Upgrading to energy-efficient lights in your business or factory could appear to be a significant expense; however, determining when it starts paying might actually be quite challenging. Enter the LED High Bay ROI Calculator, a tool designed to calculate just that by assessing how financial benefits would relate to upgrading to LED high bay lighting. It will not only provide a fair idea, but it will also spell out the time frame in which you begin recovering your investment. Whether it’s about cutting operation costs, reducing power bills, or having some degree of concern for our environment, a precursory study into and comprehension of the break-even point becomes undoubtedly crucial. In this blog post, we will elaborate on some specifics that will certainly help you to understand better the significance of ROI calculations and the way this powerful tool can be a genuine propeller in making the correct business decisions. Keep reading to learn how soon you can begin to reap the benefits of your illumination upgrade!

Understanding High Bay Lighting

What is High Bay Lighting?

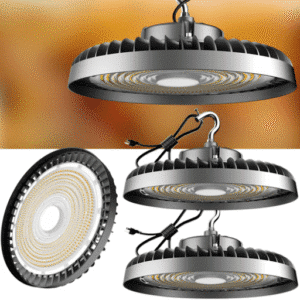

High bay lights are specially designed luminaires for those spaces having overly long heights and are usually 20 feet plus. Commonly used in large, indoor areas such as warehouses, manufacturing facilities, gymnasiums, and retail stores, these lights give bright, uniformly spread illumination over the space. The high bay lighting fixture is an ultra-efficient aesthetic and light distribution solution for long periods of prolonged usage.

Types of High Bay Fixtures

High bay fixtures are made in different styles and designs to suit several applications and requirements. Here are the typical types:

LED High Bay Lights

LED lights are the most efficient and long-lasting lighting solution available, providing bright light that is consistent and uniform. It ensures a low maintenance light source with significantly less energy consumption compared to traditional lighting options. Indeed, LEDs are environmentally sound, offering a multi-functional upgrade for modern business places as well as reduction in the costs of operations.

Metal Halide High-Intensity Discharge (HID) Fixtures

Metal halide high-bay lights obtain a white form of light that has been widely used in HID-based lighting fixtures for many years globally. However, these fixtures use a lot more energy and have very short lifespans compared to LEDs.

Fluorescent High-Intensity Discharge Fixtures

Fluorescent fixtures are mostly compact and can cast out light very natural to the environment and easily accessible on the market. Their main focus is also cost while efficiently providing adequate light for indoor use. Although they are more efficient than metal halide lamps, they still lose much of the advantages of LED lights.

High-Pressure Sodium (HPS) and Induction Lamps

Induction lamps maintain a lengthy lifespan without reducing light quality. Conversely to LEDs, induction lamps are power converters where magnetic fields are inducted; there are no filaments or electrodes that need to be heated.

Benefits of LED High Bay Lighting

LED high bay lights have a variety of benefits that make them an ideal option for commercial and industrial facilities:

⚡ Energy Efficiency

LED high bay lights consume only a quarter or less of the energy consumed by traditional lighting options, resulting in substantial savings for facilities over time.

⏱️ Extended Lifespan

LED bulbs boast a lifespan that is well over 50,000 hours, thereby reducing maintenance needs and replacement costs significantly.

🌍 Environmental Safety

There are no mercury or other hazardous materials in LED lights and far less heat is emitted, making them environmentally friendly.

💡 Superior Light Quality

These lights provide smooth and consistent light with minimum flicker, ensuring reduced work-related incidents in warehouses, gyms, and factories.

🔌 Smart Technology Integration

With modern smart technology, LED high bay lighting can have motion sensors and dimming control or be linked with IoT systems that will edge closer to automation and more environmentally sound energy efficiency. According to statistics from the recent past, growing adoption of LEDs is on the steep climb, thanks to the worldwide push for sustainable efforts and cost-efficient solutions. This positioning suggests that LED high bay lights may be an investment fit for our present-day economic and environmental concerns.

Calculating ROI for LED High Bay Lights

What is ROI?

Return on Investment (ROI) is a key performance metric used to evaluate the profitability of an investment. The ROI is the net benefit or savings generated by an investment divided by its initial cost, multiplied by 100 to express the result as a percentage. For LED high bay lights, the ROI helps calculate how fast energy savings, decreased maintenance costs, and various benefits will render the upfront cost irrelevant, by providing the real financial benefits of the investment.

Components of ROI Calculation

💡 Pro Tip: A company should utilize all these key elements to thoroughly examine returns on investment from the perspective of upgrading to LED high bay lights for the most accurate financial projections.

Cost Savings from Switching to LED High Bay Fixtures

Initial Investment vs. Long-Term Savings

Switching to LED high bay requires a greater initial investment, but the yield is significantly higher. By keeping their operational efficiency, these fixtures consume less power, thus leading to less electricity spent annually. Ultimately, less electricity billed means good savings for flourishing businesses. Additionally, these fixtures offer a long life that further slashes the cycle on maintenance or replacement costs. In short, the three layers of savings tip the scale favorably on investment payback time. This is why the new LEDs offer financial viability for business operators who wish to see value for their money, with less energy consumption, excellent quality lighting, and optimal operational and maintenance costs.

Maintenance Associated Costs

LED lighting significantly reduces maintenance costs compared to traditional lighting systems. With an extended lifespan of up to 50,000 hours or more, this means there is less frequent replacement and therefore reduced labor costs for maintenance staff. Furthermore, they are less easily broken and apt to fail due to vibrations or environmental factors, thus reducing the need for repair. Together, all these factors render LEDs as a cost-effective solution for installation in commercial and industrial settings where maintenance can be labor-intensive and expensive.

Energy Efficiency and Cost Savings

⚡ Key Energy Statistics

LED lighting, marketed as the most energy efficacious of lights, is in fact just that. Recent study results report that LED lighting consumes up to 75% less energy in comparison to traditional incandescent bulbs, altogether resulting in significantly reduced electrical bills. Additionally, their efficiency has kept improving with further advancements, giving the possibilities of greatly reducing energy bills with practically no damage to the environment. It is therefore clear that these two benefits of LED lights have merged into their being indispensable in today’s renewable energy marketplace.

Choosing the Right LED High Bay Fixtures

Factors to Consider: Lumen Output and CRI

When selecting LED high bay fixtures, it is essential to consider both lumen output and Color Rendering Index (CRI) in order to ensure optimal performance and illumination. Lumen output defines the light levels for best illumination that should be in direct alignment with the specific lighting needs of the space—higher ceilings or larger areas will likely necessitate higher lumen levels. However, the measuring of the CRI of a fixture is a bit different, showing the ability of the fixture to accurately render colors as compared to natural light; higher CRI values indicate better color accuracy. Thus, for spaces such as warehouses or retail floors where visibility and color accuracy are both of paramount importance, a fixture with proper lumens and a high CRI of 80 or above must be selected.

📊 Lumen Output

Defines light levels and brightness. Higher ceilings and larger areas require higher lumen levels for adequate illumination.

🎨 Color Rendering Index (CRI)

Measures color accuracy compared to natural light. CRI of 80+ is recommended for optimal color representation.

Color Temperature and Brightness

The color temperature and brightness play a significant role in creating ambience and functionality in a space. Color temperature determines the mood and perception of a place. While the warmer tones (2700K-3000K) create an intimate and welcoming atmosphere, preferred often in residential spaces, the cooler tones (4000K-5000K) maintain focus and energy and thus are preferred often within office and commercial settings. Brightness in lumens is, of course, a critical function in visibility and livability—ensuring that there is adequate light to work with without adverse side effects of discomfort or glare. The capacity to pick the appropriate combination of color temperature and brightness will enhance performance based on the demand of their particular applications concerning an optimal contribution to performance and comfort.

Selecting Warehouse High Bay Solutions

While choosing the most suitable high bay lighting for the warehouse, the facility manager needs to precisely judge their specific needs:

- Ceiling Height and Room Size: Determine the height of the ceilings as well as the size of the room. These are determining factors for what kind of fixtures will fit and where.

- Light Color Selection: Choose the best light color to match with the mood you are trying to create. Warmer tones create a cozy and comfortable atmosphere, while cooler tones enhance focus and visibility in task-oriented areas.

- Lumen Rating: The lumen rating for the fixtures should be satisfactory to light the entire area without causing any glare or shadows, which might hinder productivity or safety.

- Energy-Efficient LED Options: Try to get the energy-efficient LED option whenever possible. This is the best way to achieve economy due to lower electricity bills, extended lifespan, and uniform performance throughout, especially in demanding environments where traditional lighting could let you down.

References

-

University of Montana – Energy Conservation Strategies

This source discusses the replacement of high bay luminaires with high-efficiency LEDs and their energy-saving benefits.

Read more here -

City of Wilmington – Energy and Waste Reduction Update

This document highlights the benefits of replacing high bay fluorescent lights with LED lighting, including improved lighting quality and reduced energy costs.

Read more here -

Andrews University – LED High Bay ROI

This source emphasizes the quick return on investment (ROI) achieved through energy savings and reduced CO2 emissions with LED lighting systems.

Read more here