Without a doubt, proper lighting is crucial when it comes to the safety, productivity, and energy aspects of a place, more so in the huge industrial and commercial areas. You can provide a maximum amount of light with high bay lights specially made for high ceilings. However, where they work best heavily depends on the strategic placement of the lights. Are you one of those who wonder how to have just the right amount of light and keep it even throughout your area? This tutorial will be your go-to when it comes to figuring out high bay light spacing, as it helps you create an appropriate lighting layout that is perfect for your requirements. Whether you are setting up a warehouse, gymnasium, or manufacturing plant, it is a worthy effort to know the light spacing rules as they can substantially improve the space and also make it user-friendly through this light and efficiency factor.

Understanding High Bay Lights

What are High Bay Lights?

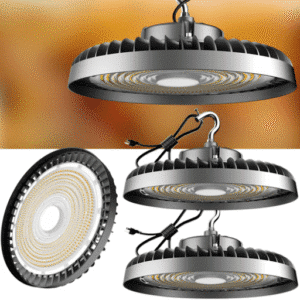

High bay lights are a type of lighting product that are especially powerful, and they make spaces with tall ceilings brighter, like those that usually have heights reading from 15 to 40 feet. They are most often found in huge indoor spaces such as warehouses, factories, gym, and retail store. They provide strong and at the same time, uniform lighting at considerable distances, which is why they are the perfect choice for places where the lighting must be just excellent and in such a way that safe working conditions are ensured as well. High bay lights can be of various designs such as LED, metal halide, and compact fluorescent lamps with each one of them having its own energy efficiency, reliability, and performance.

Types of High Bay Lights

Different types of high bay light fixtures are provided to use in particular cases. LED high bay lights are environmentally and economically friendly, lasting for a long time and having a powerful and bright light source which will also allow you to save money by reducing energy costs. Fluorescent high bay lights give customers a cost-effective option as well as a good-quality light source and a relatively low first cost; on the other hand, they result in a lower life cycle compared to LEDs. Metal halide high bay lights are among the world’s most powerful lights that are perfect for all spaces but which are power-intensive as well as maintenance-intensive. To select the correct type, you need to consider factors such as energy efficiency, cost, lifetime, and the exact lighting requirements of the area.

Benefits of Using LED High Bay Lighting

LED high bay lighting definitely to highlight the term as it provides significantly better solutions, and this situation has led to its being a favorite in most of the areas. They are very power-efficient as the lights consume much less power as compared to traditional lighting sources such as metal halide or even fluorescent ones (this results in a lower energy bill). Moreover, their long life contributes to lowering maintenance and replacement costs on a larger scale. By installing LEDs, one can get good light quality, steady brightness, and no or negligible flickering patterns that can lead to a very good level of visibility in huge spaces. LEDs are also eco-friendly, zero hazardous materials, and low heat output (which could mean an overall safer working environment with the condition being a workplace). Such combined advantages make LED high bay lighting the most practical option for lighting up areas efficiently, cost-effectively or at least in a sustainable way in different fields.

Determining the Right Number of High Bay Lights

Factors Influencing the Number of High Bay Lights

A variety of aspects might influence the determination of the number of high bay lights necessary in a certain location. Dimensions of the area and also the height if we talk about the most proximate cause that determines the light’s spread and intensity. The space’s function or the set of functions it offers is another important factor to be taken into consideration. They are known because the lighting requirements are in foot candles or lux, activities at different times do not require the same levels of illumination. Warehouses are examples of spaces that can possibly require less light compared to the light that might be needed in the assembly areas where very precise work is required.

In addition, the reflectivity of walls and ceilings should be taken into account; because dark colors, black colors, in particular, reflect the least light and thus may need more light levels to be achieved by the fixtures in that area, which can lead to additional energy consumption. High bay lights of various types and wattages also make a difference as the ones with higher lumens or with a better energy efficiency can decrease the need for the total amount of the fixtures. A combination of all these factors means that the lighting layout is to be both fruitful and energy-saving. By using the most recent data and making it the foundation of your calculations in an online lighting layout utility or by contacting lighting specialists, you will be able to identify the best setup for a high bay lighting system in your particular location.

Working through an interactive LED high bay lighting calculator

When you use an LED high bay light calculator, you will have an easier time finding out what is the best arrangement for your lighting. You just need to key in the measures of the location, the height at which the fixture is going to be installed, the desired amount of light (as measured in lumens), and the way the space will be used, and there you have a personalized recommendation. Nevertheless, the algorithm takes into account the losing power LED lamps have, required distance between luminaires so as to avoid over-lighting, and other factors which result in recommending the right number of fixtures and their placing. This can lead to quicker decisions and the eventual outcome is going to be an energy-saving light that fits your lighting needs perfectly.

Common Mistakes in High Bay Light Calculation

- The Mounting Height is Not Correct: If the height of the light is not considered properly, one of the problems that might result is non-uniform distribution of light in the space or poor lighting because the coverage is not adequate.

- Spacing Requirements Are Not Taken Seriously: Many of the light units are not spread out well enough, there are chances of having shadows or areas which are too bright and therefore, the light provided is not effective.

- If the Lumen Requirements are Ignored: Failure to assess the light intensity necessary for the space may cause either too dim lighting or unnecessarily high power consumption.

- Reflectance Factors are not Taken into account: The lack of attention towards the wall and ceiling reflectance can affect both the light levels and the effectiveness.

- Energy Efficiency is not a Priority: Not taking into account energy-efficient fixtures when deciding is likely to result in escalating operating costs in the long run.

By not making these errors, you can be guaranteed of both the best performance and energy efficiency in your high bay lighting system.

Optimal High Bay Light Layout

High Bay Lighting Design Principles

When it comes to the design of high bay lighting, a number of principles need to be followed in order to get the most efficient and effective illumination. The foremost thing to do is for the evaluator to make his choice based on where and how high in the ceiling the fixtures are going to be mounted and at the same time, be able to achieve a uniform light distribution with no or very little overlapping or shadowing. Fixtures with the right beam angles for the application should be chosen so that there is a minimal loss of light and most of it reaches the target area, which is effectively done by picking the kinds of headlights that are up to the job. Also, the reflectance of walls and ceilings, for instance, can go a long way in terms of the total lighting output of a location; therefore, it is necessary to take this into account. The list of the benefits of this approach goes on and on. The most crucial among them, however, is that energy-efficient lighting sources, like LED, save money through a reduced energy bill, and besides, they can provide higher levels of brightness than the less-efficient types of fixtures can. A smart lighting design choice will give you a healthy and money-saving environment by sticking to the above-mentioned practices, even though some might argue that the initial setup cost is high.

Effective Lighting Layout for Warehouses

When figuring out what the best lighting layout for factories and storages, do not forget such things as how towering the ceiling is, what racking systems are installed, and what the tasks are done in the area. In the case of super high ceilings, it is always a good idea to use high bay light fixtures and make the light to be as even as possible so no light and dark areas are created. Your fixtures will have to be placed so they can effectively fill the room with light but this will depend on obstacles such as shelving and equipment. Save energy by using LEDs, the most efficient light source available on the market. Add sensors that can sense movement or devices that control over the amount of sunlight to be used in the lighting system when there is enough external sunshine is available. By applying proper techniques and following the laws for creating a suitable lighting design which will improve the overall functions of an organization you will reach the goal of a warehouse which is not only a highly visible and safe to work in but also the one that is going to save energy.

Spacing Considerations for High Bay Fixtures

Spacing the high bay fixtures properly is very crucial to the process of ensuring a consistent and good light all over the area. The distance of one fixture to another should be the result of the height of the ceiling’s model and the light distribution the fixtures present. In general, the distance of the luminaires from the ground for mounting purposes ranges from 1 to 1.5 times the installation height for general lighting stabilization. Nevertheless, for tasks with a main source of light, the distance should be reduced even more. Besides this, to lessen the presence of shadows another thing to consider is to avoid the light beams of the bulbs overlapping each other and the presence of obstacles like closed-shelving units and machines. Finally, one can get optimal fixture spacing and uniformity through simulating the lighting and consulting the layout guidelines.

High Bay Light Spacing Techniques

Calculating Distance Between High Bay Lights

In order to calculate the fixtures’ separation, the most relevant factors are mounting height and the required luminous uniformity. As a general rule, when the lighting uniformity is just conformed to standard, the light fixtures should be mounted at spaces equal to 1 to 1.5 times their mounting heights. For example, a luminaires that are mounted around 20 feet above the floor should be placed at intervals ranging from 20 to 30 feet. For tasks requiring higher precision and focused illumination, the spacing is then reduced to less than 1 times the mounting height. Beaming angle, fixture type, and area layout are also part of the mix. Applying thorough tests in illumination analysis may further clarify the layout to not compromise on brightness or create considerable shadows as a consequence.

Fixtures Spacing Suggestions

Efficient and uniformly lighting is achieved through the correct values of spacing at light fixtures; usually, for general illumination, it is about 1 to 1.5 times the height of mounting of the light fixtures; for instance: for an installation at 20 feet above the floor, the distance between them should be in the range of 20 to 30 feet. However, for the work that needs higher precision and focused light, the distance should be lesser than the mounting height in order to give these qualities. Consider the fixture type, beam angle, and area layout, for example, among other important considerations that lead to great results for application. Thus, a lighting simulation or some other form of analysis at a particular point in design would even further fine-tune these aspects to minimize shadows and ensure consistent light.

High Bay Light Distributions

The high bay light distribution pattern is planned for serving various lighting necessities and closely aligned with the lay of the space. The most popular distribution patterns consist of narrow, medium, and wide beam angles. Narrow beam angles are usually intended for high ceilings, allowing concentrated light targeting a smaller area; medium beam angles are more to use with moderate beam spread for general lighting for midsize spaces. Wide beam angles are, hereby, best for low mounting heights or uniform coverage over a broad area, assuring adequate illumination. Several criteria that feed into the selection of a specific distribution pattern include mounting height, space size, and function-specific needs and lumen requirements. Herein, it is highly dependent on the design of the setup and results in the cut downs of shadows while promoting maximum energy. With fulfilling the lighting demands for a specific job, all these requirements can contribute towards generating a well-lit and functional environment.

Final Considerations for High Bay Lighting

Evaluating Light Quality and Distribution

Lighting conditions and layout, in case of high/ low ceiling industrial lighting, should be assessed from the perspectives of color temperature, CRI, and uniformity. Recent studies suggest a most common selection of 4000K to 5000K color temperature that tends to offer a mild bright white, most suitable for warehouses and factories and other high ceiling applications. A high CRI makes sure that visibility is good, rendering colors accurately, which is crucial for precision tasks.

The specialization of distribution pattern ought to follow the particular task that the area will be accommodating; lights giving a narrow beam angle can be utilized in very directed installations, such as in high ceilings, around 30 to 40 feet, so that they can project into a smaller section as opposed to providing a more diffused light-source into a larger space. On the other hand, one would like broader beams for a more evenly distributed light when mounting at lower heights. When appropriate fixtures are added and LED technology, which revolves on state-of-the-art equipment, is engineered to maximize energy efficiency, the required intensity of light needs to be exercised without creating shadows, therefore guaranteeing a safe and energystar application.

Maintenance for High Bay Light Fixtures

For high bay lighting fixtures, maintenance is necessary to ensure their longevity and peak performance. This involves performing routine inspections of fixtures, looking for dust, debris, or other messes that might settle and lower light output. Cleaning of the glass lenses and housing is needed every so often with an approved, soft, non-abrasive rag and a cleaning solution. Any loose connections, damaged wiring, or wear and tear should be taken into account with any mounting hardware. Replacement of any part with a defect will save the lighting fixture for other problems in the future.

Leveraging today’s technology on advanced LED technology, any high bay fixtures have become less troublesome than the earlier fixtures. The use of low-power LEDs extends bulb life and less chance of unexpected failures. Smart lighting control is seen as one avenue that has made sense with this system of further automated routine fixture performance control, to give real-time alerts when maintenance is required. Paired with active maintenance operations, these latest features make an environmentally friendly lighting system for every application.

Key Takeaways

- High bay lights are designed for spaces with ceilings ranging from 15 to 40 feet

- LED high bay lights offer superior energy efficiency and longevity

- Proper spacing typically ranges from 1 to 1.5 times the mounting height

- Factors like ceiling height, beam angle, and space function influence fixture placement

- Regular maintenance ensures optimal performance and extended fixture life

References

-

Senior Thesis Final Report

Link to source

This report discusses lighting design and placement in industrial and commercial spaces, including high bay lighting. -

Design Guidelines

Link to source

A comprehensive guide from Illinois State University covering design and placement guidelines for lighting and other facilities. -

National Best Practices Manual for Building High Performance Schools

Link to source

Frequently Asked Questions (FAQ)

What kind of fixtures and which spacing should I consider creating?

The type of high bay lights you need to choose depends on, along with your space size, the amount of light you need, and all the relevant high bay light fixture recommendations on spacing. The lighting guide or a lighting design software could now help in estimating the number of high bay lights one might need and if the option for either linear high bay lights or ufo high bay fixtures should be used. In an industrial-type lighting layout, a high lumen output and greater space between fixtures are unexpectedly being predicted to minimizes the number of led high bays required. Inquire with a lighting designer or use free lighting layout tools to model the light’s beam angle and figure out its spread of light over the working plane. Mention sparingly: lighting planning, high bay led lights, high bay lighting to bring about, spacing to guarantee.

Can I use a higher count of LED high bay lights for broader coverage?

Suppose many LED high bay lights would help in the uniformity; they may fall short of being very efficient if they do carry low output and fail to focus the lights in the brighter surface; higher lumen output and proper beam angle will make these fixtures go farther apart and decrease the total amount of buildings and hence provides you with the best lighting solution and eventually reduces the installation post. A professional lighting service provider will be able to balance all of these features in a particular location such as LED high bay, LED linear high, or UFO LED high bay, according to mounting height, such as 15+ feet or higher and anywhere, depending on the amount of lumen output desired. Conversion of high bay lights do i need must also include whether high bay lighting is requisite for the performance and safety of your operations. Suggested unused terms: high bay light fixture spacing, linear high bay, free lighting layout, industrial lighting.

Should I place high bay fixtures close to each other?

Another important factor in the spacing of high bay fixtures is the luminaire positioning as the mounting height, the beam angle of the light and the required spread of light that would best fit the needs of your application drive the installation pattern. It is enjoined upon most lighting experts that the spacing of fixtures over mounting height, utilizing the spacing-to-mounting-height concept, can offer good spacing choices with high output-led fixtures; for example, fixtures at a height of 15 feet above average would have them spaced about as far as the mounting height but this varies. It is possible for lighting design software to simulate the increased spacing between fixtures while verifying whether the criteria for light quantity and uniformity within the space are met. By looking at the spacing in the lighting plan for linear high bay or metal halide light replacements, one might find spacing such that reaching the standard light levels with a lesser number of fixtures, and avoiding dark spots or darker spots in between, could be guaranteed. Suggested unused terms: proper high bay, lighting guide, bay lights do you need, number of led high bay.

How do I calculate the number of LED high bay fixtures required?

Deciding how many LED high bay fixtures you need starts with working out how bright the working tasks demand (in lux or footcandles) and the type of lumens the fixture outputs. Room size, desired brightness, light beam angle, and mounting height characterize high bay light fixture spacing and total fixtures; lighting apps or free lighting layout can simplify the calculation. Consider the efficiency of your lighting design and pick the right lighting fixtures (led linear high or ufo high) so that you aren’t over-specifying an excess of lighting units. For better results, have a lighting professional make a lighting calculation and advise you the best led lights for your space. Suggest: linear high spacing, multiple high bay lights, high bay lighting is crucial, spread of light.

What is the key to high bay light installments?

When planning a proper high bay installation, make sure to adopt a good fixture combination which, when it considers the beam angle, mounting height, and spacing of the luminaires, will ensure constant and bright illumination on the working plane. While a typical high bay design may seem to prefer LED fixtures or LED high bay LED lights for their quality as well as for their energy-efficiency with favorable spacing distance from each unit but to ensure that the visual acceptance and productivity improving lighting is proved using a lighting design computer program or confirmation from a lighting expert to see that the quantity of light and the ideal spacing are correctly implemented for safety and visual comfort. It is important for a big space, given the tasks performed and conditions that wish to be met, whether to critically decide on the replacement of older HID with better LED. Suggest idyllic extra topics professional lighting, lighting guide, high bay light fixture spacing, bay lights do i need.

Is it better to provide tightly spaced smaller lights or fewer lights with larger output?

It’s rather difficult to say whether to go for many lighting apparatuses or just a few higher-intensity ones. The former option deals with consistency, maintenance, upfront cost, and long-term balance. The latter would involve putting up a few lighting fixtures with higher power output; it allows wide spacing. Fewer fixtures setting closer to the ground offer reduced energy and maintenance overhead costs when compared to many fixtures running at a lower output, with overarching benefits in terms of redundancy in case some daylight management is also desired. You can model your own scenarios with software or have a lighting expert help you do it and look at the affected beam angle of light and some spreads with respect to how much light is useful to the purpose. The best led high bay fixtures for your space, by extension, will be determined by the number of led high bay units that you feel you’d go for, the spacing between the fixtures, and the efficiency of the type of lighting to give them merit. Suggested alternatives: led linear high, many led high bay lights, free lighting, and spacing to ensure.