High bay lighting is of great importance, especially in businesses where huge indoor areas should be lit, since powerful and efficient illumination is a much-needed utility. Two standard choices for high bay lighting are those of Linear and UFO high bay lights, each carrying different designs, performance characteristics, and applications. However, how can you tell which one you would go for, depending on your specific needs? This paper will compare structural, functional, and ideal usage differences between the two lighting solutions, enabling you to become better aware of their features and advantages in making a sounder choice for your lighting needs.

Understanding High Bay Lights

High bay lights belong to a class of industrial lighting fixtures developed explicitly for ceilings at a height of 20 to 40 feet. They are designed to provide intense, diffused lighting over a large area, most commonly areas such as warehouses, factories, and gymnastic styles. High bay lights are recognized for their intense illumination and energy efficiency. They are usually upgraded to LED or HID systems and are engineered to have a high lifespan with lower maintenance. These aim at optimal lighting distribution through their design and placement in ceilings, making them the right choice for illuminating big spaces.

What are High Bay Lights?

High bay lights are a certain type of luminaire that is designed to serve areas with high ceilings, which typically range from 20 to 40 feet. Employed to shine a broad and uniform light on vast areas, the high bay light has a special use in the industrial, commercial, and recreational sectors, such as warehouses, factories, and gymnasiums. It is compatible with LEDs, high-intensity discharge (HID), and fluorescent systems, each having peculiarities offering unique benefits, for instance, low power consumption, high luminosity, and long service life. Located up high in large volumes, high bays have the technology to throw intensive light directed and unabated through shadow and glare against great acreages of perpendicular and horizontal space. Their resistance to weather exposure and low maintenance make them undeniable options for high-stress places.

Types of High Bay Lights

Many types of other lighting sources can cater to specific industrial or commercial demands; however, High Bay Lights are prevalent. Common High Bay Light choices include

LED High Bay Light

They are famous mainly for their high efficiency, lengthy lifetimes, and excellent levels of brightness. These lights are about to save substantial amounts of electricity over traditional lighting technologies like HID or fluorescent, while delivering equal or higher lumen output. In addition, LEDs are known for the process starting up almost instantly, producing a very minimal amount of heat, facilitating further energy-efficient use, and reducing cooling costs for the large-scale industrial sites.

Fluorescent High Bay Light

Fluorescent lights, mostly utilizing T5 or T8 tubes, are usually cheaper and electricity-efficient, so they work well to illuminate simple installations. Though these are able to give better coverage while at a low running cost, perhaps their lesser lifespan and slower starting times as compared to their flashing at a later time, other lento desde luego sus cautchutiencies.

HID High Bay Lights

High-Intensity Discharge (HID) lights, mostly available in metal halide or high-pressure sodium types, are particularly known for their ability to produce extremely bright and focused light. These lights have been in industrial use for many years. However, there are some drawbacks: slow warm-up, high power consumption, and more frequent maintenance needs-probably making them less advantageous than modern LED models.

Induction High Bay Lights

With the potential to last a long time and almost constant light intensity, induction lighting has a downside: its electrode-less nature. The use of this technology is not quite as expensive as that for LEDs, as some find it desirable because of the reliability and energy efficiency coupled with the quality of illumination in applications that require minimal or no maintenance 24/7.

The selection of a high-bay light type depends on things like the intended purpose, required brightness, energy efficiency goals, and maintenance requirements. Due to the outstanding performance, efficacy, and durability expected of LEDs, the preference towards LED solutions is increasing.

Applications of High Bay Lighting

High bay lighting is meant for a range of environments, including those with large vertical spaces requiring viable lighting. The most common applications are warehouses, big enough to provide enough vertical space for lifting heavy materials. Factories or warehouses are installed with enough luminaire to provide a glare disturbance in front of the workers’ eyes. Besides industrial buildings, big-box stores plus supermarkets are among the most common examples of retail space that benefit from high bay lighting technology. Besides the right level of visibility required in these rather large shopping/media environments, high-quality light glorifies the productivity of this technology. Also, high bay lighting may be used in contemporary sports arenas or even school gymnasiums, where it possesses the capacity to illuminate grand open areas that then allow optimal performance and viewing conditions. Other applications could include transportation terminals, such as airports or railway stations, as well as exhibition halls, where high ceilings necessitate the utility-force technologists to maintain both form and aesthetics by lighting in large spaces. Well-suited for the sort of super-structure lighting, high bay lighting could make for energy-efficient and long-lasting solutions that are feasible for modern infrastructure.

Linear High Bay Lights

The primary intention of linear high bay lights is for long and narrow spaces with high ceilings, such as warehouses, manufacturing facilities, and large retail stores. These lights ensure uniform lighting in large areas, thus enabling better general visibility and reduced shadows. They use LED technology, making them energy-efficient, low-maintenance, and offering high longevity; hence, this lighting solution presents as a good deal for industrial and commercial applications. Linear high bay lights are designed for optimum brightness over racking or aisle configurations that best maximize the available lighting.

Features of Linear High Bay Lights

One of the most significant reasons for the adoption of such linear high bay lights is their power efficiency. LED technology promises fewer long-term effects on the die casts, resulting in very economical lighting over the years by optimizing the number of light lumens (lm) per watt used.

Resistance and Shelf Life: Sturdy in their body build and great in modern LED materials, they last beyond 50,000 hours’ service within industrial environments, thus leading towards saving on costly maintenance and replacement sprees.

High-Quality Lighting: Class outnumbers clutter. Linear high bay lights that use highly luminous efficacy abilities through non-uniform and flicker-free lighting. This will always make it the showstopper at any workplace for safer and productive jobs.

Good design versatility.

The linear design of these luminaires is best for rack- or aisle-layout environments, like in warehouses and storage facilities, for very focused illumination in the very spots where light is required, with no dark spots or shadowed areas.

Dimming and Intelligent Features

A few features integrate dimming and intelligent controls for compliance, where users can set their brightness level or customize their lights to dim levels and switch on and off at specific times. This kind of operation makes the lights easy to use and promises a significant amount of energy conservation.

Installation Comfort

Tailored for easy installation, linear high bay lights are typically lightweight enough for various mounting options-restraint chains, brackets, or pendants. This flexibility simplifies installation at various facility types.

Thus, linear high bay lights combine cutting-edge efficiency with practicality to form the perfect lighting option to meet the demands of modern commercial and industrial applications.

Advantages of Linear High Bays

Energy Conservation

LED technology is utilized by high bay lights. These linear high bay lights show a massive improvement in energy efficiency, compared to traditional types of lighting such as metal halide or fluorescent fixtures, and these fixtures give a high long-term saving factor on energy.

Improved Illumination Performance

These linear high bays are generalized by their high lumen output and superior uniformity, which fascinates hard spaces.

They are engineered to ensure very minimal glare, much crackle-free distribution of light to fill the entire space, and luminous visibility that makes them the most suited for places like warehouses, gymnasiums, and industrial settings.

Long-Life Operational Efficiency

Built to be strong and give a lifespan of up to 50,000 or even more hours, which will cut away any extra cost involved in the process of maintaining and replacing any heavy-duty working tire. A strong construct with materials that are heat-resistant, corrosion-resistant, and resistant to impact provides further assurance of reliability under rigorous conditions.

An Option for Customizing and Flexibility

Linear High Bays are available in an array of wattages, beam angles, and mounting options, thus making them perfectly suited for varying applications. Dimming capability and Smart Control compatibility further add to the factor of adjusting light levels according to requirements, optimizing energy conservation.

Eco-Friendly

These lights contain no hazardous materials like mercury and give lower CO2 emissions compared to the usual lighting solutions. They can be recycled, aligning with sustainable goals.

Through cost-effectiveness, high efficiency, and eco-friendliness, the linear high bays are the ideal choice for lighting up humongous areas without fail.

Best Uses for Linear LED High Bay Lights

Retail and Commercial Spaces

Linear LED bay lights with high lumen output are suitable for large stores like supermarkets or warehouses, creating a bright atmosphere that allows products to be adequately exhibited from considerable distances while also maintaining efficient energy usage. As a result, the maintenance and operation costs would end up lower.

Hangars and Transport Hubs

Lighting in high lumen output is indispensable in using the characteristic reliability to cogent illumination settings for whatever dependable safety lighting is needed, which refers to detailed work like airplane maintenance in warehouses and huge train sheds.

Wherever high-efficiency, large-area lighting is called for, the unique ability and high quality of linear LED high bay units stand as the only feasible option.

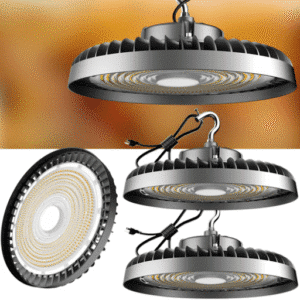

UFO High Bay Lights

Round LED high bay lights, also termed UFO high bays, have been designed for high-ceiling applications, common in warehouses, manufacturing plants, and large-scale retail buildings. The name “high bay” has been aptly derived from the elevated height at which it is installed. Their high-intensity, uniform illumination is particularly useful for setups demanding precise viewing and improved safety. Durable and energy-efficient, they are easy to install for quick and easy maintenance with a leading-edge design to resist harsh conditions. It is small and round in shape, thus ensuring a uniform light beam and lighting all profiles in a better way, offering a more reliable lighting option without incurring much cost in commercial and industrial applications.

Characteristics of UFO High Bay Lights

Higher Wattage

UFO LED high-bay lights consume energy and produce light mostly in the form of lumens. Such lights require a lighter output of lumens per watt to be comfortably said to work properly; therefore, in large, ample spaces like warehouses, gyms, or manufacturing facilities, these lights prove very useful due to their very high CRI. Plus, of course, a higher CCT as a washing light solution. Light fixtures with few lumen outputs can consume a little more energy, and, on the contrary, energy with fewer watts produces fewer lumens. Hence, the money-saving factor is about to change, while service life also becomes less enduring over time.

Energy Efficiency

These UFO LED high-bay lights can work efficiently when juxtaposed with lamps from before the year 2000. These LEDs reduce the loss of watts, making them eco-friendly.

Durability and Longevity

Constructed with robust materials like aluminum housing and advanced thermal management systems, these lights boast longer lifespans, often exceeding 50,000 operational hours, and are resistant to dust, water, and impact, ensuring reliable performance in demanding environments.

Compact and Lightweight Design

The circular and small dimensions facilitate easy installation and service. The lights also feature a lightweight design that supports easy mounting on ceilings of varied heights without any extra support.

Customization Opportunities

Several UFO high bay lights have additional options, allowing you to fit the luminaire with adaptive lighting for motion sensors and dimmable abilities. The multitude of beam settings helps to further cater the beam intensity to client requirements. The various improvements in LED elements have ensured that the color temperature can be instantly changed in fields and tasks.

Wide Application

These lights are suitable for every industrial and commercial application – the lights can be used in warehouses, retail outlets, arenas, manufacturing plants, etc., illuminating uniformly in varied settings.

With specialized advanced performance, hardy designs, and tailored features, UFO high bays are both practical and inventive solutions for present-day overhead lighting requirements.

Benefits of UFO High Bays

For energy-saving mechanisms, UFO high bay lights are equipped with the best LED technology. As a result, they suck much less than metal halide or fluorescent fixtures, resulting in much lower electricity usage and the untouched use of the extra fine carbon prints.

It’s uncommonly light and functional

Few luminous sockets are very bright in order to provide the same level of lumens and excellent CRI (color rendering) for large spaces, and hence provide the best possible visibility. These units were created to efficiently restrict glare and hold a great amount of uniformity in the beam distribution over very large areas.

Long Life and Durability

Incredibly long-lasting UFOs are manufactured from rugged materials with designs to withstand heat. Lifetime expectancy is expected to be around 50,000 operational hours, and thanks to their hardy build, the maintenance periodicity and timeframe for replacement are compressed beyond a point larger than the other entered.

Applications and Versatility.

“Such lights work well in many setups: factories, distribution centers, sports facilities, retail outlets, or manufacturers. Their dynamic adaptability makes them useful for both indoor and semi-outdoor applications.

Green Design

There is no mercury in the present light; it is recyclable. It is contributing to green practices. The environmentally unequivocal efficiency bulbs are also an excellent choice for green building certifications; energy codes offer the green technology that defines these lights ‘ identity.

In the face of scalably, sustainable performance with respect to energy efficiency, minimal maintenance, and flexible adaptability, UFO high bays stand as the perfect solution to the modern energy-efficient requirement.”

Ideal Applications for UFO LED High Bay Lights

UFO LED high bay lights are specifically designed for lighting large spaces with tall ceilings, typically varying from 15 to 50 feet. Their rugged design and high efficiency would suit various environments for their best kind of illumination and safety. The principal applications are as follows:

Warehouses and Distribution Centers

The UFO LED high bays work best in providing illumination within warehouses and distribution centers owing to high lumen output and uniform light distribution. Studies have shown that productivity increases by almost eight percent when a facility maintains a well-lit environment, and that the accident rate drops due to improved visibility.

Manufacturing Facilities

Warehouses and manufactories receive dividends from UFO LED high bay lights in terms of resistance to harsh environments and durability. These lights are very suitable for operating within such premises, even if temperatures register high, dust settles, and vibrations are felt. Thus, minimized maintenance requirements are a sure means to lower running costs when considering luminaires that last 50,000 operating hours or more.

Court Arenas and Recreational Facilities

Indoor sports complexes are mostly lit with high bays, as this luminance is uniform and glare-free, thus promoting the utmost comfort for athletes and spectators. Advanced systems identified in some models help dim the light when needed for events or training sessions by virtue of energy conservation efforts.

Retail Spaces with High Ceilings

Large retail spaces, like warehouses or wholesale clubs, use UFO high bay lights to make the place brighter and more attractive for customers. Bright lighting in big retail spaces is known to carry with it a number of benefits, like increasing customers’ roaming time and hence boosting their shopping experience.

Cold Storage and Food Processing Industries

UFO LED high bay lights are subject to cold storage and food processing. Staying operable in sub-zero temperatures ensures compliance with the standards of lighting as well as energy-efficient practices.

Airports and Transportation Hubs

Tools to brighten high altitude areas such as terminals, hangars, and transportation hubs with UFO LED high bays- economically able and efficient lighting.

UFO High Bay LEDs deliver an impressive boost to traditional lighting alternatives in retail and manufacturing environments, offering unmatched lighting performance, energy saving, and flexibility in application.

Comparing Linear and UFO High Bay Lights

Design and Shape

Heave DEC-101-8040 lights are rectangular in shape and evenly distribute light around the area; this feature is ideal for use in an open, narrow place. UFO DEC-101-8040s lights find application in an even light concentration and uniform, omnidirectional distribution of light in wider spaces with high ceilings.

Application

Linear high bay lights are suitable for areas such as warehouses with racking or shelving that can form rows. Some good examples of the utilization of UFO high bay lights are gymnasiums and industrial applications in large open spaces.

Installation

Sometimes, linear lights may require more complicated installation processes since they are bulkier and larger, whereas UFO high bay lights are compact and are relatively easy to mount, usually using a single suspension point.

Efficiency

Both types are highly energy-efficient; however, UFOs are the best option when taller, wider coverage is needed with minimum energy consumption because of a quantum amount of lumen output, while linear high bays focus more on uniformity over large, narrow areas.

One must therefore study the specific requirements of the space and then choose between UFO high bay and linear high bay lighting, as it can bring about a performance and energy efficiency balance.

Energy Efficiency: UFO vs Linear High Bay

Consequently, lunar high bay lights rank low on the energy efficiency scale either way. Whereas UFO high bays come with an exceptionally high lumen per watt performance, just right for high-ceilinged spaces demanding very intense and focused illumination. In addition, its round design makes it literally immune to light scattering, allowing it to send the light straight down the ground, where it must be used 100 percent efficiently.

On the contrary, linear high bay lights can be dwarfed by their UFO counterparts as far as lumen per watt zenith is concerned. But it can boast of an even canopy of light used for rectifying elongation and width `adjacency´. As such, warehouses or stores really beg for such pendant lights or UFOs. Urban high bay lighting fixtures are much favored owing to their performance; LEDs for saving energy are used for either of the options.

The choice between one fixture and the other is down to the lighting requirements of a particular space. An optimal choice for targeted, high-lumen applications involving hardly any loss in energy, UFO-based high-bays serve as an ideal example. By contrast, linear high bays give just the perfect blend of coverage and high efficiency, creating a broader, more evenly distributed light distribution.

Lighting Performance: UFO High Bay vs Linear High Bay

Adjoining the lighting scenario, UFO high bay and linear high bay luminaires empower unique advantages for the postulated applications. UFO high bays are geared for really high-lumen output applications that require highly concentrated lighting output, such as high-ceiling warehouses or places where highly precise lighting is required. Toward this end, the lights’ circular form is specifically engineered to deliver downward light and produce little spillover, keeping it tied to the area one aims to illuminate with the highest precision.

On the other hand, linear high bay fixtures turn in subtler, more consistent light points compared to the concentric light pool and find spaces with high square foot area illumination very suitable: stores, sports halls, and factories. They are meant to give uniformity of light board pathways that are shadow-free for maximum visibility.

The strength of fixtures on each side of the spectrum lies in the use of high-power LEDs, which allow them longer lifetimes, lower heat output, and ultimately result in energy savings. The choice of picking one over the other with respect to UFO High Bay Fixtures depends on the operational requirements in a space, typically-while Linear high bay Fixtures are best for wider potential applications.

Cost Considerations: High Bay vs Linear High Bay

Certainly, UFO high bays are particularly cost-effective due to their designs, quick installation, and generally even more fantastic efficiency than linear high bays. Their uniqueness lies in the fact that their size being so small allows for quick movement during installation, hence lower labor costs. It is particularly good for facilities with high ceilings and a need for targeted lighting system performance. On the contrary, linear high bays, even though initially generally costlier, can scatter light more and daylight better for broader, more open areas such as warehouses or gymnasiums. The higher acquisition cost is generally softened by the larger area where such light fixtures will get to reduce the expense of fixtures in large areas, yet achieve better-quality lighting as compared to UFO high bays. Both UFO high bays and linear high bays are excellent options that value energy-efficient LED technology, enabling them on an even playing field to minimize long-term operational costs resulting from diminished energy consumption and very long operation life. The choice, ultimately, is perpetually guided not only by solutions but also by lighting objectives, as both fixtures present highly competitive cost benefits in diverse circumstances.

Choosing the Right High Bay Light for Your Warehouse

High Bay Light Looking For Your Warehouse? Here Are Some Key Points:

Ceiling height: High-bay lights are the best options for ceilings ranging between 15 and 40 feet. Kindly observe the ceiling height of your house to ensure accurate spread of light.

Lighting Requirements: Lumens must verify the required brightness to ensure safety and productivity.

Efficiency: LED fixtures are more energy efficient, but this is less energy-saving as compared to traditional fixtures.

Material temperature: The color temperatures may be selected depending on your work environment. Neutral White (4000K-5000K) is standard for use on shop floors as it combines clarity and comfort.

3. Durability: Consider fixtures that have strong construction and IP ratings when your warehouse environment is dusty, damp, or otherwise challenging.

After evaluating those elements, we can choose the high bay light that best fulfills our needs in terms of performance and cost-efficiency.

Assessing Your Warehouse Lighting Needs

When assessing the warehouse lighting needs, one should ensure that key considerations are as follows: properly illuminated areas, energy efficiency, and productivity.

Layout and Functional Areas

Examine your warehouse layout to identify which spots are assigned for storage, loading dock, office, or workstation. Higher illuminance levels, typically around 300-500 lux, might be required in areas involving usually more precise tasks, and in areas such as general storage, lesser values can be used (typically about a hundred to two hundred lux). These can be partitioned by various task-specific lighting requirements if these solutions were to be laid out.

How Much Light Should Be There (Lumen Output)

How many lumens will it be? This depends on these things:

The square footage of your warehouse and the necessary levels of lux. High ceilings will necessitate high bay fixtures to give sufficient lumen output and maintain uniformity of light throughout the area – lumens shown to be stronger than 10 ft-candles. However, standards (IES, e.g) in the lighting industry serve to provide the right recommendations.

Assessment of Energy Efficiency and Cost]

By taking these considerations into account, as well as the environment, such as temperature, dust, and humidity, you can make sure that a warehouse lighting system supporting operational needs and appropriate harmonious manner is placed there. Working safety and efficient operations can be achieved by providing precise solutions according to these requirements.

Factors to Consider in Your Lighting Solution

I consider several important aspects of any lighting solution so that it is efficient and effective. Firstly, I evaluate the available lumen output and energy efficiency, where my emphasis will be on high lumens-per-watt fixtures, which are ENERGY STAR-certified; they are worth considering because they help to reduce energy costs. Thereupon, I try to deal with the light intensity of space, which is concerned with qualifications such as uniform light distribution and brightness requirements for better visibility and safety issues in the space. The environmental conditions, including temperature, humidity, and dust levels, are also an important consideration; they directly influence the longevity and performance of lighting fixtures. It is with this intention of addressing such vital factors that we may be able to come up with a tailor-made solution effectively meeting operational requirements.

Conclusion: Making the Right Choice

Selecting the best lighting solution is contingent on careful considerations of aspects such as energy efficiency, aesthetics, and user friendliness. Compact LED systems may as well emerge as a significant player in the never-ending energy-efficient lighting struggle against inefficiency. That will result in energy savings, which will significantly cut output costs. In the end, smart design calls for something more considerate of users. Analysis of specifics of a room’s working requirements with respect to lighting conditions, their brightness, evenness, and severity of operation, will go hand in hand in ensuring safety through the efficiency of the chosen light fixture. Following the specified standards through awareness and reference ensures solid judgment for the client, one that speaks technically to the here and now and into the future.

Reference Sources

Frequently Asked Questions (FAQs)

How is UFO LED high bay lighting different from linear high bay lighting in industrial applications?

In comparison of a UFO light and a linear high bay light, there are differences in shape, beam spread, and application. UFO high bays are round lights that concentrate light into a smaller area with tighter beam distribution, with lofty ceiling heights and allotted task areas being their key locations, while LED linear high-bay light diffuses illumination evenly across open spaces and aisles with the highest ceiling height. While many LED ufos offer fewer alternatives, they put out high lumens from a relatively low wattage, providing high-energy efficiency and high brightness; on the contrary, LED linear high bays concentrate light more to evenly spread, also equally provide maximum coverage to long, narrow spaces in industrial lighting.

The contrast in lighting performance is as follows: UFO vs linear vs linear high bay LEDs?

In LED bulbs, the LED lamp employs reliability and generates light with very little heat energy. The method creates light focused on specific areas rather than being evenly distributed throughout a large expanse. Unlike an incandescent light bulb’s brightness, a LED light’s brightness is extremely linear, ascending softly as the LED current becomes stronger. Being mounted high above the ground, a UFO high bay of 150 W will not produce intense illumination but rather flooded rays, giving us a perfect example of laser illumination.

How would the efficiency of UFO and linear LED high bay compare with that of old fluorescent tube lights?

Switching the light fixture from an old fluorescent tube to a UFO and linear LED high fixture can offer many advantages: high-energy efficiency, low maintenance, immediate full brightness, and improved color rendering. The LED linear high bay often eliminates flicker, ballasting needs by eliminating the ballast and hence delivers more stable operation. Compact designed ceiling-focused high bay lights offer excellent illumination in exceedingly high applications. With such advancements, facility managers can now make informed decisions regarding retrofits and long-term operating costs.

When are UFO high bays and linear lights better for large open areas with high ceilings?

Good designs are suitable for very high open spaces, tall halls, malls, and open industrial hangars and Disperse, high illumination is required. Most industrial lighting fixtures have bright lumen output, and Industrial bay lamps provide optimized light output. Also, it is mostly what defines the choice between Linear LEDs and UFOs.

How do UFO and linear high bay lights influence visual comfort or glare?

UFOs are the source of focused light, causing some glare without directed or admitted diffusion. This is especially the case with respect to work for visual comfort. The linear high bay disperses light, so it reduces contrast and shadows and improves comfort for workers doing precision work. Proper choice of optics, diffuser, or lens helps to obliterate the glare; luminaries typically have an architectural design that facilitates even, comfortable, glare-free light formation.

Is it advisable to mix UFO lights and linear high bay lights in the same facility?

Yes, UFO lights and linear high bay lights can be combined wherever the facility has different zones; use UFO fixtures for areas with extremely high or high intensity, such as loading docks and tall storage racks, while using linear high bay LED lights for walkways, production lines, and workstations needing an equal amount of light from all directions. In this integration, the benefits of both immersive approaches synergize so high bay lights address pinpoint light requirements on-demand, and remaining zones receive uniform light distribution due to linear high bay lighting.