Selecting the correct high bay light for a warehouse is a decision that greatly influences not only the visibility aspect but also the energy efficiency, productivity, and safety standards in the warehouse. The market is flooded with various options like LED technology, different lumen outputs, and beam angles, making it daunting to find the perfect lighting solution. This detailed guide aims to clear up that confusion and present you with the technical knowledge and practical factors to consider for making a good choice. Be it replacement of a former system or setting up a new one, you will identify the most important factors regarding, for instance, energy consumption, ceiling height, and light distribution, for ensuring your warehouse is functioning at its best.

Understanding High Bays

High bay lights are types of lights that are specially made for places with high ceilings, which are usually 20 to 40 feet high. Such lights are capable of giving the large areas, where they are used, uniform and very bright light that is necessary in places like warehouses, factories, and gymnasiums. Their design guarantees that a lot of light would be reaching the surface, so there would not be much shadow, and the visibility would be better. High bay lights have different kinds of lights, such as LED, fluorescent, and HID lighting, that can meet different requirements, providing a good combination of energy-saving, long life, and good performance.

What are High Bay Lights?

High bay lights are very bright and strong lighting fixtures meant for areas with high ceilings, generally of over 20 feet. They are often used in factories and commercial places such as warehouses, manufacturing facilities, sports arenas, and large retail stores where the quality and safety of lighting are very important. These lights provide regular light distribution, lessen glare and shadows, which are strong points of large-scale lighting. Contemporary high bay lights, especially LED ones, have become more energy-efficient, have a longer life span, and require less maintenance, making them a very affordable option when compared to traditional fluorescent or HID fixtures.

Types of High Bay Lights

The high bay lights division is based on their design, light source, and application. The major classes are as follows:

LED High Bay Lights

LED high bay lights are the latest and most energy-efficient option. They convert electrical energy to light with minimum loss so that their lumen/watt ratio is the highest. Besides, LEDs have a long life (over 50,000 hours often) and produce very little heat; therefore, they are mainly used in industrial and commercial areas. LED lights come in different forms, such as round (UFO) or linear configurations, depending on the layout.

Fluorescent High Bay Lights

Fluorescent high bay lights’ ability to deliver reasonable performance at a low price was the main reason for their widespread use in the past. Large fixtures use T5 or T8 fluorescent tubes to provide a good quality and uniform light over a large area. Nevertheless, maintenance of these lights needs to be performed more often than that of LEDs, and they do not return the best energy efficiency when compared to LEDs in the long run.

HID (High-Intensity Discharge) High Bay Lights

HID high bay lights include metal halide and high-pressure sodium that produce the most powerful and intense light output. Historically, they were intended for warehouses and arenas but have so many drawbacks, like long warm-up time, high heat generation, and shorter life span than LED, which all add up, making them inefficient in today’s applications.

When choosing a high bay light type, the important factors of energy efficiency, maintenance requirements, and the unique characteristics of the space should all be taken into serious consideration.

Benefits of Using High Bay LED Lights

Heavy-duty LED fixtures, long-lasting and energy-efficient lights, that eventually lost out on the market. Their primary energy-saving feature is a big acceptance that makes them even more popular in industrial and commercial applications. They consume very little energy compared with traditional lighting systems, such as metal halide or fluorescent ones, thus resulting in huge energy bill savings in the long run. Besides, very little heat is generated by LEDs, which contributes to the lessening of stress on the air-conditioning systems, and this also energizes the whole plant to be more efficient in energy use.

Another major plus is their lifetime, which is nothing short of amazing. LED high bay lights are known to last for not less than 50,000 hours, which is a huge leap compared to the life span of metal halide lights, which need frequent replacements. Thus, the changes in the lighting that are done often do not happen very quickly. Besides that, such longevity grants the maintenance being done and the related costs in high-ceiling areas where access is often difficult and costly. Consequently, this technology is not limited to the maintenance factor.

On the other hand, LED lights have always been the best as to lighting quality. They give brighter, even, and higher Color Rendering Index (CRI) lighting, thus increasing visibility and safety in critical areas like warehouses or manufacturing plants. Taking into account the fact that their warm-up time is none, it is guaranteed that their performance would be optimal without any delay.

Finally, it is hard to deny the sustainability factor that high bay LED lights provide. They are the greenest lighting that has ever been invented since there is no toxic waste involved in the production of the lights, and after their use, eventually, the waste that is generated is less due to their longer life. The light that is produced by the high bay LEDs is always the best, so that in the modern era of lighting, where efficiency, performance, and environmental impact are key determinants, they have no other option but to be the lighting solution.

Warehouse Lighting Options

When it comes to lighting a warehouse, high bay LED lights are the winner in terms of efficiency and reliability. They are the best eco-friendly option among all lighting sources, as they use less power and generate less heat than HIDs while achieving the same brightness. Besides, they have a setup that allows for even light distribution and thus makes it possible to work safely and productively with minimal maintenance. Their flexibility allows them to perfectly fit into different warehouse designs and heights, and lighting needs. Therefore, high bay LED lights are the best choice for operations that want a solution that is both economical and environmentally friendly.

Choosing the Right Warehouse Lighting Fixtures

Choosing suitable warehouse lighting fixtures is a multi-faceted critical factors assessment to ensure that the lighting system would have the best performance, the least energy consumption, and also be the most cost-efficient. First of all, take into consideration the height of the warehouse ceilings, since high bay LED lights are meant exactly for ceilings of more than 20 feet, thus giving the very large areas even illumination. After that, examine the layout and purpose of the warehouse. To illustrate, the task-specific areas might need high CRI (Color Rendering Index) lights for accurate visibility, while the general storage area might be okay with low-intensity fixtures.

Energy efficiency is a major factor as well, since LEDs are the winners in this aspect by providing more lumens per watt than traditional lights, which results in a considerable decrease in electricity consumption. Furthermore, make sure that the fixtures are equipped with suitable dimming options or motion detectors to get even more energy reduction. Durability is also a concern; therefore, go for the lights that possess high IP (Ingress Protection) ratings, as that means they are able to withstand dust, moisture, and even the damage caused by accidental impacts.

Finally, keep in mind possible future improvements like the installation of smart lighting systems that will work together with the warehouse management technologies. Such systems can provide sophisticated controls, including scheduling and adaptive brightness, which will not only improve the functionality but also increase productivity. By taking into account the above-mentioned factors, companies can find a very good compromise between the cost, performance, and sustainability of their lighting systems.

Comparing LED High Bays and Traditional Fixtures

When it comes to the comparison between LED high bay lighting and traditional lighting fixtures like metal halide and fluorescent systems, there are several factors that need to be considered. LED high bays are remarkably energy-efficient, often using only 20-50% of the power of their traditional counterparts while providing the same or even higher brightness levels. The energy costs incurred will, however, be significantly less over the years because of this efficiency.

An additional benefit of LED high bays is that they last much longer. LEDs offer a lifespan of 50,000 to 100,000 hours, while metal halide or fluorescent lamps typically last 10,000 to 30,000 hours at most and consequently are subject to more frequent replacements. This exceptional lifespan allows for fewer maintenance requirements and, as a result, lower labor costs.

LED fixtures also boast of light quality and performance. They yield flat and very high-quality light without flickering, are capable of instant on/off, and have good color rendering; all these to the extent that prompt detection and safety in warehouse areas have been proven. Conversely, a longer warm-up time, lower color accuracy, and light degradation are some of the problems that usually characterize the situation with traditional fixtures.

Besides, LEDs have a better impact on the environment. They do not use any toxic substances, such as mercury, which is commonly found in fluorescent lamps, and they emit less heat, thus making them safer and cutting down on the cost of cooling. The upfront cost of the LED high bay lighting may be significant, but the total cost of ownership is usually less because of energy savings, longevity, and maintenance requirements being lower.

On the other hand, traditional lighting systems may still be considered if the business goal is to achieve cost-effective, reliable, and sustainable lighting. In that case, the traditional lighting systems will be compared and even assessed with LED high bays, with the major consideration for the latter being the superior choice.

Energy Efficiency in Warehouse Lighting

Energy efficiency in warehouse lighting has a major impact on the operating costs and the sustainability of the warehouse. As the most energy-efficient lighting technology, LED lights can save up to 75% of the energy consumption compared to the standard fluorescent and metal-halide systems. The difference in energy usage comes from the LEDs’ capability to produce more light and less heat simultaneously, which results in overall lower electricity consumption. Furthermore, LED lights come with smart controls that can automatically switch on or off the lights in certain areas if there are no people present or if the lights are not needed.

Moreover, the facilities that can replace their old lighting systems with LEDs stand to gain the most from this technology, as the latter has an extremely long life cycle of about 50,000 hours or more, thus greatly reducing the frequency and costs of maintenance. Switching to LEDs not only provides instant energy savings but also leads to less carbon dioxide emissions, and thus to the realization of more extensive environmental objectives. When planning lighting upgrades, it is essential to assess various factors like lumen output, beam angles, fixture placement, and compliance with energy codes to guarantee that warehouse spaces are perfectly efficient and effective.

Lighting Design for Warehouses

- Energy Efficiency: Adopt LED lamps for their excellent energy savings, lengthy lifetime, and less frequent need for upkeep compared with conventional light sources. Besides, LEDs fit well with the eco-friendliness agenda by cutting down energy use and carbon emissions.

- Illumination Levels: Verify that an adequate lumen output is provided for the proper operation of the warehouse. Generally, the areas should receive a light distribution of 200–300 lux and a totally even distribution of light, while specific tasks might need stronger lighting.

- Fixture Placement: Place lights wisely so that shadows and dark areas are very few. High-bay lighting fixtures work well for distribution centers with high ceilings since they provide even lighting over large areas.

- Safety and Compliance: Observe local energy regulations, safety standards, and codes of practice, as this will not only protect your workers but also operate the business more efficiently. This should include the efficient incorporation of emergency lighting systems.

- Lighting Controls: Connect automatic controls like motion detectors and timers to the lighting system so that energy consumption is slashed in areas with little or no traffic, which will, in turn, result in more optimized costs of operations.

The implementation of these elements will lead to the development of warehouse lighting systems that are effective, sustainable, and cost-efficient while at the same time enhancing visibility, safety, and general productivity.

Lighting Layout Considerations

A systematic strategy that guarantees the best possible lighting, energy saving, and operational effectiveness is required for a warehouse with an effective lighting layout to be designed.

- Lighting Uniformity: The workspace’s lighting levels must be consistent throughout the area to prevent the formation of shadows and dark spots that could lead to accidents and the consequent loss of productivity, in addition to the latter. Uniformity can also be achieved through the proper mounting height and regular intervals for the fixtures’ placement.

- Task-Specific Lighting: It is necessary to locate places where more light is needed, like loading docks, inspection stations, or packing zones. In these areas, task lighting should be specifically designed and installed, buried under the general workspace lighting that will just allow moving around the place.

- Energy Efficiency and Lamp Types: Apply the energy-efficient light sources like LED lighting that offer higher lumens output per watt. LED bulbs are also maintenance-free for a longer time than traditional metal halide or fluorescent lights, owing to their longer lifespan.

- Ceiling Height and Light Distribution: The ceiling height must be calculated accurately to find the corresponding fixtures and optics. Fixtures meant for high ceilings are usually recommended for more than 20 feet and aimed at preventing light from pooling in one part of the facility.

- Photometric Analysis: Perform a detailed photometric analysis to visualize light levels in the warehouse, confirming compliance with the standards set by OSHA or IES for the best brightness and safety.

- Zoning and Controls: The zoning feature that divides the warehouse into sections for separate lighting control should be utilized. The use of daylight sensors, motion detectors, or programmable timers to automate these zones will cut down the energy usage in areas with infrequent activities.

Considering all these factors, the lighting designs of warehouses will be able to provide the highest efficiency, safety, and compliance with regulations, thereby making an environment that is best suited for both employees and operations.

Light Distribution Techniques

A well-planned light distribution in a warehouse setting has to take into account uniformity, efficiency, and flexibility. The main objective, however, is to make sure that all parts of the building receive enough light so that shadows are eliminated, visibility is improved, and the safety of the workers is enhanced without much energy consumption.

- Uniform Illumination: Wide-angle LED fixtures or high bay lamps should be used to provide a constant light level throughout the vast space. Uniformity does away with dark patches that might hinder the flow of operations or even endanger lives.

- Beam Angle Selection: Beam angles need to be posed according to the height of the ceiling and the configuration of the area. For high ceilings, narrow beams are perfect as they concentrate the light on the particular task, while broad beams are the best choice for low ceilings and they spread the light evenly.

- Task-Specific Lighting: Include task lighting in the warehouse to light up the areas that require utmost precision, like the inspection zones or the detailed assembly stations. The use of adjustable fixtures allows for flexibility with the lighting according to the needs of the operation.

- Reflective Surfaces: Light efficiency can be significantly improved by using reflective surfaces, for example, light-colored ceilings and walls, to distribute light better and lower the number of fixtures needed.

- Integrated Controls for Light Optimization: To maintain the same level of light while using less energy, install daylight harvesting systems and motion-activated fixtures that will adjust lighting according to the number of people present and the amount of natural light coming in.

The application of these methods will result in a very effective lighting setup for the warehouses that is specifically made according to their operational requirements, thus contributing to not only increased productivity and energy savings but also the overall safety of the place.

Best Practices for High Bay Lighting Design

- Assess the Lighting Needs: Perform a detailed and meticulous examination of the building’s design, height of the ceiling, and daily activities to calculate the necessary lumen output. This guarantees lighting that is evenly distributed in the most suitable way for the environment.

- Choose the Right Fixtures: Go for LED high bay lights since they are the most energy-efficient option and have the longest lifespan. Over time, they will be your best choice in terms of light quality and consumption, which is less than HID or fluorescent systems.

- Use Reflectors and Optics: Use aluminum reflectors when you need very concentrated light downwards, or for wide dispersal, acrylic reflectors. The lensed fittings not only increase the light output in some areas but also ensure the same light density in other corners or less-used spaces.

- Adopt Dimmable and Smart Controls: Dimming features and intelligent lighting systems should be part of the design to fit the lighting to immediate needs. It reduces the energy loss incident to perfect lighting levels while the space is occupied, and even with the light coming from outside.

- Consider Color Temperature and CRI (Color Rendering Index): The target color temperature (e.g., 4000K-5000K) for each work area should be chosen wisely. The high CRI (>80) makes visual quality better, and thus, it is a safe place to work.

- Plan for Maintenance Accessibility: Maintenance and replacements should be done with fixtures that are easy to access. This cuts the downtime and ensures uninterrupted operation in critical zones.

By following these recommendations, high bay lighting design will not only be able to satisfy the users’ expectations but also make a significant impact on saving energy, providing safety in the workplace, and enhancing productivity overall.

Specific Types of LED High Bay Lights

Linear LED High Bay Lights

Available for large, open areas like warehouses and assembly lines, these lights produce wide and uniform light over rectangular spaces.

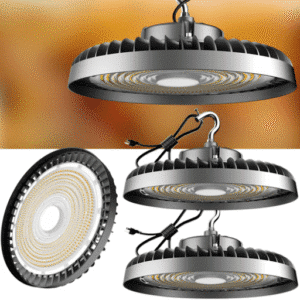

Round (UFO) LED High Bay Lights

Small and superbly efficient, these lights are apt for places with very high ceilings, such as gymnasiums and factories, and provide sharp and strong lighting.

Integrated LED High Bay Lights

The most advanced and performing fixtures incorporate the light source and the housing for the highest maintenance and replacement savings.

Motion Sensor LED High Bay Lights

These lights operate through sensors, which greatly reduce energy use by turning themselves on only when someone is around; thus, they are perfect for areas with changing populations.

Each type not only meets but also accommodates the specific requirements for the different functional and operational slots, thus providing maximum efficiency and adaptability through the different applications.

UFO High Bay Lights

UFO High Bay Lights are a lighting solution that boasts great energy efficiency and versatility, and they are mainly found in industrial and commercial spaces having high ceilings of about 15 to 40 feet. The circular, compact shape of these lights is a plus because it leads to an even light distribution over a vast area, sometimes called ‘good luminous intensity’, and also assists in the dispersal of heat. Usually, these lights are made to last with materials that can fight even the harshest conditions, like aluminum; thus, they are used in places like warehouses, factories, gymnasiums, and retail stores.

The main pros include lower energy consumption; most models use LED technology, thus the energy reduction compared to conventional metal halide or fluorescent fixtures. Besides being energy efficient, they have a long life span, very often above 50,000 hours, which leads to savings in maintenance costs. Many fixtures come with dimmable options or smart controls, allowing the client to further customize the solution to his or her needs by choosing the right lighting level, thus maximizing the efficiency of the operations. Besides, the lightweight design and the mounting hooks or brackets provided in the package make the installation quick and easy.

UFO High Bay Lights come with a selection of color temperature options that can go from 4000K to 6000K; the latter being the most common one, and the former provides light that is clear and bright enough for areas with high visual clarity requirements. Their versatility, along with the performance aspect, is what makes them an indispensable choice in the spectrum of modern high bay lighting solutions.

Linear High Bay Fixtures

Linear High Bay Fixtures are specifically made to give out even and effective lighting in vast indoor areas like warehouses, factories, and commercial buildings. Unlike UFO High Bay Lights, which are round and compact, these fixtures have a flat and long rectangular design that guarantees wide coverage and very little shadowing, which makes them perfect for aisles or totally open areas. They usually come with state-of-the-art LED technology that provides great lumen output and consumes very little energy, thus resulting in a huge reduction of operational costs.

Different lengths are offered, like 2 feet or 4 feet for the Linear High Bay Fixtures, and various mounting ways, such as chain, pendant, or surface mounting, are also available so that the fixtures fit different ceiling heights and layouts. The fixtures are made out of strong materials like aluminum that take good care of heat and are lifetime even in tough conditions. The Linear High Bays provide different color temperature options (4000K, 5000K, and even more) for the lighting that is most suitable for the kinds of tasks that need visibility and precision. The use of motion sensors and dimming functions further leads to energy efficiency and lighting control so that these fixtures can be recognized as a flexible solution for both industrial and commercial applications.

Choosing Between UFO and Linear LED High Bays

UFO and Linear LED High Bays are not only the two most distinguished types of high-bay lights, but also the choice of one over the other would significantly depend on the nature of the application and the space layout. The UFO LED High Bays have a compact and circular design, which characterizes their adaptability to the high-ceilinged and wide-open spaces that are typical of warehouses, gymnasiums, and factories. They produce a highly concentrated beam angle, which allows them to be the best lighting solution over the larger vertical distances of the areas mentioned above.

In contrast, Linear LED High Bays are the most appropriate lighting solution for those spaces that have a layout like the aisles in supermarkets, such as retail stores, workshops, and storage facilities. Their long design guarantees that light will be evenly distributed over the rows of shelving, thus avoiding dark spots and making the area more visible. Besides, Linear High Bays frequently enable an easier upgrade in places where old fluorescent fixtures are in use, thus providing a smooth transition to a modern lighting system.

Both types of lights boast efficient power usage, longevity, and the ability to work with state-of-the-art features like motion detectors and control over brightness. Considering factors like ceiling height, room layout, as well as light coverage will guide you in making the right choice for your particular lighting requirement.

Implementing LED Warehouse Lighting Solutions

LED lighting is the best option when it comes to energy efficiency and lower operational costs as it is compared to Traditional lighting systems. It does provide uniform quality light, which is very bright and enhances visibility and safety in the warehouse areas. LEDs also with longer lives, which means maintenance is less often needed and operational disruptions a minimized. And for the best performance, use features like a motion sensor and dimmer controls to adjust the light according to the use and the people present.

Steps to Transition to LED Warehouse Lighting

- Assess Current Lighting System

Conduct an all-inclusive examination of your present lighting system to reveal the number, kind, and quality of your lighting fixtures. Keep track of the power usage and give a report on the lighting performance in the warehouse according to the different areas. - Define Lighting Requirements

Determine the exact light requirements for different activities and areas inside the warehouse. Decide on the factors like brightness in lux, color temperature, and light direction to give sufficient light for actions like storage, packing, and unloading. - Calculate Potential Savings

Evaluate the advantages in terms of electricity and money that could be achieved by the change to the use of LED lighting. Calculate your return on investment (ROI) by factors like lowering of wattage, the efficiency in energy usage, and the lower number of replacements needed. - Select Suitable LED Products

Pick LED lights that are long-lasting, high-efficiency, and meet the specific lighting demand of the warehouse. Go for the ones with high lumen output, the proper IP ratings for protection against dust or moisture, and the necessary certifications for reliability and safety. - Plan Installation and Layout

Create a lighting plan that is not only the best for coverage but also the least for shadows and glare. Work with lighting pros or engineers to find the best places for the lights to get the most efficiency. - Integrate Smart Lighting Controls

Add modern control systems such as occupancy sensors, daylight harvesting, and programmable dimmers. These capabilities reduce energy use by changing lighting levels according to real-time activity and the condition of the environment. - Execute Installation

Work with competent electricians or contractors to make sure the LED system is installed correctly. Make sure all the lights and controls are installed properly and working before completing the switch. - Monitor and Evaluate Performance

After the installation has taken place, observe the system’s performance for a while. Use data from energy consumption and comments from employees to quantify the improvements in cost savings, lighting quality, and overall efficiency. Make alterations in settings if necessary to ensure continued optimization.

Evaluating Lighting Performance and Efficiency

When it comes to lighting performance and efficiency evaluation, I employ a combination of qualitative and quantitative metrics. I look at the data related to energy consumption in a way that shows visible savings and efficiency gains, then I proceed to take people’s inputs to confirm that the light is designed according to their requirements. Moreover, I keep an eye on the system’s performance for a long time, and if necessary, I adjust the settings or the arrangement to keep the functionality and effectiveness at the optimal level. The method guarantees a compromise between energy efficiency and excellent lighting results.

Future Trends in High Bay Lighting Technology

The evolution of high bay lighting technology is being enacted mostly through advances in energy efficiency, smart controls, and sustainability. One of the most considerable trends is the blending of smart lighting systems with IoT (Internet of Things) capabilities. These systems render features such as automated dimming, occupancy sensing, and remote monitoring, which together give real-time control and energy optimization.

Tunable lighting and human-centric designs are among the new trends gaining momentum. These new approaches help to adjust the light color temperatures in space according to people’s circadian rhythms, which in turn makes the work environment more comfortable and productive and increases the overall well-being. Moreover, innovations in LED technology are still ongoing, and these not only maintain the high quality with regard to lumen output, lifespan, and energy efficiency, but also lower the maintenance costs.

The above-mentioned developments are polluting America less and less each year, as the manufacturers provide eco-friendly materials, recyclable components, and renewable energy source integration for their systems. These advancements will solve environmental issues as well as comply with strict energy regulations and building standards, thus making them part of the future of high bay lighting solutions.

Reference Sources

Warehouses Walk the Green Talk

Analysing Fire Risk in Automated High Bay Warehouses

Optimum design of retail and wholesale buildings for minimum energy consumption and total cost

Frequently Asked Questions (FAQs)

How do LEDs compare with conventional lighting in terms of warehouse lighting?

LEDs provide a quality LED high bay alternative that outperforms traditional lighting options in efficiency, lifespan, and controllability. In a warehouse or other large space, LEDs reduce energy use and heat output, meaning lower utility costs and improved working conditions. When comparing LED lighting solutions to traditional lighting solutions, consider long-term ROI, reduced maintenance, and the ability to integrate controls and dimming for a professional lighting project.

Which is the best lighting solution for high bay environments: round high bay or linear high bay LED?

The best lighting depends on your layout and tasks. Round LED high bay lights, including round high bay or round UFO high bay, are ideal for concentrated point-source lighting over aisles or single machines. Linear high bay lights and linear high bay LED fixtures, including LED linear high bay and linear high bay lights, work well for continuous runs, racking, and general ceiling lights. A lighting guide or professional lighting designer can recommend the most efficient combination for your warehouse to become more productive with the right layout.

What are the benefits of LED high bay lighting fixtures for a warehouse or facility?

High bay LED lighting fixtures offer numerous benefits of LED technology, including long life, energy savings, instant on, and low maintenance. Benefits of high bay LED include improved color rendering, reduced glare, and compatibility with sensors and controls, so lights use less energy when unoccupied. For warehouse LED lights, these fixtures can transform lighting for your warehouse by increasing safety and visibility while lowering the total cost of ownership.

What is the main source of light in high bay LED lighting, and what is the impact of its performance?

The light source in high bay led lighting fixtures is typically an array of high-power LED chips packaged into modules or COBs that deliver consistent lumen output and color temperature. A quality-led or quality-led high bay will maintain lumen maintenance over time better than traditional bulbs, ensuring lighting helps staff perform tasks reliably. Choosing the right light source impacts glare, uniformity, and how many high bay lights you need for ideal coverage.

Can you give me a lighting guide for determining the use of warehouse LED lights, high bay lights, and so on?

A basic lighting guide includes assessing ceiling height, required lux levels for tasks, layout of racking, and potential for daylight or ambient light. For high bay lights use, determine whether low bay or high bay fixtures are required—low bay for ceilings under ~20 ft, high bay above that. Consider series lights for aisles, lights offer controllable zones, and choose LED lighting solutions designed for damp or dusty conditions if needed. Professional lighting can provide a custom lighting layout to optimize spacing and reduce energy consumption.

What are the benefits of high bay LED when compared to traditional lighting solutions in a warehouse environment?

The benefits of high bay LED compared to traditional lighting include higher efficacy (more lumens per watt), longer life, better color rendering, and lower maintenance frequency. In a large selection of high bay applications, LEDs reduce replacement labor and allow brighter, more uniform illumination that improves safety. Efficient LED warehouse fixtures also enable integration with occupancy sensors and daylight harvesting to further cut energy costs.

How do I select the best LED high bay lights, and what factors determine the quality of LED high bay lights needed?

To choose the best LED high bay lights, consider lumen output, color temperature, CRI, beam angle, thermal management, warranty, and certifications. Factors determining the quality of LED high bay include driver reliability, case design for heat dissipation, and vendor support for a lighting project. For lighting for your warehouse, evaluate sample fixtures in the space or request photometric files to ensure lights are used effectively and meet ideal lighting levels for tasks.

Are there any particular lighting solutions that have UFO light and linear high bay LED options?

Yes, several manufacturers produce lighting solutions intended for commercial lighting and warehouse applications, combining round LED (UFO light) and linear high bay light options. You can use those families of lights to mix fixtures for the racking, open-floor areas, and office or mezzanine spaces. Mixing the types can provide an exceptional light while maximizing cost and energy efficiency for your warehouse or facility.