Choosing the appropriate number of high bay lights for your area might be as difficult as solving a complex riddle. Proper lighting in warehouses, gymnasiums, and factories is very important for safety, effectiveness, and energy savings. However, how do you figure out the amount of light needed to get the bright spot you want without going over or under the light limit? In this guide, we will dissect the main elements that impact light patenting like ceiling height, room size, and lumen output, to enable you to make a wise choice. Continue reading to find out the mysteries of high bay lights, providing just the right light to your area!

Understanding High Bay Lighting

What is High Bay Lighting?

High bay lighting is a term for the lighting to be used in areas with high ceilings. Such ceilings usually go from 20 to 40 feet or even more. The lights in such places have to be of a high intensity and evenly distributed throughout the area. High bay lights are capable of doing all that and more. They even come with advanced technology to ensure energy efficiency and less glare. Their design distributes light evenly over the entire area, which is perfect for areas where precise lighting is critical and visibility is also a major requirement.

Benefits of Using LED High Bay Lights

LED high bay lights come with a lot of advantages which is why they have become the first choice in the very modern lighting solution. To begin with, they are energy-efficient to a great extent, consuming much less power than traditional lighting methods like metal halide or fluorescent fixtures. Hence lower electricity bills and less harm to the environment are the consequences. The second reason is that LED high bay lights have a life span of around 50,000 hours, sometimes even more, which means that maintenance costs plus replacements would be less. Besides that, these lights with their high color rendering index (CRI) ratings also give out light of superior quality and hence there will be great improvement in visibility and accuracy in work areas. On the other hand, the amount of heat generated by LED lights is kept to a minimum; that is why their use enhances safety and cooling costs are saved in the case of large indoor areas. With the technology continuously increasing, the majority of the LED high bay lights are now coming with smart controls such as dimming, motion sensing, and other customizable features that help in further optimizing energy use. The LED high bay lights are one of the best solutions if a business or a facility is looking for power; efficiency, durability, and performance.

Common Applications of High Bay Lights

High bay lights have been and are still in use in the areas where the ceiling is high and light needs to be very powerful and efficient. Warehouses, factories, sports halls, and retail outlets are some of the main areas of application. Besides, high bay lights can also be found in places like sports arenas, airplane hangars, and large storage areas. The lights are responsible for even lighting in very large areas which, in turn, increases safety and visibility in places where precise lighting is a must for operation efficiency.

High Bay Lighting Calculator

How to Use a High Bay Lighting Calculator

The high bay lighting calculator can be utilized by firstly figuring out the measurements of the area where the lighting will be installed, that is the length, width, and height of the room. Submit these measurements to the calculator along with directions like the kind of activity that is done in the room and the level of illumination that is preferred (measured in foot-candles or lux). Then indicate the kinds of fixtures that you intend to use such as LED, fluorescent, or HID lights, and also their wattage and beam angle. The calculator will then tell you how many fixtures there will be and where they will be placed in the room.

Considerations for Your Lighting Layout

The first step in design your lighting layout is to know the exact activities in the area and to choose the illumination levels that will be needed, which is usually in foot-candles or lux. The next step is to pick the installation’s (or application’s) fixtures that are the most proper, such as LED lights if power conservation is your priority, fluorescent for broader coverage or HID for the high-intensity needs, and then determine the wattage and the angles of the beam so that they fit the area. With the above information, you will be able to not only determine the number but also the strategic locations of the fixtures that will guarantee even and safe lighting, and consequently, efficient use of energy. Good planning not only makes the environment more pleasant but also uses energy more efficiently and saves on costs.

LED High Bay Lights Counting

The task of counting the number of LED high bay lights required for a certain area has many aspects to it in that it has to lead to the best space light and to be performed properly. First, evaluate the total area in square foot and determine the space function because, for example, precision tasks may require very good illumination. The height of the ceiling influences – very much – the angle of the beam and the wattage – high ceilings usually mean that you need more powerful fixtures with a narrower beam angle to supply light to the area effectively.

Another important aspect is lumens per square foot, usually known as foot-candles. For instance, in warehouses, the light requirement may vary between 10 and 30 foot-candles, while in manufacturing areas where work requires a lot of details the light requirement might be in the range of 30-100 foot-candles. After selecting the values, divide the total lumens needed by the lumen output of the LED high bay fixture you are planning to use. This will give you an approximate count of how many lights you will need in that area. Also, keep in mind the spacing that will be needed to get the light even throughout the area and to prevent both shadows and overly bright spots.

You will be able to create and improve your lighting plan matching your requirements by merging the details with the newest online resources, like energy-saving tips and advanced layout of lighting. Having a combination of fixtures and placement right not only helps in making the area brighter but also keeps the energy cost low due to efficiency and in the long run, it saves money through good visibility.

Lighting Layout and Spacing

Determining Optimal Spacing for High Bay Lights

The best high bay light spacing corresponds to the ceiling height and lighting level needed. For lights in areas with 15 to 20-foot ceilings where the intention is merely to light up the space, the good distance will be one of 12 to 15 feet between the lighting fixtures. If the light is aimed directly at an object or area to be seen, then the distance between the lights can be reduced to 10 to 12 feet. For areas with ceilings ranging from 20 to 30 feet high, the recommended distance for general lighting is 15 to 20 feet in spacing among the fixtures while the range 10 to 15 feet is for specialized lighting. The application of these guidelines will result in good illumination without any place being too bright or too dark leading to a well-lit and efficient environment.

Footcandle Levels Clarification

Footcandle levels are determined according to the specific lighting requirements of the tasks or environments. For general ambient lighting, the light intensity required in places such as hallways or corridors is usually in the range of 5 to 10 footcandles, while the light in classrooms or offices that are considered to be involved in moderate tasks may be 30 to 50 footcandles. Areas requiring great accuracy, like laboratories or microscopes, usually actually light up to 100 footcandles or even more in order to be certain of seeing and not making any errors. The larger the footcandle level determined for the space’s function the better the lighting will be in terms of both comfort and performance since the lighting will be the most appropriate for the particular use.

Reflectance and Its Influence on Lighting

Reflectance is one of the key factors determining the effectiveness of lighting within a particular space. It is the measure of how much light the surfaces reflect instead of how much they absorb, and thus it has an immediate effect on the overall lightness and mood in the room. White walls and glossy finishes are high-reflectance surfaces that can get the light levels boosted so less lighting fixtures are installed and the energy saved. On the contrary, less light is produced with darker or matte surfaces because these absorb light and more illumination is required to reach the same visibility. Knowing and applying reflectance in the lighting planning gives areas both energy-conscious and functional lighting along with the comfort of good vision.

Choosing the Right Fixtures

Types of High Bay Light Fixtures

High bay lighting fixtures are available in different forms, each suitable for different applications and environments. The main types are:

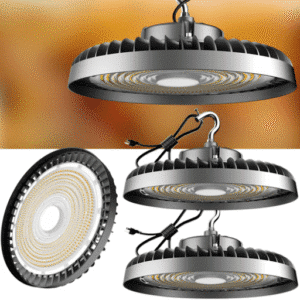

LED High Bay Lights – LED lights are the most energy-saving and eco-friendly fixtures, offering a long life with very little upkeep and providing bright, even light with different uses in common areas such as warehouses, factories, and sports. They can also result in huge energy savings when compared to the older lighting technologies as the LEDs consume significantly lesser power.

HID (High-Intensity Discharge) High Bay Lights – HID lamps are the earlier sources of indoor lights for the manufacturing and commercial sectors, especially for high-pressure sodium and metal halide lamps. Nevertheless, their use is declining as they consume more energy and have a shorter lifespan in comparison to LED lights.

Fluorescent High Bay Lights – Widely used for indoor spaces that require lighting in a wide area with diffuse light, fluorescent fixtures are both cost-effective and reliable. Nevertheless, they have a shorter life span than LEDs and could find it hard to work in extremely cold places.

Induction High Bay Lights – These lighting units are based on the principle of electromagnetic induction and have a long lifespan. They are best suited for places that require maintenance-free lighting, but their usage is not widespread as LED has overtaken them in preference.

Linear High Bay Lights – These light fixtures are made for the places that need a wider light coverage like the retail stores, school gymnasiums, and assembly areas. The LED option is available with them and it is always more energy-efficient.

In considering a high bay light fixture, factors such as ceiling height, the amount of light needed (lumens), color temperature, and energy efficiency should all be taken into account. LED technology is still the best option for most cases because it performs much better and costs less in the long run.

Evaluating Different LED High Bay Lighting Choices

It is necessary to assess some of the main factors when evaluating a range of LED high bay lighting solutions. The height of the ceiling is a very important factor since it influences the selection of the right fixtures; usually, taller ceilings require light with more lumen. The brightness that is required in the space measured in lumens, should correspond to the particular need and ensure the region is well lit and comfortable. Teas that color temperature should be chosen, for example, macro-appropriate; cooler temperatures (measured in Kelvin) suit task-oriented areas while warmer tones could be more acceptable in places where a relaxed atmosphere is desired. Energy efficiency is another important factor that should be considered and LED options have a great advantage over other technologies when it comes to power consumption and operating costs. Weighing these factors up helps to identify the most suitable lighting solution that meets the needs of the specific environment.

Tips for Selecting the Right High Bay Light Fixture

Determine the Appropriate Lumen Output

When selecting high bay light fixtures, consider the space height and size. For larger areas or with high ceilings, it is best to use high lumen output fixtures to get a good amount of light. Look at the lumen-per-watt ratio to put a priority on energy efficiency.

Evaluate the Color Temperature

Pick a temperature of light that increases visibility and also fits the purpose of the area. Cooler white light (5000K-6500K) is usually chosen in factories or warehouses where such light works best since it gives more focus and clarity. In contrast, warmer light tones (3000K-4000K) can be used in retail or public spaces as they are more inviting.

Choose Energy-Efficient Options

LED high bay lights have been the most energy-efficient option for lighting since they consume significantly less energy compared to metal halide or fluorescent lamps that are also being used. Modern LED lights have a longer life span which helps in reducing maintenance and replacement costs.

Assess Compatibility and Placement

Whether the fixture is going to be hung, pendant, or chain-mounted, make sure that it fits your mounting system. The height and placement of the light should be chosen to give an even spread of illumination and eliminate dark spots and glare.

Consider Durability and Ratings

In areas where there is dust, moisture, or extreme heat, fixtures with high IP ratings for dust and water resisting should be chosen. Also, check for certifications like DLC or UL to be sure of the quality and that it meets the required standards.

Explore Smart Lighting Options

Transform your lighting system into an energy-efficient setup that can adapt to changing conditions by using advanced technology such as smart lighting systems equipped with sensors for motion detection or daylight harvesting.

By following these tips and keeping yourself informed about the latest industry trends, you will be able to choose the perfect high bay light fixture that best fits your space, thus, increasing performance and energy efficiency.

Practical Examples and Calculations

Example Scenarios for High Bay Lighting

High bay lights are at their best in large areas like factories, sports halls, and storage places. For example, in the case of a storeroom with 30-foot-high ceilings, LED high bay lights of 20,000 to 30,000 lumens output are perfect to provide enough light for the activity of sorting and marking inventory. A sports hall similarly may use motion-activated high bay lights that are capable of cutting off power during no-use periods but still keep the place brightly lit evenly to be safe for sports activities. Factories usually have high-intensity lights that produce around 5000K color temperature to be able to see clearly for accuracy and create a relaxed atmosphere at the same time in the area of use. You can find out the exact high bay lighting solutions best fit each application by looking into the different requirements for each use case, such as the height of the ceiling, the kind of activities, and the energy-saving objectives.

Using the Room Lighting Calculator

The Room Lighting Calculator is a significant resource for correctly realizing the lighting necessities of a certain area. The calculator formulates personalized suggestions for high bay lighting solutions by factors like room size, ceiling height, and lux level requirements. Users will be confident that their selection is based on the present industry’s norms and best practices, For instance, a storeroom having high ceilings frequently gets lighting from LED high bay lights at a spacing ratio determined by the calculator which guarantees even and effective light distribution. Making the most of this tool alongside primary data from the real world, the decision-making process becomes easier and one can be sure that the lighting design is perfect for both sheets and energy conservation.

Evaluating Your Lighting Requirements

It is very helpful for the process of evaluating of your lighting requirements if you combine practical tools with the latest data. For example, by exploring essential developments in energy efficiency and spotting breakthroughs in LED technology, companies are capable of making more suitable lighting decisions that are specifically designed for their unique environments. data can also give answers to very specific questions such as how different color temperatures of light affect worker productivity or what is the energy rating of a certain product that is the highest. Incorporating real-time data into your decision-making process will guarantee that the lighting solutions you choose will be efficient as well as future-proof.

References

-

Electrical Energy Equipment: Lighting LIGHTING – A detailed academic document discussing lighting principles and advancements.

-

Energy Savings Estimates and Cost Benefit Calculations for High Performance Relocatable Classrooms – This paper includes calculations and data analysis related to high-efficiency lighting.

-

High-Intensity Discharge Industrial Lighting Design Strategies – A study focusing on lighting design strategies to minimize energy usage and lifecycle costs.

Frequently Asked Questions (FAQ)

How many lumens do I need for a high bay lit room?

The chief means to calculate the number of lumens necessary is to multiply the illuminating level (foot-candles) suggested for your space by the area of that room in square feet. This will then give the total lumens required. Proceed by dividing that figure by the lumen output of each fixture after making adjustments for the height of mounting, light loss factors, and reflectance to obtain an estimate of the number of fixtures. Alternatively, a high bay lighting calculator or lighting layout tool can take over these steps, accommodating real-life factors such as fixture spacing, beam angles and the like. Ensure to handle the task areas and aisles separately as they might require differing levels of illuminance; hence, it is essential to plan them wisely for the best lighting and safety possible. Suggested unused terms: many led high bay lights, lighting layout calculator, number of lumens, mounting height, foot-candle.

Can a led high bay lighting calculator tell me the number of lights you need for warehouse bays?

The answer is affirmative; a led high bay lighting calculator can provide an estimate of the quantity and type of lights needed by considering parameters such as the dimensions of the bay, desired foot-candles, the height at which the lights will be mounted, and the lumen output of the fixture. The calculator gives a visual impression of different layouts and often specifies a required ratio between spacing and mounting height to ensure that there is no glare and the coverage is even. It is recommended that the results be assessed against the safety standards and accessibility requirements in the commercial and industrial sectors to guarantee visibility and safety. For big warehouses, consider zoning and using fixtures with higher lumens to decrease the total number of lights while preserving adequate illumination. Suggested unused terms: many led, lighting projects, efficient lighting, high bay led lights, luminous flux.

Does the number of led high bay fixtures change with different mounting height and bay lights you need?

The height at which the lights are mounted has a dramatic impact on the spread of the light beam and the evenness of the illumination; therefore the number of required fixtures will vary when you raise or lower the lights. Lighting fixtures that are mounted higher generally need to have a more powerful output or a narrower beam to keep the same amount of foot-candles on the work plane. To get the most out of cutting-edge lighting, a lighting layout tool will model these effects and recommend changes in the number of fixtures, type (for example, UFO-style vs. linear), and spacing. Always consider maintenance factor and room surface reflectance since these will reduce the amount of light delivered over time. Suggested unused terms: optimal lighting, ufo, foot-candles, room dimensions, number and type of lights.

What are the steps to use a lighting layout tool or led lighting calculator for a new industrial lighting project?

First, measure the room dimensions, the height of the lights, and the level of illuminance (foot-candles) that the workers or the area for the task requires. Enter the characteristics of the lighting fixtures (lumens, beam angle, and mounting type) into the lighting design software and create a layout to inspect coverage, uniformity, and the pointing recommendations. Work with different fixture outputs and spacing until brightness, uniformity, and energy goals are reached; also consider glare and maintenance factors. Finally, compare the layout with industry-recommended illuminance levels and if necessary, consult lighting experts for final adjustments. Suggested unused terms: led wall, efficient lighting, lighting layout tool, number of fixtures, visibility, and safety.

How can I determine how many many led and many lumens are required to light a workspace effectively?

Finding out how many LEDs and how many lumens you will need involves measuring the room in square feet then multiplying by the desired foot-candles to get the total number of lumens needed for the workspace. Divide that total by the output of your LED fixture lumens and adjust for light loss factors, reflectance, and desired uniformity to get an estimate of the number of fixtures. A high bay lighting calculator or lighting layout calculator will be able to quickly do these calculations and provide realistic layouts showing different fixture choices. Based on task-specific lighting requirements and possible zoning, find a balance between visibility and energy efficiency optimization. Suggested unused terms: led lighting calculator, sq ft, workspace, number and type of lights, professional lighting.