Warehouse lights do the work of an integral force in setting operational parameters for safety, damage prevention, and functioning. The industrial lighting system has seen immense technological advancements, and among these systems, the number one pick by the sizable warehouse facilities must be UFO high bay lights, taking into account performance, energy efficiency, and longer lifespan. Built for massive spaces having high ceilings, these units provide superior luminosity to offer uniform illumination by reducing shadows for clearer vision. The article charts out the best UFO high bays for 2025 to be employed in warehouses and their characteristics, technological features, and energy-saving aspects, which will meanwhile benefit the operational efficiency. Be on these pages, reading this informative webpage, which would provide insights to make an educated decision whenever you are also into systemic updating or in creating a new setup.

Understanding High Bay Lighting

High bay lighting is typically designed for spaces whose ceilings are exceeding 20 feet in height. These types of lights provide a focused type of illumination that is much needed in big spaces, for example, in warehouses for companies, factories, or huge gymnasiums, where standard lights would hardly be able to give any adequately bright light. These fixtures are designed with the element of uniform distribution of light all over the different areas, resulting in a higher level of safety, increasing productivity, and improving operational efficiencies. The modern high bays, like their LED models, are very efficient energy-wise; other qualities allowing for optimal use in any contrasting types of environment settings include long usable life and maintenance-free little servicing over time, from time to time.

What are High Bays?

High bay lighting fixtures are designed for spaces with high ceilings, ranging from as low as 15 feet and above 40 feet. Application scenarios where these lights are meant to shine in all directions include industrial facilities, warehouses, manufacturing plants, gymnasiums, and other commercial settings. LED, fluorescent, or HID lights are suitable for this application, and LEDs continue to be preferred for their electricity cost savings, longer maintenance, heavier construction, and lower ability to draw energy consumption. Also, in the course of post-LED construction development, the design and the strong construction of these lights allow them to work well under challenging conditions: high temperature, dust, or vibration.

Importance of Choosing the Right Fixture

Selecting the best high bay lighting for high performance, energy savings, and maintenance in any area translates to greater returns. Best light can be functional for the illumination requirements of different spaces; focus on flexibility in the light intensity output, a color temperature that relates only to the envisioned environment, beam angle, and adapt it to the context of the linked spaces. Therefore, in case of a warehouse with tall ceiling height, lumens must be high while a narrow beam angle is recommended; a gymnasium would require a stiff light distribution in order to reduce glare. Moreover, for the fixtures situated in outdoor environments, their durability must be properly considered in terms of susceptibility to temperature fluctuations, moisture, or dusting, for reasons that will reduce the frequency of replacement and maintenance service. It is then through a crafty but judicious analysis of these factors that businesses have the potential to enhance productivity, ensure visual well-being, and ensure long-term operational efficiencies.

Types of High Bay Lights

High bay lights come in several forms, including those meant to be suited to different lighting requirement types and environmental conditions. Major types are high-pressure sodium, fluorescent, metal halide, and LED fixtures.

LED High Bay Lights

Preferred for their efficiency and longevity, LED high bay lights provide the brightness while consuming less energy. These are popular because they keep heat out of a fixture. In most cases, they would exceed 50,000 hours of life. They produce good illumination that is consistent and with a high CRI (Color Rendering Index). It can be operated with the option of being dimmed since it can support smart control processes, allowing for slightly larger maneuverability and greater cost savings.

Fluorescent High Bay Lights

T8 or T5 fluorescent tubes power these lights that boast great energy efficiency; their predecessors, like metal halides, could not achieve. These high bay fluorescent lights come with a fair rating of color rendering, are relatively friendly on the budget, and are great for use indoors in reasonable ambient air temperatures. However, they do not perform as well in cold conditions for long, and frequently need replacements due to shorter lifecycles compared to those in LEDs.

Metal Halide High Bay Lights

Metal halides are popular as they provide high-intensity lighting with good yet intense color rendering. They are less energy-efficient but can produce a lot of heat, which can significantly shorten their useful life, requiring more frequent replacement (usually after 6,000-15,000 hours). Slow warm-up time renders them less effective for quick illumination needs.

High-Pressure Sodium (HPS) High Bay Lights

Most people will use them mostly for industrial and warehouse lights. High-pressure sodium lights, or HPS lights, are also of low CRI, offering worse color rendering, everyday placed with LED lights for better efficiency and bright lighting.

Every type of high-bay light has its purposes as well as drawbacks, depending on what is required for your application–energy efficiency, which has to do with both cost and lighting quality, and environmental conditions.

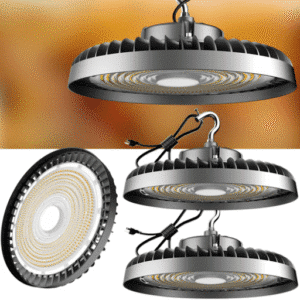

UFO High Bay Lights

Aptly named because of their small, round design, which may bear some likeness to a UFO’s shape, the high bay lights have long been in vogue owing to their efficiency in energy consumption, extreme durability, and satisfactory brightness. The lights are suitable for industrial and commercial applications. These lights come with LED technology and are comparatively lucrative as far as cost is concerned. The UFO high bay lights are able to perform perfectly well even in tougher environments, as they have been well-designed and optimized for thermal management. UFO high bay lights specifically and ideally cater to spaces, especially with a need for uniform lighting, such as warehouses, factory sheds, and gymnasiums.

What is a UFO High Bay Light?

A UFO high bay light refers to a specialized LED fixture intended for high-ceiling spaces, with homes height of 15 feet or more. Standing distinguished with its round and saucer-like appearance of a UFO, it emphasizes the maximum light dispersion and efficiency. These high bay lights are designed for greater illumination in many industrial, commercial, and institutional environments like warehouses, manufacturing, and gymnasiums. It has energy-efficient LED technology for UFO high bay lights, their longer service life, diminished maintenance requirements, and enhanced heat dissipation. The incorporation of a more amateur layout and tough construction subsequently guarantees their suitability in demanding environments. The result is a uniform delivery of light and constant functionality.

Benefits of UFO High Bay Lights

Energy Efficiency

Pertaining to advanced LED technology, the UFO high bay light consumes much less energy than conventional counterparts like metal halide and fluorescent lights. This leads to lower electrical costs while maintaining the best light illumination.

Lifetime at the Will

These lights have an operational run life of 50,000 hours and even more, and therefore, the replacements will be required less frequently, leading to a reduction of the maintenance costs over time.

Higher illumination and uniform light distribution

In terms of lumen output, UFO setups attain a higher spread to enable even light distribution to a large area, imparting brightness and uniform illumination for higher visibility and safety at workplaces.

Sturdiness and Reputability

With strong materials and cooling systems of any kind, the lights can withstand tough environmental demands, including hot temperatures, lots of dust, and moisture.

Fewer Maintenance

Less frequent maintenance and longer life are among the key reasons why UFO high bay lights have very little operational requirement, which may add interest and downtime or extra labour cost for their care.

Eco-Friendly

As far as carbon-producing resources are concerned, LED technology in UFO high bay lights has the advantages of no mercury content and significantly less carbon footprint, thereby resulting in environmentally friendly lighting for modern-day edifices.

Hence, our UFO high bay lights promise an extraordinary efficiency, bulb life, and the preservation of an eco-friendly atmosphere for tough industrial and commercial lighting needs.

How UFO High Bay Lights Compare to Other Types

UFO high bay lights have an edge over the traditional lighting prowess demonstrated by alternatives like Metal Halide, High-Pressure Sodium (HPS), or Fluorescent lighting in numerous aspects. Firstly, their lighting efficiency gives them additional layers of variegation. The UFO LEDs use much less power compared to other common systems like Metal Halide and HPS, significantly up to 75% less, providing the same or better level of performance in illumination. This also places them as a cheaper option for facilities with very high ceilings.

Secondly, longevity is a big advantage for UFO-LED high bay lights. Metal Halide bulbs, for instance, last for around 15,000 hours, fluorescent bulbs get up to 30,000 hours in life, while UFO LED may hold out to 50,000-100,000 hours before being programmed for artifact replacement. This lengthens life, reduces the frequency of maintenance surpluses and replacements, and incurs lower costs, not to mention the operational disruptions that such outages bring with them.

Finally, high-bay UFO lights provide a superior light quality. Unlike traditional HID light sources, ones that experience brightness and color shifts over time, LEDs maintain huge constant color accuracy, lumen maintenance, of color rendering index, and lighting reflectance and enhancing visibility. Such lights are used to improve safety and efficiency. An efficient LED system delivers 100 percent lighting output and higher-output-rated performance at the onset of powering up, or is operated by modernized smart-control systems.

LED High Bay Lights

The light option LED High Bay lights are ideal for illuminating vast spaces, such as warehouses, factories, and gymnasiums. They offer outstanding energy efficiency compared to traditional luminaires, helping in the reduction of skyrocketing power costs. Their power-saving capabilities generally mean a reduction in the maintenance outlay, thereby slashing their replacement frequency and unit expense. Still, they also come shining brightly yet smoothly without the patronizing glare, which ensures safety and productivity in your working environment. Pairing their integration with smart control systems provides better customization options, such as dimming and scheduling, which further optimize energy usage.

Advantages of LED High Bay Lights

LED high bay lights not only offer very bright illumination but also harbor very high CRI figures to ensure the perfect view and thus offer increased safety provisions in the workplace. The undiminishing illumination finds no shadow traces, thereby allowing for suitable area coverage, making ideal ergonomic conditions for the employees.

Enhanced control options-

A good number of LED high bay lights coalesce with the state-of-the-art intelligent control systems to be able to adjust the light according to the specific ratings, consumptions, and occupancy needs. These controls would guarantee further reduction in power consumption and provide for individual preferences.

Eco-Friendliness-

The destruction associated with their activities is averted. LEDs contain no harmful substances such as mercury and consequently emit almost no heat, rendering them good agents in respect of conservation. Their low power consumption suggests they reduce carbon footprints.

Integration of these features means even in cost terms, LED high bay lights are designed to be a holistic lighting solution and could pay off well for the smart developers of today’s sustainable facilities.

Best Practices for LED High Bay Installation

Proper light placement is important in achieving high performance, efficiency, and longevity of LED high-bay lights.

A few top best practices:

Appropriate placement in height

Based on the lighting area to be covered, choose the right mounting height according to the luminaire’s beam angle. For a minimum ceiling height of 15-20ft, medium beam angles must be selected while narrow beam angles need to be selected at higher elevations-20 to 40 feet-to adequately distribute light.

Spacing requirements

For even lighting, keep appropriate spacing between the fixtures. Place the lights at intervals that are proportional to the height of the ceiling to attain even lighting within the room, ensuring that excessive overlaying or shadowing is avoided.

Make sure the mounting is secure

Using good-quality mounting needs such as hooks, pendant adapters, or brackets compatible with the fixture and the ceiling structure. Supporting connections should be double-checked to obviate instances of accidents or undesired movements over time.

Ensure proper electric wiring

Obey and conform to all wiring codes and standards for the proper feeding of power and wiring compatibility requirements. Exclude the use of outlet bars and surge protectors to shield LED drivers from shockingly high electrical infractions or power-flux that could cause the LED system to fail after installation.

Dimming and Controls

Logically assume the installation of all dim and motion control systems meeting the lighting requirements for custom illumination.

Testing and Adjustments

Only test all installed products. Particular attention should be paid to beam alignment, brightness, and color temperature. Making any adjustments to further enhance the lighting for its intended application.

All these techniques will empower the facility to have an entirely maximized performance and durability of the LED high bay lighting system. Therefore, they provide a reliable and reasonable lighting solution that fits their operational needs.

Energy Efficiency and Cost Savings

LED high bay lighting systems are famous for their remarkable energy efficiency compared to traditional lighting appliances, such as metal halide or fluorescent fixtures. These often save a lot. That is up to 75 percent. This results in significantly lower utility bills. And the life span of one LED is much longer; typically, it exceeds 50,00 hours, leading to still more savings on maintenance and recoiling expenses over a longer span of time.

Diminished energy consumption and the welcome improvement with regard to the previously mentioned-retarded energy efficiency of the lamps have made these an economically good choice. Dimming and occupancy control also aid in enhancing energy-saving capabilities by only providing light when it is required. This merely enhances the rate of return after accounting for the government incentives or rebates for putting in LED lights alongside high bays.

In compliance with regulations, certain installations contribute money to cutting down on operational costs in environmental sustainability, limiting carbon emissions and energy demand. Per se, therefore, LED high bay lighting is virtually one of the most viable and eco-friendly propositions for significantly large lighting requirements.

Guide to Choosing the Best UFO High Bay Light

A refresh on the lumen output.

You should bear in mind that whatever the light source you choose for increasing the brightness in your place, the lumen supply has to match properly. The higher ceiling construction is usually expected to require some extra lumens to generate optimum light in the working area.

Save energy

In addition to recommending lights of high luminance efficacy, you will get your result in a high level of brightness, complying with the minimum input in terms of energy used.

Color Temperature

You will now choose the color temperature that would suit a particular setting: for example, in warehouses or any kind of industrial space, a color of 4000-5000K represents a degree of brightness very well and the daylight hue.

Durability

Now, an object constructed with durable materials such as diecast aluminum means it can be resistant to loading, dust, temperature variations, etc.

Certifications and Compliance

This ensures the goods fulfill industry-accepted standards. Examples include DLC Premium and UL listings, which guarantee dependable activity and security.

Warranty and Lifespan

With UFO high bay lights-extended warranties, and their operational life (50,000 hours and above) should serve you well for future happiness.

Key Features to Consider

Lumen Input and Efficacy

Prance over the UFO high bay light as it emits a huge and great amount of lumen output while providing smooth luminous efficacy per watt. Eventually, ensuring a higher quality of light with less energy consumption truly makes a difference within large playing fields.

Color Temperature Settings

Choose a fixture with adjustable or the right color temperatures measured in Kelvin so that it perfectly matches the needs of the environment. The range of 4,000-5,000K mostly occurs as the best for industrial or commercial zones since it delivers on the wisdom of warmth and brightness.

Durability and IP Ratings

Choose a configuration with the aluminum halos heat-sinking in an architectural grade. Check that a rubber gasket rated IP65 or better has been applied to the unit. This type of protection setup prevents issues with ingress by dust and water, bracing it up for a relentless environment like warehouses, gyms, or factories.

Dimmability and Compatibility with Intelligent Controls

The preordered UFO highbay lights, which are dimmable, should be a thing to search for, as they would allow for more energy savings and runtime adaptability. In the case of smart controls as well as motion, the settings may necessitate a link for a capacitive and effective provision of saving, usability, and quick issue resolution, pitched further toward automatable capacities.

Installer’s Benefits

Choose arrangements with easy means for mounting, such as hooks or stack shelves, as the lesser means seem most likely to promise a quick install and cost-effectiveness. Further pre-wiring or plug-and-play possibilities can greatly simplify set-up.

Focusing on the prime functions, these offer premium delivery, longevity, and adaptability to varied industrial or commercial lighting applications.

Top Brands and Models in 2025

While looking at the topmost industrial and commercial illumination brands for the year 2025, there are always three manufacturers that will come up again and again, owing to innovation, reliability, and higher technological advancement.

Philips Lighting-Signify

Philips, with its cutting-edge energy-saving lighting solutions, provides us a selection of LED luminaires formulated for performance while being adaptable on tracks. Standing out among them is the Interact Industrial Series, combining AMATA LEAP IoT capabilities, smart control, and environmentally sustainable design to considerable energy savings.

Cree Lighting

Cree holds a hand in designing exceptional products with high lumen output, longevity, and durability. The LS Series, engineered for industrial applications, especially for commercial applications, displays decent construction and excellent thermal management systems that ensure long-term stability and less maintenance.

GE Current (Daintree)

General Electric’s lighting division, Daintree, emphasizes some very bright ideas for intelligent solutions that have connections to smart facility networks. The Albeo High Bay LED Fixtures illuminate large areas in the best possible manner, possessing sensor functionalities for excellent automation and cost efficiency.

This is a brand that is leading the industrial and commercial lighting industry, and they offer products to meet growing demand for smart technology for energy savings while ensuring operational integrity.

Comparative Analysis of Different Fixtures

Performance Metrics for Industrial Lighting Fixtures

Among other critical performance determinants for the analysis of industrial lighting fixtures are some essential criteria: luminous efficacy (in lumens per watt), energy consumption, life, thermal management, and ability to integrate with smart systems. For instance, considering the Albeo High Bay LED Fixtures and some competitive models, glowing words are given for their record-high energy efficacy ratings and their ability to maintain light output, no matter the ambient conditions.

Integration with Smart Systems

IoT compatibility is now being constantly integrated into fixtures. In high-end models, we see motion sensors, daylight harvesting, wireless control, and other features that allow the fixture to actuate in response to environmental exposure. The Albeo High Bay LED Fixtures are a great example, where facility management platforms port in to control lighting schedules. Thus, the automation brought through the integration stands to prove really helpful for the cost savings.

Durability and Maintenance

Durability is a decisive factor defined via comparative reviews, with lighting fixtures receiving ratings according to impact resistance, ingress protectiveness (IP), etc., and rated up or down in relation to their thermal management systems. Most advanced lighting fixtures benefit from robust housing materials and thermally conductive technologies to enable their longer life in tough working conditions, as in warehouses or manufacturing plants.

Cost and Return on Investment (ROI)

Cost comparison reveals that premium lighting systems and fixtures may entail a higher first cost, but in the long term, these are very effective at conserving energy and reducing maintenance-related costs, thereby rendering a viable return-on-investment within a reasonable few years. The value for the users is in the total cost of ownership (TCO), which becomes their tool to exercise an informed purchase policy.

The best illumination system maximizes energy efficiency, smart functionality, and built-to-last components, and both adheres to the increasing industrial demands for sustainability and automation.

Best Practices for High Bay Lighting Maintenance

Regular Cleaning

The accumulation of dust and debris affects the light output of fixtures. Clean the lenses and surfaces at scheduled intervals with non-abrasives to retain the desired performance.

Checking of Components

Check components like wiring, connectors, and fixtures for signs of wear and tear. Addressing these issues should follow in a timely fashion in order to prevent malfunctioning in regular operations.

Replace Faulty or Aging Bulbs

Monitoring the LED or traditional bulbs’ lifespan becomes mandatory. Replacing these bulbs before the rated end of their lifetime maximizes the overall efficiency and brightness offered.

Verifying System Efficacy

A regular energy-use assessment should be made to ascertain the performance standards of various fixtures. This assessment can help to detect and rectify various inefficiencies and rental maintenance checklists.

Plan Preventive Maintenance

Put a maintenance schedule in place to ensure that fixtures and related systems have a longer service life with proper and professional upkeep.

Regular Maintenance Guidelines

Inspecting for Damage

A regular inspection of all fixtures for any physical damage like cracks, dents, corrosion, that can hinder functionality and overall safety. Any necessary repairs or replacements should be carried out without delay to prevent further problems.

Cleaning Fixtures and Lenses

Keeping fixtures clean, including the lenses and reflectors, maximizes light output and ensures dust does not accumulate and deteriorate performance over time. Follow the manufacturer’s recommendations when using appropriate cleaning agents.

Inspection of Wiring and Connections

Please inspect and confirm that all electrical wires and connections are securely fastened and free from wear and tear, and conform to all safety standards. Loose or frayed wires could result in system failures and dangerous working conditions.

Performance Metrics Testing

Light levels and system performance must be periodically tested to ensure proper functioning. Light meters and additional diagnostic tools are the means used to identify performance shortfalls and time-consuming inefficiencies.

Proactive Replacement of Components

If, over time, the parts begin to deteriorate slowly, such as ballasts, drivers, and bulbs, users should choose proactive means of maintenance and repair. The use of this practice curbs unplanned interruption of the lighting and ensures the systems work at full efficiency.

Together, these practices will help you maintain improved efficiency, safety, and longevity of the lighting system.

Identifying When to Replace Fixtures

I use specific indicators to decide when to replace the fixtures: repeated significant failures, exceptionally high energy utilization than modern alternatives, and declining light quality to the extent of affecting functioning and safety. Another experience shared with past decisions is that if the cost for repair is considerably more for repairing than for replacement, or if the fixture is quite outdated to support newer efficient technologies, then an up-to-date fixture may be the only practical and cost-effective approach.

Maximizing Lifespan of High Bay Lights

Ever since high bay lighting has been considered, prolongation seems to be the key objective in every context, and maintenance with inherent and precise orientations is the regular dictum. Periodic cleaning of the luminaries will sweep off all the dust and debris that gets accumulated on them, often responsible for the removal of the little performance they showcase once beyond the dust levels, overheating, or diminishing light output. On the other hand, ensure quality installation with good materials, plus all components are good with each other, necessitating inspection for how to avoid possible electrical or mechanical mishaps. A surge protector shall guard lights with regard to surging power and prevent them from failing older to any number of reasons. Operate these fixtures in temperatures and humidity ranges within the limits, as extreme weather of heat or moisture will accelerate the latter situation. At the same time, use energy-saving LED lights in place of traditional lights, as the first variety can even have a life more than twice that of traditional ones, with hardly a fraction of the power consumption. This way, you will guarantee a longer operation period for your use of high bay lights, consistent of consistency, and much lesser overall costs.

Reference Sources

Frequently Asked Questions (FAQs)

High bay LED lights: What are the differences between the existing high bay LED designs, and how will I decide which one I need out of them?

Some designs for high bay LED lights are UFO [small round], linear, and modular series high bay light fixtures. It can depend on the ceiling height, bay spacing, and work required. Remember, UFO models are small and powerful, acting as products for general lighting. Regarding Linear high bays, these may cover aisles and workbenches in the factory. At the same time, the series may be applied for high-intensity lighting applications above manufacturing lines, and thus you are to select the one that best suits your needs.

light fixture: How do LED high bay light fixtures improve safety and productivity in warehouses?

LED high bay light fixtures significantly boost safety and increase productivity by delivering consistent, flicker-free illumination that ensures even diffusion of light and an accurate rendering of colors, which minimizes eye fatigue and enhances visibility. In a large commercial space with very high ceilings, the use of LED high bay fixtures over metal halide lamps and traditional lighting solutions may also decrease downtime as a result of lamp changes and significantly cut energy costs while improving working light levels.

LED high bay light fixtures: What differentiates Series High Bay and Halo Series High Bay Light options from one another?

Designs of series high bay or series high bay light normally mean modular fixtures that can be added to or daisy-chained along longer runways or continuous rows. In contrast to UFO lights, series designs perform exceedingly well in linear configurations, such as production lines, and have impressively even light distribution for long spans: perfect for industrial or commercial purposes, especially when the pros are good uniform lighting delivery across the entire floor area.

UFO lights: Can UFO lights replace linear high bay and traditional lighting solutions?

UFO lights can replace many traditional lighting options, such as metal halide lights, but whether they should replace linear high bay lights depends on the application. UFO high bay LED lights have the power as well as a compact design that is perfect for lighting up big, wide-open bays and high-demand ceiling construction. Linear high bay or LED shop lights could be better for aisles, racking installations, or workbenches. So the right setup ensures the lights are best suited for their settings.