When it comes to energy efficiency in industrial and commercial spaces, lighting plays a significant role in operational costs. High bay lighting systems, commonly used in warehouses, factories, and large retail venues, are often notorious for their excessive energy consumption. Enter LED high bay lights—an innovative solution designed to drastically cut energy use while maintaining superior brightness and functionality. But just how much energy can they save? To provide a concrete answer, we’ve compiled real-world case studies that demonstrate the impressive energy-saving potential of LED high bay lighting. This post will explore the undeniable benefits of making the switch and present data-backed insights to help you make informed decisions for your lighting needs. Stay tuned for eye-opening examples that highlight both cost savings and environmental impact.

Understanding High Bay Lighting

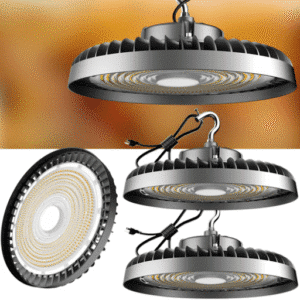

What Are High Bay Lights?

High bay lights are powerful fixtures designed to illuminate areas with high ceilings, typically ranging from 15 to 40 feet. These lights are commonly used in spaces such as warehouses, factories, gymnasiums, and large retail stores, where standard lighting solutions would fail to provide adequate brightness. Utilizing advanced optics and high lumens output, high bay lights ensure uniform lighting across wide areas, reducing shadows and enhancing visibility. LED high bay lights are becoming increasingly popular because of their energy efficiency, lower maintenance costs, and longer lifespan compared to traditional metal halide or fluorescent options. These benefits make them an essential choice for facilities focused on sustainability and cost-effectiveness.

Types of High Bay Lights

There are several types of high bay lights designed to suit different industrial and commercial requirements. The most common options include LED high bay lights, fluorescent high bay lights, and metal halide high bay lights. Among these, LED high bay lights stand out as the most energy-efficient and durable choice, offering up to 50,000 hours of lifespan while consuming significantly less electricity. Fluorescent options are a cost-effective alternative but require more frequent maintenance and replacement. Metal halide lights, though powerful, are less efficient and have a shorter lifespan compared to LEDs. Each type serves specific needs, but LED high bay lights are leading the way in popularity due to their superior performance and adaptability.

Benefits of Using High Bay LED Lights

High bay LED lights offer numerous advantages that make them an exceptional choice for industrial and commercial settings. Here are some of the key benefits:

Energy Efficiency

LED technology is highly energy-efficient, consuming up to 75% less electricity compared to conventional lighting such as metal halide or fluorescent bulbs. This results in significant cost savings on energy bills over time, making it a sustainable lighting option.

Long Lifespan

High bay LED lights are designed to last up to 50,000 hours or more, with some industrial models exceeding 100,000 hours of usage. This longevity reduces the need for frequent replacements and lowers maintenance costs, which is crucial in facilities with high ceilings and difficult-to-reach fixtures.

High Luminous Efficacy

LED high bay lights deliver bright, uniform illumination with a high luminous efficacy (measured in lumens per watt). Many models exceed 130 lumens per watt, providing better lighting quality while using less energy. This ensures improved visibility in warehouses, factories, and other large spaces.

Durability and Reliability

Built with robust materials and advanced designs, LED high bay lights are highly durable and resistant to shock, vibration, and harsh environmental conditions such as dust, humidity, and extreme temperatures. This makes them ideal for manufacturing plants and outdoor applications.

Better Lighting Quality

LED lights offer superior color rendering and adjustable color temperatures, providing light that mimics natural daylight. This improves visibility and reduces eye strain, leading to safer and more productive working environments.

Instant On/Off

Unlike fluorescent and metal halide lights, which require warm-up time, LED high bay lights turn on instantly at full brightness. This feature is particularly valuable in facilities where immediate lighting is essential.

Environmental Benefits

LED lights are eco-friendly as they do not contain harmful substances like mercury, which is commonly found in traditional fluorescent lighting. Additionally, their long lifespan and energy efficiency reduce waste and carbon emissions, supporting sustainability goals.

Cost-Effective Over Time

While the upfront cost of LEDs may be higher than traditional lighting, the savings from reduced energy consumption, lower maintenance, and fewer replacements make them a cost-effective choice in the long run. Facility owners and managers often see a full return on investment (ROI) within a few years.

By choosing high bay LED lights, businesses can enhance their lighting infrastructure while reducing costs and minimizing environmental impact—a win for both operations and sustainability efforts.

Energy Efficiency of LED High Bay Lights

Comparative Analysis: LED vs. Traditional Lighting

When comparing LED high bay lights to traditional lighting solutions such as metal halide or fluorescent lights, the advantages of LEDs become immediately evident. According to recent data, LED lights consume up to 75% less energy than traditional lighting systems. This significant reduction in energy usage translates to lower electricity bills and a decrease in carbon emissions, making LEDs an environmentally friendly choice.

Furthermore, LED lights boast an impressive lifespan of 50,000 to 100,000 hours, compared to metal halide bulbs, which last approximately 6,000 to 15,000 hours. This extended lifespan reduces the need for frequent replacements, thereby lowering maintenance costs over time. Additionally, LEDs provide consistent brightness without the warm-up time required by traditional lighting, offering efficiency and instant illumination in various settings.

Another critical advantage is heat output. Traditional lighting often dissipates a considerable amount of heat, leading to increased cooling requirements, especially in industrial facilities. LED high bay lights, on the other hand, produce minimal heat, improving overall energy efficiency and workplace safety. By switching to high bay LED lights, facilities can address operational challenges while benefiting from cutting-edge technology and substantial long-term savings.

| Feature | LED High Bay | Metal Halide | Fluorescent |

|---|---|---|---|

| Energy Consumption | 75% Less | High | Moderate |

| Lifespan (Hours) | 50,000 – 100,000 | 6,000 – 15,000 | 10,000 – 20,000 |

| Warm-Up Time | Instant | 5-10 Minutes | 1-2 Minutes |

| Heat Output | Minimal | High | Moderate |

| Maintenance Frequency | Very Low | High | Moderate |

Maximizing Energy Efficiency with LED High Bays

LED high bay lights maximize energy efficiency through a combination of advanced technology and superior design. Their lower energy consumption compared to traditional lighting systems significantly reduces electricity costs, while their minimal heat output decreases cooling demands in facilities. Additionally, LEDs offer longer lifespans, reducing maintenance expenses and operational disruptions. By upgrading to LED high bay lights, businesses can achieve sustainable energy goals, enhance workplace safety, and enjoy long-term savings, making them a practical and eco-friendly solution for modern industrial and commercial applications.

Long-term Energy Savings

LED lighting has established itself as one of the most energy-efficient technologies available, a fact supported by recent data from energy studies and resources. According to the U.S. Department of Energy, LED systems use at least 75% less energy and last 25 times longer than traditional incandescent lighting. This efficiency is further enhanced when paired with modern smart controls and automated systems, enabling businesses to adjust lighting based on occupancy and natural daylight levels. Additionally,Combining advanced LED technology with automation not only reduces energy consumption but also aligns with sustainability goals, providing both monetary and environmental benefits over the long term.

💡 Key Statistics: LED Energy Savings

- 75% – Reduction in energy consumption compared to traditional lighting

- 25x – Longer lifespan than incandescent lighting

- 50,000-100,000 hours – Average LED high bay lifespan

- 130+ lumens/watt – High luminous efficacy of modern LEDs

- 2-5 years – Typical ROI period for LED retrofits

Case Studies on Energy Savings

Real-world Examples of LED High Bay Implementation

📦 Logistics Company Warehouse Transformation

A prominent logistics company transitioned their warehouse facilities from traditional metal halide fixtures to advanced LED high bay lighting. Using occupancy sensors combined with automated dimming features, they reduced energy usage by over 60%. Search trends highlights that “warehouse LED solutions” searches have significantly increased in the last year, reflecting a growing interest in energy-efficient upgrades within the logistics sector. The combination of LEDs and automation allowed the company to lower maintenance costs and improve lighting performance, demonstrating the dual advantage of cost efficiency and operational improvement.

Results Achieved:

- 60%+ reduction in energy usage

- Significantly lower maintenance costs

- Improved lighting performance and visibility

- Enhanced operational efficiency

Manufacturing Facility Energy Overhaul

🏭 Large Manufacturing Plant LED Retrofit

A large manufacturing plant opted for an LED retrofit as part of their broader sustainability initiative. Real-time usage data revealed significant energy savings, cutting electricity consumption by 50%. Following this switch, productivity improved due to enhanced lighting quality, which reduced visual strain for workers. “LED high bay for manufacturing” queries have surged, indicating widespread recognition of the benefits in industrial environments. This case study underlines how LED high bays, paired with analytics and automation, directly answer growing demands for sustainable industrial solutions.

Results Achieved:

- 50% reduction in electricity consumption

- Improved worker productivity

- Reduced visual strain for employees

- Enhanced sustainability metrics

Quantifying Energy Savings in Different Industries

The adoption of LED high bay lighting has resulted in measurable energy savings across various sectors. For instance, in manufacturing environments, switching to LED systems has been shown to reduce energy consumption by up to 60% compared to traditional lighting solutions. Warehousing facilities also report significant reductions in operational costs, with some studies indicating annual savings of thousands of dollars per facility. Queries such as “energy-efficient lighting for warehouses” and “industrial LED savings” have seen a steady rise, reflecting the increasing interest in sustainable lighting technologies. These searches align with the broader industry trend toward energy efficiency and cost-effectiveness. By adopting LED high bay lighting, industries are not just cutting expenses but also significantly lowering their carbon footprints, contributing to global sustainability goals. This dual impact positions LED technology as an essential component of modern industrial energy strategies.

| Industry | Energy Savings | Annual Cost Reduction | ROI Period |

|---|---|---|---|

| Manufacturing | 50-60% | $15,000 – $30,000 | 2-3 years |

| Warehousing | 40-70% | $10,000 – $25,000 | 2-4 years |

| Retail (Large Stores) | 40-60% | $8,000 – $20,000 | 3-5 years |

| Sports Facilities | 45-65% | $12,000 – $28,000 | 2-4 years |

Impact on Energy Costs

It is evident that industries are increasingly turning to LED high bay lighting as a cost-saving measure. Search trends show a steady increase in queries related to energy-efficient lighting solutions, highlighting heightened awareness of energy costs. By replacing traditional lighting systems with LEDs, businesses can experience up to 75% reductions in energy consumption for lighting. This not only leads to significant financial savings but also aligns with corporate sustainability goals. The reduced energy demand also lessens the strain on power grids, contributing to greater energy stability and resilience on a broader scale. Such a shift underscores the critical role that LED technology plays in controlling and optimizing operational expenses.

Switching to LED High Bay Lights

Steps to Transition from Traditional Lighting Solutions

- Conduct an Energy Audit

Begin by assessing your current lighting system to determine energy consumption, lighting performance, and areas in need of improvement. An energy audit will help identify inefficiencies, potential savings, and the exact requirements for replacing traditional lighting solutions.

- Evaluate Lighting Needs

Consider the specific needs of your facility, such as brightness levels, color temperature, and coverage areas. For instance, warehouses, factories, and retail spaces may each require different levels of illumination and light distribution.

- Choose the Right LED Solution

Research available LED high bay lighting options and select products that meet your specific requirements. Look for LEDs with high energy efficiency ratings, long lifespans, and certifications such as DLC (DesignLights Consortium) or ENERGY STAR.

- Calculate ROI and Cost Implications

Use the latest data insights on energy savings to compare upfront costs with long-term savings. On average, LED technology can reduce energy use by up to 75%, resulting in quicker ROI for businesses transitioning to LEDs.

- Plan and Schedule Installation

Coordinate with an experienced lighting professional or team to strategically plan the installation process, causing minimal disruption to daily operations. Ensure all outdated equipment is safely removed while complying with local regulations for e-waste disposal.

- Train Staff and Monitor Performance

Common Challenges and Solutions

One common challenge when transitioning to LED high bay lights is the initial cost of installation. While LED systems can be expensive upfront, their long-term energy savings and lower maintenance costs often outweigh the initial investment. Another issue might involve resistance to change among staff unfamiliar with the new technology. This can be addressed through comprehensive training on the benefits and proper use of the LED lighting system. Additionally, occasional performance inconsistencies may arise, which can typically be resolved through regular monitoring and prompt maintenance to ensure the system operates at peak efficiency.

Choosing the Right High Bay LED Light

When choosing the right high bay LED light, it is essential to consider factors such as brightness, energy efficiency, and durability. Ensure the lumens provided by the LED light meet the lighting requirements of the space, while also prioritizing products with a high energy efficiency rating to lower operational costs. Durability is crucial, so look for robust designs with reliable heat dissipation systems to ensure longevity. Additionally, evaluate the compatibility of the light with your existing fixtures and consider features like dimmability if flexibility in lighting levels is important. By carefully assessing these factors, you can make an informed decision that suits your needs.

References

-

Naval Base Ventura County Energy Efficiency Program 2012

This program explores energy efficiency strategies for administrative buildings, highlighting co-benefits of integrating such measures.

Read more here -

Enhancing Efficiency and Sustainability: Retrofitting Fluorescent Lights to LEDs

This thesis examines the energy efficiency of retrofitting fluorescent lights with LED alternatives, emphasizing sustainability.

Read more here

References

How does comparison with traditional lighting show LED high bay energy savings?

LED high bay fixtures typically use 40–70% less energy compared with traditional lighting such as metal halide or high-pressure sodium, which directly reduces energy consumption and lowers utility bills. The light output from high bay leds is more efficient, so fewer fixtures or lower wattages can achieve the same illumination and improve the lighting setup. In many commercial and industrial spaces with high ceilings, the savings potential of high bay fixtures becomes substantial when considering ballast and maintenance differences. Lifecycle costs for led lighting solutions are usually lower because LED fixtures last longer and reduce replacement labor costs. Suggested unused terms: transition to high bay, linear led high bay, consumption of high bay led.

Can switching to high bay reduce energy and maintenance costs?

Yes, when you switch to high bay leds you not only save on energy through improved energy efficiency and longevity but also reduce maintenance frequency due to longer rated life compared with fluorescent lights. The reduced energy consumption of high bay led fixtures translates into measurable energy savings achieved by switching and a faster payback period for many projects. LED high bay lights offer more stable lumen output over time, which preserves illumination and energy efficiency and reduces the need for relamping. Operations managers often see reduced total cost of ownership in commercial lighting applications because LED fixtures require less downtime and fewer parts. Suggested unused terms: choice for energy savings, lights are built, high bay led lighting delivers.

Are ufo high bay led lights better for large warehouses than linear led high bay?

UFO high bay led lights are compact and provide a concentrated light output that suits high-ceiling spaces and retrofits where mounting height and aisle layouts favor focused illumination. Linear led high bay options often deliver more uniform illumination across aisles and can be preferable in racked warehouses or production lines for consistent lighting is the smart choice. Both types can enhance energy efficiency and longevity when compared to traditional lighting options, but the right lighting depends on ceiling height, fixture spacing, and desired light distribution. Comparing the consumption of high bay led types and modeling the lighting setup will reveal which offers the best energy savings and illumination for your space. Suggested unused terms: lights to traditional lighting, comparable led high bay, save on energy.

How much can commercial lighting save on energy after the transition to high bay?

Energy savings achieved by switching to led high bay fixtures commonly range from 40% to 70%, depending on the baseline traditional lighting and control strategies like dimming and occupancy sensors. For many commercial and industrial projects, the combination of high bay leds and controls yields substantial energy savings and improved lighting quality, which can further reduce operational costs. The savings potential of high bay installations increases when you replace older inefficient systems such as fluorescent lights or HID lamps that waste energy in ballasts and heat. Facilities often realize additional savings from reduced HVAC loads because LEDs produce less waste heat than traditional lighting. Suggested unused terms: light fixture, lighting is the smart choice, beyond energy savings.

Will high bay leds provide sufficient light output for spaces with high ceilings?

High bay leds are designed for spaces with high ceilings and can deliver higher lumen packages and controlled beam angles to meet required light output and uniformity. Fixtures like ufo high bay led lights or modular linear led high bay options can be selected based on mounting height and task needs to ensure adequate illumination and visual comfort. Photometric planning helps optimize fixture type and spacing so the lighting is effective while maximizing energy efficiency and longevity. In many cases, fewer high-output LED fixtures replace multiple traditional lamps while still enhancing energy efficiency but also improving color rendering and consistency. Suggested unused terms: led fixtures, lighting setup, save energy.

How do controls and sensors impact reducing energy costs with LED high bay installations?

Controls such as occupancy sensors, daylight harvesting, and zonal dimming significantly increase the energy savings achieved by switching to led high bay lights by reducing unnecessary run times and lowering wattage during unoccupied periods. Integrating smart controls with high bay leds amplifies the savings potential of high bay systems and allows facility managers to fine-tune schedules and scenes for different tasks. The combination of efficient lighting hardware and thoughtful controls can cut down on energy use and improve operating budgets across commercial and industrial sites. Over time, reduced runtime also extends the lifespan of LED fixtures, contributing to lower maintenance and replacement costs. Suggested unused terms: cut down on energy, energy savings and improved, achieve by switching to led.