Cold storage facilities and industrial freezers need the proper lighting not just for visibility but also for operational efficiency, safety, and energy savings in very harsh conditions. Therefore, high bay lighting fixtures are designed with the specific characteristics of these cold areas in mind, such as extremely low temperatures, moisture resistance, and compliance with the strictest standards in the industry. This blog post is intend to discuss the application of high bay lights in cold storage and freezer where, at the very least, the right lighting technology can reduce energy costs, improve performance, and provide a safe and productive work area. Come along with us as we uncover the critical factors considered in the design of a lighting system that would be both efficient and reliable for your facility.

Understanding High Bay Lighting

What is High Bay Lighting?

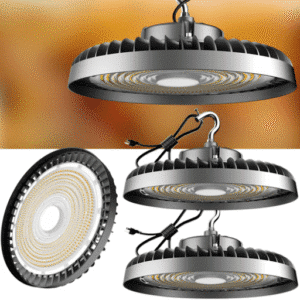

The term ‘high bay lighting’ indicates the adding of lighting fixture with the highest light production that is purposefully built for buildings with very high ceilings; typically these ceilings are between 15 and 50 feet. The primary reason for such lighting is to adequately illuminate large areas so that workplaces such as factories, warehouses, cold storage units, and even big plants get only strong, nice, and uniform light. The manufacture of high bay lighting fixtures includes not only LED lights, but also fluorescent and metal halide sources just to mention a few; the consideration being the various needs of different operations. Their durable construction together with the high lumen output ensure the safe and effective carrying out of tasks even in difficult areas.

Benefits of High Bay Lights in Cold Storage Facilities

High bay lights provide cold storage facilities with numerous benefits since the latter mainly rely on good lighting for safety and operation efficiency. The fixtures are designed to operate in very lowtemperature environments and thus they will still be bright enough. Among the high bay lights, the LED ones are the most eco-friendly and produce little heat which is an advantage because it will not cause the storage area to become warmer than it is supposed to be. Their long life span means lesser maintenance which consequently leads to fewer operation disruptions. Likewise, high bay lights allow for even lighting thus eliminating darkness and increasing visibility for all the persons working in the area. This way, activities like inventory control and equipment handling will be done rightly and safely.

Common Types of High Bay Fixtures

Each type of high bay fixture has a different variety, is versatile and tailored to the specific application and operational needs. The following are some of the most common types:

LED High Bay Lights

LED High Bay Lights have lower power consumption and this whole power consumption becomes a savings source at the end of the month because of the cheap electricity bills. Moreover, large companies usually with a lot of bulbs are going to see these LEDs as very long-lasting light sources, as the life of these bulbs is often well over 50,000 hours, and this feature is one of the main reasons that they are the best choice for industrial places that do not get dark often. The brightness as well as uniformity are to be counted as the main characteristics of these LEDs which thus help in enhancing the visibility and safety of places like warehouses and factories.

Fluorescent High Bay Lights

Fluorescent high bay lights are likely the most widely used category of lights in factories and other areas where there is a budget constraint. They are bright, therefore, easily used in areas with less critical requirements regarding durability and temperature. However, their energy consumption and lifetime are not as good when compared with incandescent lights, and pharmacy-like disposal measures are in place to avoid possible mercury contamination.

HID (High-Intensity Discharge) High Bay Lights

HID lights which include both metal halide and high-pressure sodium, were the first and foremost lighting solution before the coming of the LEDs. They emit super bright light but at the same time, their disadvantages are that they are slow to warm up, consume more power, and the light gets less effective as they age. Despite these drawbacks, they are still usable in certain applications where light intensity is the key factor.

Induction High Bay Lights

Induction lights are very strong and efficient at the same time, therefore they are a very good option where the only condition is no maintenance is to be done regularly. The source of their light is not the usual filaments or electrodes but rather electromagnetic fields which is the reason why their lifetime is so long. From time to time, you can see these fixtures being used in some or the other location but for the most part, it is the LEDs that have completely taken over the torch light of induction and now also that of energy efficiency and cost-effectiveness.

A thorough evaluation should consider factors like energy efficiency, maintenance cost, illumination levels, and application-specific requirements when choosing a high bay fixture. The ceaseless innovations in LED technology have, without a doubt, and to a great extent, eclipsed other lighting modes in the high bay lights market, as it is the most dependable and future-proof option.

Cold Storage Facilities and Their Lighting Needs

Importance of Proper Lighting in Cold Storage

The most important thing about lighting in cold storage buildings is that it gives three benefits; safety, efficiency in running operations, and the quality of the products. With proper lighting, the area will be clearly visible and workers will be able to handle the goods safely in the cold area with the help of light. On the contrary, poor lighting can be a risk factor along with the consequences of frost, condensation, or glare. A good quality lighting is not only a help in managing the stock correctly but also a cause of reduction in mistakes through evenly and adequately distributed light across the whole area. In addition, lighting solutions in cold storage are expected to be energy-saving and durable at the same time. The low heat emission, high durability and reliable performance in cool environments making LEDs the most suitable option for such applications as they are both cost-effective and trustworthy.

Cold storage lighting efficiency factors

There are numerous factors that affect the efficiency of lighting in cold storage facilities such as the one regulating the temperature, using energy, and giving light. The light sources should not only be resistant to low temperatures but also work efficiently as extremely cold conditions could severely reduce the output of some technologies like ordinary fluorescent bulbs. Energy efficiency is essential as it always costs a lot to run a cold storage plant where inefficient lighting wastes electricity. Besides, lighting everywhere is a must so that no dark areas which might be unsafe and also obstruct visibility are created. LEDs have become the preferred choice of lights because they offer energy efficiency that is high, light output that is even and stable, and an excellent ability to resist cold conditions all at once. The role of proper installation and maintenance in achieving long-term efficiency is also very significant.

Factors to Consider

The number one factor in determining the proper high bay lighting for cold storage facilities is by taking a closer look at the major drawbacks discussed above in order to achieve the best performance, maximum efficiency, and the longest lifespan. Two of the latest discoveries point to the fact that LED-powered lights are now the premier choice for high bay lighting in-freezer facilities because they withstand the brutal temperatures of -10°F to -40°F that are commonly found in these places. The LEDs are not only energy saving but also provide light output that is equal to that of aging technologies like metal halide and fluorescent lighting systems which require a considerable amount of time to warm up before actually becoming luminous.

Another very important factor, the one related to the visibility and recognition of the goods stored, is the CRI or color rendering index of the light. The industry usually accepts the minimum standard of 80 CRI for the lighting of cold storage as enabling the colors to be true to life and reducing the risk of accidents in operations. Moreover, the IP ratings (Ingress Protection) serve to demonstrate how well the lighting systems are able to withstand the humid and frost-prone conditions typical of cold warehouses. Generally, light fixtures with an IP65 rating are highly recommended as they offer excellent protection against moisture and other environmental factors that may cause leakage.

Besides, there is still the case of intelligent lighting solutions that integrate motion sensors and automated dimming systems which have gained wide acceptance. Such lighting systems utilize only the active light when it is actually required, thereby resulting in quite a substantial cost saving in the long term. To obtain both the full advantages of energy efficiency and easy operation in cold storage premises, it is recommended that the LED high bay lights be combined with advanced control systems.

Evaluating Lighting Efficiency

Understanding Lumens and Their Importance

The lumens represent the visible light that a lamp emits totally and are a parameter of great importance in terms of energy efficiency. However, power consumption is not indicated, and hence luminance is the only measure that reveals the brightness of a light source. This distinction holds a very critical significance in the context of lighting such areas where energy is intensive, since the lm/W (lumens per watt) ratio certainly points to higher efficiency. For example, in cold storage facilities having high illumination all the time, a proper grasp of lumens aids in the selection of a lighting system that is both economical and gives good visibility. The focusing on lumens instead of power usage allows the customer to weigh brightness against energy and operating costs via an informed decision.

The Effect of CCT on Lighting Quality

Correlated Color Temperature (CCT) is the main predictor of light’s characteristics and its use in different locations. The CCT expressed in Kelvin (K) not only tells about the shade and color of the lamp’s white light but also ranges from warm (lower Kelvin values) to cool (higher Kelvin values). For example, the warm light with a CCT of 2700K–3000K generally brings a pleasant and relaxed atmosphere, thus it can be used in living rooms and places where comfort is desirable. Conversely, the cool light between 5000K and 6500K range makes things clearer and allows one to concentrate better, making it suitable for high precision activities like labs or factories.

Recent data analysis uncovers a tendency to match CCT to specific applications not only to uplift usability but also to enhance user satisfaction. search engine data supports this trend as it shows a sharp increase in searches for “best CCT for productivity” and “daylight-emulating LED lights”. It means that people’s lighting needs are both biological and psychological at the same time. For example, it has been found that CCT close to natural daylight (around 5000K) is excellent for the human circadian rhythms, thereby, keeping individuals awake and active in office or hospital environments. Conversely, lower CCTs are often adopted in hospitals or hotels at night as they help guests fall asleep by mimicking the warm colors of the evening lights.

Knowledge of CCT and its selection is necessary not only for aesthetic purposes but also for energy efficiency and performance of the task. The advance of LED technology which provides the user with the option of changing color temperature has granted them the freedom to change the CCT at any time, therefore, it provides flexibility and at the same time caters to different lighting requirements with a single system. This implies that accuracy in controlling CCT is of utmost importance in modern lighting design if we aim to optimize the quality and health impacts, as well as the operational results, across different environments.

Wattage Issues for Energy Saving

In terms of energy saving, it is critical to connect power consumption to the appropriate light output which is usually done by utilizing the lumens per watt (lm/W) measure. The more efficient the lighting system, the more lumens it produces through the least power consumption, which is the case with, for instance, LED technology that is already the best choice for energy cost reduction. In addition, the use of lamps with dimmer switches also gives one the power to be much more flexible when it comes to different lighting levels and therefore controlling energy consumption in various places. Among the factors that should be taken into account are the lighting operating hours and total load since they significantly influence the system’s energy consumption and performance over time. By adopting systems that come with advanced energy management features, companies can not only significantly reduce their expenses but also become more eco-friendly.

Installation and Maintenance of High Bay Lights

Best Practices for Installing High Bay Fixtures

The installation of high bay fixtures is an art that calls for detailed planning and following specific practices in order to obtain the maximum performance and safety. First of all, the layout of the building and the height of the ceiling should be evaluated so that the best locations and distances between the fixtures can be established which, in turn, will be a significant factor for how even the light will be distributed. Secure the lights with the suitable mounting hardware that is specifically for the ceiling type being used, which could be hooks, chains, or brackets. As well ensure that your entire electrical connections are up to the standards of the area’s codes and standards, and alongside that, employ quality wiring to minimize the risks of energy loss or hazards. When selecting the fixtures for such environments that need extra durability, make sure they have the proper ingress protection (IP) ratings that will cope with dust, moisture, or any other rough conditions. Each fixture testing after the installation is a significant practice that helps in verifying the correct functioning and positioning of the fixture. In addition to this, following these practices not only results in the lighting performance being optimized but also in the longevity and efficiency of the system being improved.

Maintaining High Bay Lights in Cold Storage Environments

Cold storage environments have very low temperatures and extremely high humidity levels, which can be a cause of the high bay lights to perform less than expected or even to be damaged. Therefore, taking into account the use of lighting fixtures that are especially designed for cold conditions is one of the most important points, as they are often rated for very low operating temperatures. It is important to carry out regular inspections to see if there are any signs of condensation, corrosion, or worn-out parts, as these can all disrupt the proper functioning of the system. The use of a proper cleaning agent that is non-corrosive and suitable in cleaning the fixtures regularly will help in keeping the frost or dust from accumulating. Furthermore, ensuring that the sealing is proper and also checking the ingress protection (IP) ratings can reduce the effects of moisture or ice in causing damage. Maintenance program that is scheduled and addressing problems immediately will not only keep the system operating at maximum efficiency but also maintain the lighting levels even.

Upgrading to LED High Bay Lights for Improved Performance

The performance of LED high bay lights is greatly enhanced as they are more energy-efficient, have longer lives, and are less of a maintenance bother. Personally, the transition to LEDs is sure to bring not only better lighting with higher lumens and better color rendering but also a reduction in operational costs because of the decrease in energy consumption. This decision is a clever, with an eye on the future, way of acquiring dependable, top-quality light in severe working environments.

References

-

Wisconsin Energy Efficiency and Renewable Energy

This source discusses indoor lighting solutions, including high-output T-8 or T-5 lamps and LED bulbs for cold environments.

Visit the website -

Non-Refrigerated Warehouse Design Guide (NREL)

This guide includes information on lighting design and energy efficiency for storage facilities.

Visit the document -

Nonresidential Indoor Lighting (California Energy Commission)

This document covers high bay and low bay lighting fixtures, including their applications in various environments.

Visit the document

Frequently Asked Questions (FAQ)

Industrial highbay lighting: What are the benefits for cold storage facilities?

The benefits are safety and efficiency in cold storage with specific Industrial highbay lighting meant for freezing. It gives brighter and more uniform illumination, which, at the same time, reduces picking errors in warehouses and distribution centers. The maintenance-free lighting modules are equipped with spread lenses which can cut energy consumption and labour costs to a great extent while still meeting the food safety and NSF requirements of the State of California in food processing and food and beverage environments. Surged protected power supply is provided to the equipment manufacturers for direct and indirect food cooling, thus ensuring the proper operation of the cooling units. The integration with 0-10V or 120-277V control systems allows dimming and advanced lighting strategies to further cut turnover and operating expenses. Highbay fittings specified correctly also minimize maintenance and support efficient space utilization and higher storage density with narrow aisle and pallet rack configurations. Suggested unused terms: warranty, SKU, forklift.

Demand for energy-efficient lighting: How do I choose the right fixture for refrigerated aisles?

It is first wise to put energy efficiency and durability at the top when choosing fixtures for refrigerated aisles and then to select fixtures that are rated for low temperatures and condensation resistance in order to protect the module and lens. Look for systems that include 0-10V dimming or advanced lighting controls to modify light levels depending on occupancy and demand, thus lowering the power supply load and overall costs. Consider products with tough housings and IP ratings which can keep the fixtures out of the areas where the forklift traffic and frost are in the narrow aisle and pallet rack environments. Integrating with building controls and sensors makes it easier to manage operations and empowers distribution centers and storage warehouses in reaching their sustainability objectives. Ensure that safety standards are met and that surge protection is installed for the selected fixtures, so performance remains reliable even in unfavorable conditions. Suggested unused terms: power supply, storage solution, diffuse.

Industrial demand planning: Can lighting affect food safety and refrigeration efficiency?

Lighting definitely does such in a negative manner through heat gain; it adds to the heat and causes the refrigeration system to work harder than it should which eventually leads to food safety issues in processing and storage for the food and beverage industry. On the other hand, LED highbay solutions emit negligible heat as compared to traditional lamps, thus enabling the refrigeration system to work within its setpoints with less frequency of compressor cycling. The lighting designs using diffused lenses and aisle orientation direct the light away from the unnecessary cold mass thus saving energy and increasing material turnover in storage. One should always check with the NSF and other food safety standards when installing lighting close to exposed food or open processing areas. Besides, properly designed lighting will link with the SKU picking accuracy and labor cost reduction as it will support more efficient operations in pallet racks and narrow aisles by improving visibility. Suggested unused terms: warranty, 120-277V, integration.

Industrial-grade highbay fixtures: What maintenance and warranty considerations should I expect?

When looking for industrial-grade highbay fixtures for cold storage, it is necessary to be aware of the warranty terms that are robust and reliable, documented under low-temperature operation and frequent cycling conditions. The use of rugged construction, replaceable modules, and ventilation designs that prevent condensation and contamination will all lead to less frequent maintenance intervals in storage and distribution centers. Make a point of warranty inclusion of components like drivers, modules, and surge protection so as to avoid incurring costs of downtime and repair bills in pallet operations. Regularly check seals, power supply connections, and control interfaces like 0-10V or smart integration modules to see if they are functioning properly. Partnering with vendors having good track records in food and beverage as well as refrigeration environments will ensure compliance with safety standards and performance. Suggested unused terms: pallet, aisle, energy efficiency and durability.

Demand for adaptable lighting: How can I integrate highbay lights with automation and control systems?

Highbay lights integration with warehouse automation and control systems would facilitate operations by synchronizing lighting with the operation of conveyors, forklifts, and pick-to-light systems, thus limiting energy use and maximizing productivity at the same time. Choose fixtures that give 0-10V, DALI, or networked modules as control options, and also ensure the power supply can handle the selected protocol and voltage ranges such as 120-277V. Besides, dynamic changes in illumination for narrow aisle and high-density storage along with advanced lighting scenes and occupancy sensing, can be combined to reduce costs of labor while enhancing safety standards. Proper integration planning should consider issues like EMI, surge protection, and the need for diffuse, glare-free lenses to ensure there is no interference with machine vision and barcode scanners. It’s very important to partner with integrators who have a proven track record in distribution centers and food processing plants as this will help maintain food safety, refrigeration performance, and sustainability in the long run. Suggested unused terms: SKU, narrow aisle