means lights go on right away, unlike most traditional types of lighting, which require some warm-up time, making for increase in productivity as an attribute. Additionally, the fixtures create nearly no heat output, providing a much safer and more comfortable workplace environment for all workers. High Bay LED lighting adds large benefits to a modern warehouse that wants to sustain its operations effectively while reducing ongoing costs.

Designing an Effective Lighting Layout

When designing an effective lighting layout, it should ensure even light distribution while minimizing the existence of shadowed spots. The onset clearly involves scrutinizing the facility layout. This should involve air volume or ceiling height, shelf type and configuration, work zone dynamics, denoting liberally near-perfect luminaire placement. Through the use of photometric planning tools, one can produce depictions of the light use values and spacing required to ensure the lack of fluctuations in terms of lighting levels. An additional point is in maximizing the decision that primarily centers on remaining energy efficient in all aspects by the choice of the LED light fixtures such as operating in duo with motion detectors or dimming controls. And this helps in both increasing visibility, requiring safety, and therefore reducing power consumption and operational costs.

References

-

Senior Thesis Final Report

Link to source

This report discusses high bay fluorescent luminaires and their applications in gymnasium spaces. -

Electrical Energy Equipment: Lighting

Link to source

This document provides insights into lighting equipment and utilization factors from manufacturers. -

High-Intensity Discharge Industrial Lighting Design Strategies

Link to source

This paper explores lighting design techniques and luminaire layout algorithms for industrial applications.

Frequently Asked Questions (FAQ)

What should I be thinking about when choosing lighting for high ceiling environments?

Ideal LED high bay lighting fixtures serve these spaces, which have high ceilings. Such luminous LEDs, which boast the correct lumen outputs and beam angles will light spacious indoor environments with ailing mounting heights without creating any dark areas. While considering the lowest Lumen per watt manoeuvrability possible to lower the energy costs while still providing the necessary foot candle level, expensive high bay LED lights may have optional controls or dimming for occupancy and daylight adaptation. Industrial LED high bay lights are more likely to be proficient in sophisticated thermal management and construction for factory use. Should an assessment reveal that the existing fixtures and mounting heights are not perfectly suited to one another, retrofit kits may be anticipate with high bay lighting fixtures. Terms: thus far unused: energy costs, fixtures deliver, existing fixture.

How about led linear high bay fixtures in retail stores and shop lights?

Linear-type high bay fixtures are optimal lighting solutions given the cases like shops, led high bay retail-LED linear fixtures perform higher-level illumination to provide a specific illumination across a balance range without any glaring effect. The optical lighting in the past was a fluorescent light system with a high maintenance order thus necessitating higher energy loads of a store and other commercial settings, and the linear LED solution sets high standards for any retail environment with adjustable CCT and property. In stores or commercial spaces with a high ceiling, linear high bay lighting could streamline light distribution off aisles and alongside exhibits. LED high bay linear fixtures are best-suited to serve any low-energy circumstances. Shop led high bay commercial and industry cct all of these concerns should be included as redundant terms.

Which types of high bay luminaires are commonly available and how should I go about choosing one?

LED high bay lights come in three main types: linear, round (commonly known as UFO type) bay lights, and modular high bay lights that cater to specific beam control and mounting type requirements. Solar irradiator for low awoman. To find the right type consider the inherent ceiling height, the level of light required, the range of beam angle, lumens per watt, and general industrial or commercial purpose such as warehouse use, factory floors, or retail applications. Consider energy costs, how often you want to change to keep them shining on, and if you need them to work selectable or dimmable for easy interconnection to building controls. Various types of fixtures provide luminous distributions and forms. One potential strategy is often mixed luminous distributions in diverse forms to light up big indoor spaces. Unused items: lumens per watt, energy costs, commercial lighting.

Why is a linear high bay and where is it best used right now?

A linear high bay is an elongated LED linear light fixture designed to illuminate large indoor spaces with high ceilings such as warehouses, retail stores, and factory floors. These led linear high bay fixtures deliver uniform lighting across aisles and work zones, making them ideal for commercial and industrial settings that require powerful lighting and efficient lighting to reduce energy costs. Many of our linear high bay led lights offer selectable CCT and wattage options to tailor lumens per watt and light distribution to the task. Fixtures provide flexible mounting and are often preferred over UFO styles when continuous row lighting and reduced glare are important. Suggested unused terms: selectable, cct, lumens per watt.

What is the feature of the round high bay that differentiates it from linear designs?

Sleek UFO LED high bay lights aim to project light in a round manner and are often best suited for high-ceiling applications such as warehouse lights, gyms, or manufacturing floors. UFOs give excellent lumen to wattage output and are often diminutive compared to the linear high bay lights, thus making them more suitable for high racking and locales where point-source lighting is desired. Be able to design industrial LED fixtures higher in round with appropriate ranges of CCT and beam angles for brightness and luminance balance. In many scenarios, both UFO high bay lights and linear fixtures will provide better flexibility for well-mixed lighting-to-task and general illumination systems. Keyphrase: UFO LED high bay, gym lighting, LED round high.