High Bay Lights have become the go-to lights when it comes to lighting up large areas with high ceilings in industries and commerce. However, the way you mount these lights can greatly impact the efficiency, performance, and maintenance of the lights. It can be chain, hook, or surface mount, if you are retrofitting an existing facility, or setting up a brand-new warehouse, then accommodating these mounting options is the way to go for the best lighting results. This blog post will talk about these options, highlighting their different pros and cons, and assisting in finding the perfect one for you. Get yourself ready to comprehend the mounting methods that will not only brighten up your area but also elevate it in terms of image!

Understanding High Bays

What are High Bay Lights?

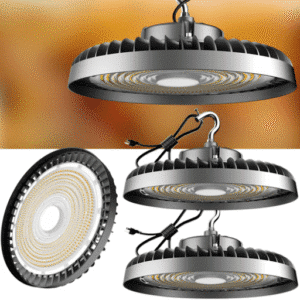

High bay lights, or high bay fixtures, are light sources that are bright and evenly distributed in areas with high ceilings of at least 20 feet from the floor. Such lights are mainly found in warehouses, factories, gyms, and retail stores to give good visibility in large, open spaces. The latest consumer interest signals that energy efficiency is the main concern, and that is why many companies choose LED high bay lights. Because of their characteristics, they come with less energy consumption and lower maintenance costs, the companies are opting for them. Their ability to work in various ways depending on the mounting is a plus and that makes them more adaptable to different harsh environments.

Types of High Bay Lights

High bay lights come in various types, each suited for different industrial and commercial applications. Current online data and search trends suggest that a few types of high bay lights are in high demand:

LED High Bay Lights

LED high bay lights are the most sought-after lighting solution, providing high energy efficiency and exceptional longevity. Their energy consumption is reduced by 75% as compared to traditional lighting; moreover, their lifespan can exceed 50,000 hours before a replacement is needed. This light type is widely customizable; thus, warehouses, factories, and large retail areas are its main users.

Metal Halide High Bay Lights

Metal halide high bay lights produce white light with a high intensity and are often utilized in areas which require high-intensity lighting. But on the other hand, energy efficiency wise, they are not on the same level with LEDs, and heat they produce is also more compared to that of LEDs. As a result the higher operating costs and energy inefficiency have led to their decreasing popularity, yet they are still to be found in places where bright, high-output lighting is prioritized.

Fluorescent High Bay Lights

Fluorescent high bay lights of T5 and T8 fixtures still come up as a considerably popular option in places where low upfront investment is acceptable. The power consumed and performance given is not the best but decent for commercial buildings and schools. However, they have shorter lives than LED lights and contain mercury which needs careful disposal.

All of these kinds of lights possess unique benefits and drawbacks, and picking the most fitting high bay lights depends on the height of the area, the intensity of light needed, and the budget constraints. LED technology was voted as the winner among other trends for its outstanding performance and profitability.

Applications of High Bay Lighting

High bay lights are necessary for various industrial, commercial, and recreation places where the ceiling height is at least 20 feet. Lighting solutions of this type are often used in warehouses, factories, and manufacturing plants to ensure that workers in large, open areas with high ceilings can safely see each other. Also, high bay lighting is a must in gymnasiums and sports arenas, which require uniform and bright lighting for the activities and events.

Recent search data shows that the demand for high bay lights, especially in the case of large department stores and supermarkets, has increased in retail. Not only lighting enhances the experience of customers but also marks the product displays effectively in such places. Similarly, the use of high bay light has extended to convention centers and exhibition halls, where lighting is a major factor in creating an attractive atmosphere. The high bay lighting, owing to its adaptability and power-saving feature, is never a problem when it comes to large-scale illumination requirements across the sectors.

Choosing the Right High Bay Mounting Option

Chain Mounting

Chain mounting is an adaptable and simple method for installing high bay lights. This method allows for the height of the lights to be easily adjusted to meet the specific needs of the space by just changing the chain length. It is a good solution in situations where the ceiling height is uneven or the precise location of light is very important. Chain mounting is very reliable because it is very strong and can hold the weight of most high bay lights, which is a reason why it is preferred in places like warehouses, factories, and other industrial sites. Moreover, it is so easy to install and maintain that it saves time and effort.

Hook Mounting

Hook mounting is an easy and effective way to install high bay lights. The fixture is hung on a hook that has been previously installed allowing for easy placement and adjustments. It is especially useful in factories where fast installations and moving lights are the requirements. Hook mounting is very strong and can carry the weight of the majority of high bay lights making it a safe and reliable option. Moreover, its easy installation process shortens time spent on installation and guarantees maintenance thus making it a perfect choice for warehouses and factories.

Surface Mounting

Surface mounting is one of the lighting fixture installation methods that do not only provide a fixed and secure option but also a method that is specifically for high bay light in places that a ceiling structure requires direct pole attachment. Surface mounting is often used in places with low to medium ceiling heights like retail shops, classrooms, and offices. This method guarantees stability and accuracy in lighting direction which is useful in providing light for different tasks or areas. Besides, the great improvement in LED technology, surfaced-mounted fixtures have become more energy-efficient and highly customizable in terms of their designs which would be compatible with modern aesthetic and functional needs.

Installation Guide for High Bay Lights

Preparing for Installation

Before the installation of the high bay lights, it is very important to take care of safety and efficiency first. First of all, have all necessary tools like a screwdriver, a ladder, voltage tester, and protective gear at hand. It is also very important to turn off the power supply in the area where the installation is being done so as to avoid electrical accidents. Take the measurements and make marks for installation with a lot of care to make sure they are in line with the layout plan for proper distribution of light. It is recommended that in the case of high ceilings, 15 to 20 feet, narrow beam angle fixtures should be used to effectively concentrate the light. Taking these details in advance helps to have an easier installation and the lighting system to function at its best.

Step-by-Step Installation Process

Step 1: Power Off

Before commencing the installation, check that the electrical supply to the location is fully turned off. This stage is critical for safety and it also prevents the occurrence of electric shocks during the installation procedure.

Step 2: Placement Measurement and Planning

Take the ceiling height and room dimensions measurements to verify the positioning of the high bay lights according to their beam angle and wattage. For instance, fixtures with a narrow beam angle are most suitable for ceilings with a height of 15-20 feet, while broader beam angles are for lower installations.

Step 3: Mounting Brackets or Hooks Installation

Mounting brackets or hooks should be fixed to the ceiling with a secure attachment following the type of high bay fixture you are using. Weight capacity of the fixture must be checked and the brackets should be spaced evenly to give a uniform lighting effect.

Step 4: The Fixtures Should be Wired

The high bay lights should be connected to the electrical wiring. Use wire nuts or connectors to securely join the wires, making sure to match the hot, neutral, and ground wires correctly. You may conform to the manufacturer’s wiring diagram for guidance.

Step 5: Clamping Fixtures to Mounts

The high bay lights are to be fixed onto the brackets or hooks that were installed before. They have to be firmly secured to rule out any possibility of their movement or instability.

Step 6: Change of Lighting Angle

After the installation, the angles of the lights are to be changed in such a way as to cover the area effectively and at the same time minimize shadows or glare. If needed, use tools to precisely direct them in line with the layout of the area.

Step 7: Installation Test

The power should be turned on again and the lights tested to ensure they are operating properly. Make sure there is consistent brightness and when there is, for instance, flickering, that the connections are checked again.

Step 8: Final Inspection

A complete thorough inspection has to be done for both safety and functionality. All connections, mounts and placements should be checked so that it can be confirmed that everything is installed correctly and working as intended.

If you closely follow these comprehensive steps, you will certainly get a professional and efficient high bay lighting installation that is customized very well for your workspace.

Avoidable Common Mistakes

When it comes to high bay lighting installations, not measuring the space accurately may cause improper light distribution which is one of the main mistakes that most people ignore while planning lighting layout. Unfortunately, they will end up with a layout that is not effective and still with poor aesthetics as a result. Furthermore, it is very easy to overlook the importance of checking the connections and mounts during installation and this could eventually lead to safety hazards or flickering issues. Doing proper wiring and securing installation should always be a priority and avoid rushing through the final inspection since this is the most important time to catch and fix any potential problems. Taking the proper time to properly plan and execute every single step reduces the risk of these mistakes happening and guarantees a successful lighting installation.

Factors to Consider when Installing High Bay Lights

Wattage and Lumen Output

A very important point that must be considered while choosing high bay lights is the wattage along with its lumen output as they are directly proportional to the sufficiency of brightness in that particular area. The wattage is the measure of how much power the light consumes, while the lumen output is an indication of the brightness level. There are cases where higher wattage does not mean increased productivity; therefore it is always wise to go for the LED lights which are energy efficient. The next assessment would be to measure the height and the area of the installation which would ultimately help in deciding the desired lumen output for lighting that wouldn’t be too glaring or shadowy. If the wattage and lumen output are properly matched to the needs of the space, it will lead to optimal performance and energy efficiency in lighting.

Color Temperature Selection

The temperature of the light greatly influences the mood and the function of the room. Light temperature measured in Kelvin (K) extends from warm white (lower values of Kelvin) to cool white and daylight (higher values of Kelvin). The warm white (2700K-3000K) is often used to make a space feel more welcoming and cozy, thus it is suited for homes like living rooms and bedrooms. While cool white light (3500K-4100K) brings a clear and plain tone, that works well for places like kitchens and offices where people need to do tasks. Daylight (5000K-6500K) imitates sunshine, so the fine detail and concentration are enhanced hence it is suitable for areas where people work or shops.

The less recent search trends depict that consumers are more and more inclined toward the selection of color temperature that is just right in terms of productivity and comfort. As an example, people often associate warmer colors with relaxation and mood-enhancing whereas for focusing and clarity cooler tones are searched. Mixing such preferences with particular usage situations can greatly help in an effective choice of lighting solution that caters to individual needs.

High Ceiling Considerations

Lighting design for high ceiling spaces has to carefully take into account the intensity of light, its distribution and energy consumption. High ceilings people install fixtures that emit a lot of light but only ensure that it reaches the far corners of the room evenly. Installing LED lights of higher wattage equivalents and having adjustable beam angles can possibly be a good choice for wide coverage. Furthermore, using dimmable fixtures one can control the atmosphere created while also keeping the glare down. It is important to realize that energy saving solutions are especially beneficial in such cases as they lower the cost of operations and also the environmental impact over a period of time.

High Bay Accessories

Additional Mounting Hardware

To the effective installation and stability of high bay lighting fixtures the additional mounting hardware plays a very important role. Common options are adjustable mounting brackets, suspension chains and hooks, which give the flexibility in positioning and height adjustment according to the needs of the space. These accessories are very helpful, especially to places with different ceiling heights and to odd-shaped buildings, ensuring that the light is well distributed. Choosing strong and compatible hardware is not only required for safety and long-lasting performance but it is also necessary to select the materials that can bear the weight of the fixtures and withstand the wear and tear over time.

Lighting Controls and Sensors

Lighting controls and sensors are the heart of the modern lighting systems providing energy savings along with enhanced efficiency and customization. The technologies allow the users to control light intensity, temperature and when it is on or off according to the needs. For example, motion detectors keep the lights off when the area is unoccupied thus conserving energy. On the other hand, daylight sensors keep adjusting the man-made lighting according to the natural light that is present, thus creating a pleasant and balanced environment. The interest in smart lighting solutions has increased greatly which reflects the trend of integrating advanced controls like voice commands, mobile app interfaces, and automated schedules in both residential and commercial spaces. Not only do these systems facilitate sustainable practices but they are also part of cost reduction and better user experience.

Safety Features and Compliance

The modern smart lighting systems offer a variety of safety features to the user in order to ensure the protection and reliability of the product. Some of these are surge protection, temperature monitoring to avoid burning, and compatibility with the industry standards such as UL certification or CE marking. Being compliant with these safety regulations is a must, as it ensures that the devices fulfill the acknowledged criteria for performance and safety. In addition, the majority of the systems offer secure encryption protocols to keep user data safe which in turn copes with the concerns of privacy and cybersecurity risks. The proper installation and following of the manufacturer’s guidelines further build up the safety and effectiveness of the smart lighting solutions in residential and commercial areas alike.

References

-

High Bay Capacity Utilization Tool – Discusses inefficiencies in high bay scheduling processes and capabilities. Read more here.

-

Structural Design of a New Reaction Frame for High Bay Laboratory – Explores structural design and mounting options for high bay laboratories. Read more here.

-

2015 UNH/NOAA Joint Hydrographic Center Performance and Progress Report – Includes discussions on high bay options and configurations. Read more here.

Frequently Asked Questions (FAQ)

What are the different mounting options for linear high bay and UFO high bays?

Suspended chains, pendant or NPT installation, surface mounting to the ceiling, and each has its own light output and lighting focused characteristics. Hanging installation for linear high bays and brackets for fluorescent tubes are most widely used for the even distribution of light across, while hooks or pendant mounts are preferred for targeted coverage in ufo high bay installation. Through the vapor tight high options, the lighting source and led bulbs are safeguarded in wet and dusty atmospheres. If commercial and industrial applications are concerned, it is better to consult a lighting professional who will help to pick the mounting option that fits the lighting requirement and the code restrictions. Suggested unused H2 terms: led light, industrial lighting.

What is the relationship between mounting and light output in general and efficiency?

Light levels will be different depending on the mounting height and method, so the installation of lights at 20 feet should use fixtures with high and low bay adaptability and suitable lumen output to fulfill the lighting requirements. Hanging installation or suspended mounting will improve light distribution and lessen glare compared to mounting directly to the ceiling, and by using led technology, lights will consume less power while still rendering high visible light and high performance. Linear led high bay lights can be installed in wide areas while ufo led high bay lights can be set in production zones where concentrated lighting is required. In the case of switched between or up-grade to led projects, compare light emitted, beam angles, and the range of options from commercial led fixtures. Suggested unused H2 terms: ufo led high bay lights, high performance.

What is the best mounting system for commercial and industrial uses?

The best mounting option is dependent on the area: for example, factories and warehouses usually have to use suspended mounting in order to have the light even all over the place, whereas places with storage or lower ceilings might prefer low bay or surface-mounted options. Linear high bay led lights are perfect for illuminating long aisles in trade and industrial lighting projects since they give light throughout the space, whereas LED UFO high bay fixtures are suitable for high ceiling areas that need intense center light. When deciding whether to fix the hook or use NPT installation, always keep in mind the light source, beam distribution, and maintenance accessibility. Upgrading to LED is a great way to achieve high performance and energy savings, but always consult with a lighting professional before finalizing the mounting method. Suggested unused H2 terms: led high bays, ufo light.

Can you say that UFO high bay lights are the best for high ceilings compared to linear high bays?

In very tall ceilings, mostly manufacturers prefer UFO high bay lights because round high bay shape and optics give a concentrated light output suitable for above 20 feet high or more spaces. Linear high bay lighting models and linear led high light work better when light evenly distributed and lengthy continuous lighting applications are required such as in aisles or assembly lines in commercial and industrial settings. UFO lights can be less in number but provide more luminous performance than linear ones which might need more mounting spots but produce higher uniform light levels. Take into account the different options of lighting depending on needs, light emitted, and whether the bay lights have dimming or controls before you make a decision between UFO and linear styles. Suggested unused H2 terms: industrial lighting, led light.

industrial lighting: What are the important installation aspects I should know about for both retrofits and new lighting projects?

When going retrofitting from incandescent to LED, it is necessary to assess the existing points where the lights were mounted, the strength of the ceiling structure for hanging lights, and the need for vapor tight high fixtures for harsh environments. In the case of new installations, it is important to determine the mounting method—hanging installation, NPT installation, or surface to the ceiling—based on the desired levels of light and energy efficiency goals, and subsequently select led linear high bay or ufo led high bay lights accordingly. Involving a lighting professional helps to ensure adherence to the regulations for commercial and industrial establishments and also to optimize the illumination output and fixture spacing for efficient performance. Besides, it is always a good practice to take into account maintenance access, whether lights are operated with controls, and the advantages of lights using less energy while giving better visible light. Suggested unused H2 terms: high performance, led high bay light.