The utmost priority in the case of food processing plants is to always have a secure and hygienic working environment that is also efficient. In this scenario, every aspect, even the machinery and lighting, has to be of top quality to guarantee adherence to the strictest industry regulations. NSF Certified LED High Bay Fixtures are the solution to that problem. These specific lights are made not only to bright up large areas very well but also to satisfy the very high cleanliness and safety standards of food processing plants. We will detail in this article why NSF Certified LED High Bay Fixtures have become a must for the professionals of the food industry, how they aid in gaining operational efficiency, and lastly, we will point out why improving of your facility’s lighting to these top-notch solutions could actually be a game-changer.

Importance of High Bay Lighting in Food Processing

Understanding Food Safety Standards

Food quality controls are categorized into various practices and regulations that keep food products safe for human consumption and completely free from any further impurities. These controls are first defined by the FDA and then their requirements become law, e.g. cleanliness, maintenance of machines and all kinds of appropriate staff practices within the food processing plants. Following these rules helps to end of food pollution and outbreaks, guarantees a particular standard of the product, and builds trust in consumers. The use of the illuminated and certified tools such as the NSF Certified LED High Bay Fixtures, helps to achieve these goals by creating the desired environment of cleanliness and well-lit-ness which is the pre-requisite for safe food processing.

The Significance of Lighting in Food Processing Industries

The food processing industry relies on proper lighting for the health of the entire chain, as well as the quality of the end product. Adequate lighting allows the employees to do their job perfectly; it also makes cleaning and inspection so much easier hence the risk of contamination goes down; and it contributes to the observance of harsh food safety legal standards working hand in hand with lighting. The installation of high-grade lighting like NSF Certified LED High Bay Fixtures creates the interplay between the two worlds – productivity and cleanliness – since such fixtures will provide wide bright illumination and at the same time be easy to clean and weather resistant which is a characteristic of food processing plants. So, lighting is not only a tool that consecutively improves the operations of the plant but it also a key element of public health protection.

Reasons to Switch to High Bay LED Lights

High Bay LED lights are among the best options for industrial and commercial facilities due to their many benefits. These lights are green and energy-efficient, using a lot smaller amount of electricity compared to traditional lighting, which in turn helps to lower the electricity bill over a period of time. They still do not compromise on brightness and can cover a large area providing 100% light with all shadows eliminated. Furthermore, High Bay LED lights are long-lived, thereby reducing their operating costs and minimizing their perpetuity lifecycle. They are also built so strong that they can withstand the ill effects of environmental extremes, hence, they would always work effectively even in the strictest food processing plants. Their surface is not only easy to clean; it is also eco-friendly which are the two reasons to combine hygiene with support of sustainability goals.

Types of High Bay Lights

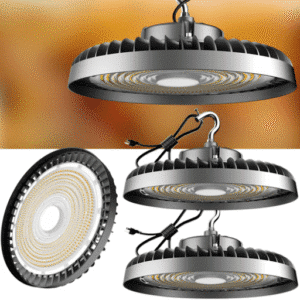

UFO High Bay Fixtures

The UFO High Bay lights operate under the principle of round design that is in the shape of disks, which are much the same as flying saucers, and that grants them the ability to distribute light evenly and efficiently. These light fixtures find their best application in places with ceilings that are very high, such as warehouses, factories, and sports halls, where they contribute by using less power to provide. The design is small enough to make both installation and maintenance easy; on the other hand, the quality is such that they will not fail even in hard environmental conditions. What is more, UFO High Bay lights operate at a very high energy efficiency making the electricity consumption and thus the operational costs even smaller than the life span of the lamp itself.

Comparison Between Traditional HID Fixtures and LED High Bay Lights

The comparison between traditional HID fixtures and LED high bay lights reveals a huge gap in performance and efficiency. HID fixtures, although previously widely used, are high-energy consumers and at the same time suffer from the disadvantage of dissipating a lot of their energy as heat, so that the power consumption and maintenance costs go up. Besides, their lifetimes are short and hence they need frequent replacements, which translate to loss of productivity and inconvenience. LED high bay lights, in contrast, are highly energy-efficient; their power consumption is much less than that of the light output, which is bright and uniform. Let’s also mention that LEDs last longer, require less maintenance, and withstand better the roughest conditions. Furthermore, LED lighting offers an increased color rendering capacity and an almost instant warm-up time which surely counts in favor of its adoption in lighting-up technological applications.

Choosing LED Options for Food Applications

For a choice of LED options that concern food applications it is very important to begin with those fixtures that are compliant with the most stringent hygiene and safety requirements, such as NSF certification or an IP rating that protects against dust and moisture. Select LEDs that are made of durable, non-toxic materials and have a smooth surface that is easy to clean to ensure that you are complying with food industry regulations. In addition, the LEDs should be energy-efficient, emit low heat, and have excellent light quality that will help to keep visibility and operational efficiency in food processing areas. These advantages will not only provide safety but also long-term cost-effectiveness.

Key Features of High Bay Lights

Lumen Output and Efficiency Considerations

Lumen output and efficiency are the main aspects that one must consider when choosing high bay lights for food processing areas. The higher the lumen output the more light and the better illumination in a uniform way in the entire area thus, improving visibility and safety for employees. Good LED lights, on the other hand, consume less electricity thus, lower operating costs and power consumption which makes them eco-friendly in the long run. Find lights that have a high lumens-per-watt ratio so that you do not only get brightness but also efficiency, and that these are the lights that have been designed for maintaining consistent performance for a long time with little or no degradation.

IP69K Rating for Food Processing Facilities

Important: The IP69K rating is the topmost class of ingress protection, and it is specifically meant for the surfaces that need to be thoroughly clean and sanitized, like food processing plants. The IP69K rating gives a green light for the use of the equipment even in the harshest cleaning environments of dust, high-temperature water, and high-pressure cleaning. This means that they can be washed down with the toughest methods and still keep their functionality and hygiene standards, thus being ideal for the strict cleanliness requirements in a food processing area.

Understanding DLC and UL Certifications

DLC (DesignLights Consortium) and UL (Underwriters Laboratories) certifications are markers of quality, efficiency, and safety for lighting products. The DLC certification allows a product only if it meets the stricter performance and energy efficiency criteria, which sometimes makes it entitled to utility rebates. Unlike this, UL certification focuses on safety and confirms that a product has been through rigorous testing and thereby is safe from electrical hazards and can be used safely. The two certifications combined let both the consumer and the professional to be sure that the lighting fixtures are reliable and safe for use in different surroundings.

Installation and Maintenance of High Bay Lights

Best Practices for Installation

The proper installation of high bay lights is very important as it directly determines their effectiveness, durability, and safety. First, read the manufacturer’s installation manual carefully since it contains instructions that are very particular to the product. Always ensure that the power is switched off in order to eliminate the risk of electrical injuries during the installation. The right mounting method should be determined according to the ceiling type and height—typical mounts are chain, hook, and pendant. Check that the lights are firmly installed and all the connections including the wiring are insulated to avoid short circuits.

For the best performance, distribute the high bay lights uniformly and take into consideration the factors like lumen output, distance between lights, and angle of light. This will provide the necessary brightness in the area without the disadvantage of too much lighting or dark spots. Besides, reducing the lighting to a minimal level or using motion detectors can be considered as letting energy-saving measures be dictated by the spaces usage patterns.

In conclusion, put the installation to the test before normal operation and eliminate any flickering, dimming, and overheating problems. If difficulties arise or the installation requires complicated adjustments, consult a licensed electrician. A combination of regular maintenance and following these recommendations will not only ensure the high bay lighting system’s productivity but also its longevity.

Regular Maintenance for Optimal Performance

Maintenance done on a regular basis is the most important step to keep your high bay lighting system running efficiently. To begin with, the fixtures should be cleaned at intervals so that dust and dirt that might interfere with light intensity are eliminated. Check the lights for any problems such as broken bulbs or flickering, and replace them at once. Inspect all electrical connectors and cables for any loose or damaged parts that could lead to reduced performance or safety risks. Make sure there is enough airflow around the fixtures to prevent overheating and to increase their lifetime. Following a routine maintenance plan will not only help in keeping performance at its peak but also lessen the occurrence of expensive repairs.

Understanding Warranty Options

Coverage details and duration offered by the manufacturer or retailer should be the main points to consider when looking at the different warranty options. Find out if the warranty will cover parts, labor, or full replacement in the event of a defect or malfunction. Check whether there are any conditions that may void the warranty, like incorrect installation or neglect of regular maintenance. Moreover, find out about the claims process, including when you can expect a response and whether there will be any additional costs, such as shipping, involved. Gaining a comprehensive understanding of these points will enable you to choose a warranty that provides reliable protection and peace of mind.

Energy Efficiency and Rebates

Impact of LED High Bay on Energy Consumption

LED high bay lights are known to save considerable amount of energy because of their efficiency which is much more than the traditional lighting systems and the likes of metal halide and fluorescent lights are their predecessors in this regard. The amount of power consumed is much less than that of the traditional systems but the output of light is equal or even greater, making the electricity bills to go down. Besides, the long life of the lights also means that replacement is not done frequently, hence less maintenance cost and waste of energy associated with disposal of old lights. Therefore, installation of LED high bay lights is a win-win situation for businesses as they get instant cost savings and at the same time, help in energy saving and eco-friendliness.

Rebates Available for Upgrading Lighting Fixtures

Replacing lighting fixtures with energy-efficient products like LED high bay lights can make businesses qualify for different rebate programs that are offered by utility companies and local governments. The purpose of these programs is to enhance energy savings through providing financial incentives for the installation of environmentally friendly technologies. Often, rebates help cover part of the initial costs that businesses have to incur, thus, making their transition to LED lighting cheaper. The specific rebate amounts and eligibility requirements differ depending on the location and provider; firms might be able to receive instant discounts at the cash register from some utilities while others will request an application to be submitted after the installation for consideration. Moreover, federal tax credits and grants for energy efficiency might lessen the financial impact of upgrading the lighting systems. It is advisable for businesses to reach out to their local utility suppliers or energy efficiency programs to find out about the available rebates and enjoy the maximum savings.

Calculating Long-term Savings

For the purpose of calculating long-term savings, my first step is to estimate the LED systems installation cost and compare it to the time when the energy savings would have been enough to cover the cost. I also count in the present rate for electricity, possibilities of an increase in that rate, and the duration of the upgraded systems. When considering utility rebates, tax credits, and reduced maintenance costs, I can then arrive at an estimate of the total financial gain. This approach not only gives me the ROI but also makes sure the upgrade is in line with my budget and eco-friendly aspirations.

References

-

Energy-Efficient Agricultural Lighting

Published by the University of Wisconsin, this document discusses energy-efficient lighting solutions, including applications in agricultural and food-related environments.

Read more here -

Electrical Energy Equipment: Lighting

This academic paper provides insights into lighting requirements for various industries, including food processing.

Access the document here -

Management Information Systems in Retail Food Firms

This resource explores the use of technology and lighting in food retail and processing industries.

View the source here

Frequently Asked Questions (FAQ)

How would food and beverage highbay lamps operate in a food safe manner?

The food and beverage highbay lamps fitted in the processing areas are marked under the NSF sterilization standards and have food-safe coatings applied to them so as to lower the chances of any contamination happening. A lot of models come with polycarbonate lenses as well as prismatic lens options, and the sealed aluminum housing prevents dust, moisture, and bacteria from coming in. Alongside the aluminum body that has the corrosion-resistant coating, the exposed hardware protection helps in reducing the effects caused by corrosion and cleaning in harsh environments making made easier. The rated LED modules that don’t emit any harmful substances and the NSF-rated drivers work to output the same light consistently without any gassing or flaking that could otherwise cause a contamination of product lines.

What is the signature of a food and beverage LED luminaire that marks it as a premium and high-performance model?

Generally, the premium type of food and beverage LED luminaire will be the one that includes high-performance LED technology, robust aluminum housing, and a photometric design that has been put through testing to give the same output of light throughout the production area. The combination of the DLC Premium listing, the compatibility with 0-10V dimming, and the use of rated LED modules will surely mean that the power consumption is low, and you have the option to control the light levels. In addition, high-performance models usually have a color temperature of 5000K, allowing for more accurate color rendering and clearer visual inspection of products. Long warranty periods like 5-year warranty and an aluminum body that is rugged, corrosion-resistant, and subject to 5-year warranty all make significant contributions to lifecycle value even in harsh environments.

Are highbay lamps meant for food and beverage processing areas approved for use in sanitary and washdown areas?

Yes, a number of highbay lamps designed for use in food and beverage processing are indeed sanitary and can be washed down as they utilize sealed housings, NSF certified components, and polycarbonate lenses which are able to withstand chemical cleaners. Over the aluminum housing with the appropriate gaskets, the sealed lens prevents moisture and bacterial infiltration, and the corrosion-resistant finishes safeguard the fixture through repeated cleansing cycles. The fixtures designed for food processing maintain a prismatic or polycarbonate lens which sheds debris and withstands the sanitizing chemicals used in food processing. Do not forget to ensure the luminaire is listed for sanitary environments and has minimized or eliminated exposed hardware to lessen the traps for contamination.

What are the ways in which LED food processing high bay lights are made suitable for harsh environments and corrosion?

LED food processing high bay lights for harsh environments usually come with an aluminum housing that has been coated to be corrosion resistant and with sealed housings that can keep moisture and chemic moisture and chemical damage out. The construction is rugged, the materials used are either stainless or protected exposed hardware, all are complemented by the polycarbonate lens options that bring about the durability where the washdowns and chemical exposure are frequent. When one chooses rated LED components and a proven luminaire design, one is not only extending the service life but also maintains lumen maintenance in aggressive conditions. Notably, some manufacturers provide models with additional IP ratings and NSF certification to prove further that the products are suitable for use in food and beverage areas.

Do food and beverage highbays have the connectivity to the dimming and control systems like 0-10V?

Indeed, an overwhelming number of food and beverage highbay LED luminaires come with the support for 0-10V dimming and also compatibility for facility-level control systems for energy savings as well as task tuning. Power consumption during low-demand, 0-10V dimming enables gradual adjustments and integration with occupancy or daylight sensors. The controls should always be chosen in a manner that allows the food safety protocols to be maintained, and the wiring and control modules to be installed in a serviceable, sealed location. The lifespan of the LED can be significantly increased when the dimming is paired with high-performance LED technology, and the visual comfort for inspectors and line operators is also improved.