Aircraft hangars are not static places; they are constantly changing and thus require optimal lighting solutions to guarantee safety, efficiency, and accuracy. The right lighting conditions are essential no matter if it is for regular maintenance, aircraft inspections, or just general operations. At this point, UFO high bay lights really come to the rescue, powering and delivering energy-efficient light that is meant for large and expansive areas like hangars. But what actually gives these lights the preference, and how do they fit into the specific lighting needs of aircraft hangars? The post will open the most important considerations for hangar lighting, the benefits of UFO high bay lights, and how they can raise both the functionality and comfort levels in these important spaces.

Understanding High Bay Lighting

What are High Bay Lights?

High bay lights are an exclusive type of light fixture meant for places with towering ceilings that are usually between 15 and 40 feet or more. They are intended to give off powerful and uniform light over a vast area, thus being suitable for places such as factories, retail outlets, and large open spaces like warehouses, aircraft hangars, and production plants. These lights, to be honest, often make use of the latest technologies like LED whole system, which not only pumps out brilliant light but also guarantees energy saving and a long period of operation.

Key Insight: LED high bay lights have been the first choice for light fixtures because they consume less energy—up to 75% less than the old-fashioned lighting circuits—while still being as bright as and very low maintenance costs. Their practicality and endurance turn them into a significant part for every high-ceiling application where reliable and efficient lighting is the first priority.

Types of High Bay Lights

It is possible to find high bay lights in several types to fit different applications and to satisfy different preferences. Among the many types, the following are the most common ones:

LED High Bay Lights

The modern approach to lighting and the great energy-saving potential define LED high bay lights as the top option. They come with super brightness, low energy consumption, and less maintenance. the phrase “LED high bay lights” is getting more and more searched for mainly because of their great lifespan and versatility in terms of commercial and industrial environments.

Fluorescent High Bay Lights

Fluorescent high bay lights are still energy-efficient but not as much as LEDs; however, their low cost has made them popular among customers and they still are a good choice in terms of performance. These lights are mostly applied in places where the lighting demand is constant, and the need for an initial investment is low.

HID High Bay Lights

HID lights (high-intensity discharge) such as metal halide or high-pressure sodium lamps are the most luminous and one of the most powerful lighting types. However, their higher energy consumption coupled with shorter lifespan is among the main reasons that they are being replaced by LEDs gradually.

Induction High Bay Lights

The induction lighting technique, which is based on electromagnetic fields producing the light, offers superb longevity and efficiency. They are reputed for their long life span but are not as popular amongst the lighting applications today due to the advent of LED technology.

The right high bay fixture to pick is dependent upon such factors as energy consumption, budget, and the light requirements of the area being lit.

Benefits of LED High Bay Fixtures

LED high bay fixtures are quite beneficial and consequently, their demand in commercial and industrial sectors has increased significantly. Amongst all the advantages of these fixtures, their unparalleled energy efficiency is the greatest. Recent information indicates that LEDs require only one-fourth of the energy that is consumed by traditional lighting systems like metal halides. This consequently leads to huge reductions in the energy bills.

Key Benefits Summary

- Energy Efficiency: LEDs require only one-fourth of the energy consumed by traditional lighting systems

- Long Lifespan: Rated at 50,000 hours or more—up to 10 times longer than incandescent lights

- Instant Brightness: LEDs reach full brightness instantly with no warm-up time

- Reduced Maintenance: Significantly lower frequency and cost of replacements

- Eco-Friendly: No toxic compounds like mercury, lower carbon emissions

Moreover, high bay LED fixtures are eco-friendly and very safe for the environment, as they do not contain any toxic compounds like mercury and they are the least polluting regarding carbon dioxide emissions when compared to other types of lighting fixtures. Their solidness and ability to withstand changes in temperature extremes make them a perfect fit for areas that can range from the manufacturing floor to the warehouse to the sports stadium. When all these advantages are put together, LED high bay fixtures represent the future of lighting still in modern lighting solutions.

Lighting Requirements for Aircraft Hangars

Importance of Proper Lighting in Aircraft Hangars

Lighting in aircraft hangars is very important as it guarantees the safety, efficiency and accuracy of operations. Sufficient light lets maintenance staff notice and fix problems with aircraft, it also makes accidents less likely since the area is more visible and thus the overall workflow is better. Good lighting even more so causes eye fatigue to the workers on detailed jobs and at the same time fulfills the requirements set by the aviation industry. Not only do well lit areas make accidents less likely but also they cause accurate work to be done and skilled people to handle machines and tools properly.

Lighting Standards and Regulations

Aviation lighting standards and regulations are the safety barriers around hangar areas that ensure all activities are done in an efficient manner and compliance is maintained. These standards usually go hand in hand with the specifications set by organizations like the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA).

Key Requirements

- Sufficient light distributed evenly throughout the entire area

- Use of energy-efficient and durable systems

- Minimization of shadows and glare

- Adequate lighting for maintenance tasks under environmental and operational constraints

Factors Affecting Lighting Needs

There are several factors that are vital for determining the lighting requirements in the aviation maintenance areas. One of the principal factors is large storage space and good arrangement of sockets because huge places need better and more lighting installation. The nature of the work done is another important aspect determining the lighting’s strength and concentration; fine work requires higher light levels. Weather conditions, for instance, a cloudy day or night influences the amount of daylight coming in thus the need for artificial lighting during such conditions is increased.

Moreover, recent studies point to the breakthroughs in LED technology which feature longer lives, energy savings and lighting quality improvements that meet the maintenance requirements. searches show an increasing interest in the use of eco-friendly light source technologies as the industry seems to be prioritizing sustainable and cost-efficient solutions that do not compromise safety and accuracy.

Choosing the Right UFO LED High Bay Lights

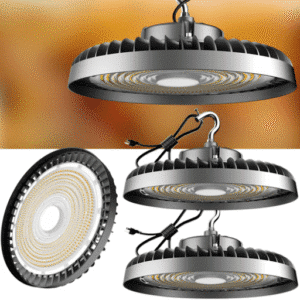

Features of UFO LED High Bay Lights

UFO LED High Bay Lights are extreme Halls of Fame, in which durability, energy efficiency, and performance were considered during the whole design process, thus being more than fitting for industrial and commercial applications. Lights with a new, compact, and disc-shaped design ensure that the entire area is covered with light evenly, making the light effect less intense and restricting the occurrence of glare. They consume a lot of energy but at the same time they are very efficient, so they are able to produce a strong light while being energy cost-effective.

UFO LED Features Checklist

- ✓ Compact, disc-shaped design for even light distribution

- ✓ High energy efficiency with strong light output

- ✓ Tough materials for long life cycles

- ✓ Ability to endure extreme conditions

- ✓ Dimming features available

- ✓ Motion detector compatibility

- ✓ Smart control integration options

Comparing UFO and Linear LED High Bays

UFO and Linear LED High Bays, the choice that needs to be made, according to the specific application requirements and the space’s layout will, of course, depend on a pros and cons list of these options. UFO LED High Bays are circular and are very strong and compact due to their robust design, so they can be installed at a larger height ceiling like those in places such as warehouses or factories. In this way, they can create light with wide circling beams, plus their installation will be an easy and fast process because they are in a single-point hanging design that is both lightweight and thus easy to lift and mount.

Buyers seem to have an increasing concern for energy-efficient solutions and expect the lights to be operating with smart controls and to have advanced features allowing great flexibilities within their preferences as searched phrases show. Ultimately, the decision between the two lighting types rests on a combination of factors including ceiling height, space layout, and various lighting application requirements.

Installation Considerations for High Bay Fixtures

Several key factors must be taken into account in order to ensure optimum performance and functionality when installing high bay fixtures. Firstly, the mounting height is of utmost importance as lighting in warehouses, factories, and gymnasiums is usually bright at heights of 15 ft or more, making them the best choice for history. To prevent dark spots and to achieve good light distribution over the entire area, the room’s layout should also be taken into consideration. Moreover, interoperability with the current wiring system is another important factor to consider in order to avoid difficulties in the installation process.

Installation Tips

- Consider mounting height (typically 15+ feet for optimal performance)

- Plan spacing to prevent dark spots and ensure even distribution

- Check compatibility with existing wiring systems

- Look for user-friendly features like hook mounts and quick-connect wiring

- Consider integration with smart control systems for automated operation

Optimal Lighting Design for Aircraft Hangars

Creating an Effective Lighting Layout

For a hangar, an effective lighting plan requires thorough consideration of the space’s specific needs, i.e., even illumination all over the area, glare very much reduced, and less energy consumed. Therefore, high bay LEDs are the best choice, as they are capable of dispersing light evenly and brightly to the entire area with high ceilings. Likewise, to ensure uniform light distribution, proper spacing and orientation of the fixtures are very important seeing to it that no dark spots are created in the process.

Best Practices for Hangar Lighting Design

- Even Illumination: Ensure uniform light distribution across the entire hangar floor

- Glare Reduction: Position fixtures to minimize glare and eye strain

- Energy Efficiency: Select LED fixtures for maximum energy savings

- Smart Controls: Implement automated adjustments based on occupancy or tasks

- Proper Spacing: Calculate optimal fixture placement to eliminate dark spots

Besides, the use of smart control systems could along with allowing automatic adjustments based on occupancy or certain tasks, could optimize energy usage. When the factors are set priority, lighting design could not only bring about great visibility but also safety and operational efficiency in the hangar.

Application of Various Lighting Solutions

In hangars, the application of various lighting solutions can effectively solve the problem of specific needs. LED lighting is the best choice because of its energy efficiency, long lifespan, and provision of bright and even lighting. High-intensity discharge (HID) lamps are another alternative, though they are less efficient than LEDs, their intense output is one of the reasons for their popularity in huge areas.

Task lights can be used in activities, such as inspecting and doing repairs, where accuracy is indispensable; therefore, lighting could not be more concentrated. Besides, smart lighting systems, which can adjust the brightness automatically, are also a good practice to reduce energy use and fit different conditions. When these solutions are joined together, the outcome is a brightly lit and energy-efficient setting.

Energy and Cost Evaluation

Energy efficiency along with cost-effectiveness, could be evaluated through taking into consideration the initial investment, the energy consumed, and the maintenance of different lighting solutions. LEDs, although they require a higher upfront investment, eventually offer a great savings through reduced energy consumption and also a longer lifespan. On the contrary, basic lighting such as incandescent and fluorescent might have a lesser startup cost but at the same time, they are energy-hungry and need to be replaced often, which leads to greater operational cost.

The integration of smart lighting systems not only enhances cost-effectiveness but also facilitates optimization of energy use by automated adjustments. Balancing these elements will lead to a daring and an economically sound lighting strategy in the area.

References

-

Life Safety and Fire Analysis-Aircraft Hangar

View Source

This document discusses the addition of high bay portions in hangars, including safety systems like sprinklers and lighting. -

Design Analysis of an Air Force Fuel Cell Maintenance Hangar

View Source

This analysis covers lighting requirements and emergency lighting considerations for aircraft hangar bays. -

The Level 2021-04

View Source

This document mentions energy-efficient LED lighting in large spaces, including hangars.

Frequently Asked Questions (FAQ)

-

How do led high bay lights perform in aircraft hangar lighting for hangar and aircraft hangars?

LED high bay lights are consistent in lumen output and can be defined in such a way, so that they will brighten the great airplane hangar spaces with the most favorable light distribution, thus increasing the visibility and safety. They have high efficiency compared to conventional high bay lights and fluorescent fixtures which means energy savings and lower maintenance costs. Dimming capability is a common feature in many led high bay lights for adjusting the level of light to the maintenance, inspections, or hangar operations, and the fixtures have been designed in a way that glare is minimized. In replacing the conventional lighting options, the lighting professionals advise taking into consideration the beam angle and the light output to be similar to existing lighting systems so as to lower the installation costs. Unused terms: linear high bay, free lighting, shop led high bay, round led high bays.

Advantages of linear led high bay light versus ufo led high bay light in the industrial sector?

Linear led high bay light fixtures usually offer more even illumination and are more convenient to lay out in rows for warehouse lighting or airplane hangar aisles, while ufo led high bay lights are smaller in size and are ideal for high-ceiling places. Linear high bay led options assist in having uniform lighting levels and excellent light spreading throughout large industrial areas, thus, no more dark spots and better performance in tasks. Both kinds of lamps reduce electric unit consumption and cost of operation greatly compared to traditional lighting, besides, many led high bay lights give more lumen output per watt. It’s ultimately a case of the bay width, mounting height and the required application beam angle that decides the choice. Unused terms: light quality, bay lights and linear led, surface-mounted, lights deliver.

How do lighting plans for commercial and industrial hangars address lighting requirements and lighting design?

Lighting plans determine the amount of light needed, the lumen output of fixtures, the beam angle, and the layout to provide light and safety across aircraft hangars and industrial areas. Experts emulate different lighting scenarios taking into account current lighting systems and whether fixtures are intended to be surface-mounted or suspended for best coverage. Proper application has also the consumption of energy as a factor, controls for dimming, and the high bay lights providing maintenance intervals that are consistent and longer life than fluorescent fixtures. The end result is a lighting solution that not only meets the prescribed lighting levels but also enhances operational efficiency. Unused terms: free lighting layout, led aircraft hangar lighting, industrial applications, lights can last.

Can high bay led lights help reduce energy consumption and provide maintenance benefits in airplane hangar settings?

High bay led lights are generally very energy-efficient and have very low maintenance costs because they consume little electric power and last longer than conventional high bay lights. Sometimes, industrial led systems come with already installed controls and sensors that help to save even more electricity by dimming or switching off the areas that are not being used or are getting enough light from the sun. High-quality led sources will not only lose less light over time but also offer a steady light quality that is fitting for inspection and safety in airplane hangars. All these advantages together mean fewer fixtures replacements and less downtime for taking care of the maintenance tasks, thus, the overhead costs are’nt affected. Unused terms: lights means, designed to illuminate, light source, lighting experts.

What considerations are important when retrofitting existing lighting systems with many led high bay lights in industrial lighting projects?

In the case of retrofitting, it is very important to investigate the existing lighting infrastructure, mounting heights, and electrical capacity to ensure that they are all compatible with the setting of many led high bay lights and also to achieve the desired light levels. Pay attention to lumen requirements, beam angle, and layout patterns—linear high bay configurations are different from round led high bays, and they influence the number of fixtures and the distance between mounting spots. Assess how much energy savings you will get, what rebates will be available, and whether controls for dimming or daylighting can be added to your current control system. Good planning with lighting experts leads to a retrofitting that improves light quality and visibility while causing little disruption to operations. Unused terms: high bay lights and linear, bay lights can be dimmed, quality led, industrial areas.

How do you choose the right high bay lights and linear led high fixtures to ensure optimal light distribution and visibility for maintenance and safety?

Select fixtures on the basis of required lumen output, mounting height, and desired beam angle so that optimal light distribution is reached all over the hangar floor and with no dark maintenance zones. For airplane hangar and industrial spaces, give priority to high bay led lights that maintain the highest light quality, can handle the toughest conditions, and are rated for top performance. Work hand in hand with the lighting experts to come up with plans that are not only compliant with the recommended lighting levels but also allow zoned control for different tasks, hence, improving visibility and safety at the same time. Lastly,