When it comes to industrial and commercial lighting, ensuring that the right fixture is chosen is crucial for functionality and efficiency. Choices primarily lie between high bay and low bay. These are designed for specific applications and environments. What distinguishes the two other than specifications, and which one is suitable for use? Here, we compare high bay and low bay lights and explore their relative design applications and optimal use. Summarized herein is a good investment for decision-making, especially when you are lighting a warehouse or a small retail store: these distinctions may either cloak the decision with much-needed enlightenment or bewildering confusion in matters concerning visibility, safety, and energy conservation. Go ahead and give an insight into the working of these design mechanisms and what sets them apart.

Understanding Low Bay Lights

A low bay light design is created for environments with a varied ceiling height. Most are between 12 and 20 feet up to the ceiling. The distributed wide light across the spaces occupied by low bay lights makes this product perfect to use in places like retail outlets, workshops, and small warehouses, just to name a few. The specific design procedures to maintain quality minimize glare on the lower ceiling and increase visibility for the subtler lighting effects required by low ceilings. This light product is available with diffusers or reflectors to help with the distribution of light and eliminate shadows for the complete convenience of occupants.

Definition and Purpose of Low Bay Lights

Low-bay lighting specifically refers to lighting supported by fixtures having a ceiling height ranging from approximately 12 to 20 feet. This type of lighting serves to provide a consistent, efficient contrast to the areas having lower ceiling heights, avoiding any dark spots that can occur. Many a time, this lighting provides good reflection due to the diffusing or reflecting elements built into the fixture while reducing glare and casting harsh shadows, leading to a more visually comfortable environment. Low bay lighting is frequently employed in settings like retail stores, garages, manufacturing buildings, and smaller warehouses. These lights are designed for energy efficiency and optimal performance, feature good lumen maintenance, and have a long natural life. Enhancing this is their low energy consumption, which ultimately results in budget-saving; hence, various technologies may be utilized, including the one based on the LED concept.

Applications of Low Bay Light Fixtures

Designed specifically for areas with ceiling heights ranging from 12 to 20 feet, the low bay fixtures provide consistent lighting and increased energy efficiency. They are typically employed in retail settings, where having the means to illuminate product displays and offer customers attractive overall lighting makes or breaks the result. To serve this objective, they are also applied significantly in auto workshops and garages, diagnostic lighting while aiding in detailed tasks. Distributed differently, low bay lights also serve as a key component in small-to-medium warehouses for ensuring complete illumination spread, by minimizing shadowing in storage areas and workstations. Lastly, going into areas in educational institutions like gymnasiums and cafeterias, they have been incorporated in very high-traffic areas using extremely durable and efficient lighting systems.

Benefits of Using Low Bay LED Lights

Numerous advantages accompany the low bay LED lights intended to meet functional demands across varied settings. A few of those include:

- Energy Efficiency: The low bay LED lighting was meant to operate on much less energy than is necessary for traditional lighting sources like the fluorescents or halogens. This stands for low electricity bills and, thus, the environment and economy of some kind or even the other for all organizations and institutions.

- Longevity: The low bay LEDs that have been constructed with an average life of more than 50,000 hours do not have to deal with the high turnover of replacements anymore, thus actually saving both labor and associated costs of maintenance. They continue to offer effective luminance under heavy lighting.

- High Light Quality: Low bay LED light gives an even and bright light without any extra glare, making it easy to see around garages, warehouses, and educational centers. Many of these LED lights also have a top CRI rating, in perfect predominance to the tasks at hand.

- Heat Management: Unlike many traditional lights, which lose energy in the form of heat, LED bulbs rarely produce heat, so they allow cooling costs to be minimal with minimal risk to the operating environment, and are peculiar to tightly-controlled or industrial installations.

- Sustainability: LEDs (low bay) of this century are entirely free of hazardous materials and cost far less in terms of their carbon footprint in comparison to traditional lighting systems, so these can be found in various spaces where our mission involves a paramount aim to meet environmental goals. Their long life enables you to save landfill waste pertaining to increasingly frequent changes of gas.

To accomplish this in low-bay LED lighting systems, facilities attain higher results in terms of illuminating, saving costs, and aligning with contemporary energy-efficiency standards.

Exploring High Bay Lights

Particularly designed for higher ceilings, high-bay lightings are applied to areas generally 20 to 40 feet or more in height. They provide strong illumination of wide spaces in hospitals, in warehouses, and in plane hangars. By design, as light points straight away with virtually no loss, uniform lighting is maintained even from great heights. This high-bay light is, indeed, very worthwhile with its energy efficiency, long life, and low maintenance requirements compared to conventional systems and is thereby advantageous to numerous sprawling operations.

Definition and Purpose of High Bay Lights

High bay lights are specialized lighting fixtures that are designed to light spaces having long-reaching ceilings. They are typically found in spaces whose ceilings are 20-40 feet or more in height. The lighting fixtures produce really powerful and uniform illumination and can help achieve optimal visibility in locations with high mounting elevations. Commonly operated in industrial settings, manufacturing plants, warehouses, gymnasiums, and other large facilities, the high bay lights ensure safety and increase productivity by reducing shadows and glare.

Above and beyond ordinary luminosity, high bays are the adopted type; they are built for strength and maximum light diffusion under the most demanding circumstances. High bays frequently center around the use of advanced optics and energy-efficient technologies, including LEDs, which can significantly reduce power consumption as well as maintenance costs while providing a consistent and high-quality light. Hence, high bays are versatile and dependable tools for anybody who needs powerful and effective lighting solutions.

Applications of High Bay Light Fixtures

High bay lighting fixtures are designed to provide plenty of lighting in places with high ceilings, usually from 20 to 40 feet, and sometimes even more. These types of lighting systems are suitable for various industries and settings, such as:

- Warehousing and Storage Facilities – High bays serve as the best illumination for massively open spaces, incorporating towering rack systems to ensure the lighting is properly bright for workers to operate safely and efficiently.

- Manufacturing Facilities – High bays provide the required level of illumination necessary for precision work; they limit breaking shadows and increase the productivity level in factories.

- Sports Arenas and Gymnasiums – They must also emit sufficient and uniform light that has the luminance required to ensure the highest possible level of visibility over extended distances across an outdoor field or sports arena.

- Retail Stores & Supermarkets – With excellent fall of light, high bay fixtures become best suited to provide a well-lit and warm atmosphere to the customers in such demanding areas as stores with high ceilings.

- Airplane hangars – For maintenance and inspection tasks, these spaces need strong and reliable light, making high bays a preferred choice.

- Convention centers and exhibition halls – High bays illuminate large venues and aid visibility while merging with aesthetics.

Their adaptability across various spaces and employment of cutting-edge LED technology facilitates solving the challenge of efficiently illuminating an extensive area while cutting back on energy costs.

Advantages of LED High Bay Lighting

- Energy Efficiency – LED high bay lighting systems take away upon large portion of power as compared to traditional lighting systems, including metal halide or fluorescent fixtures. Reduced electricity consumption translates into significant cost savings over time.

- Long-Life Ensurance – LEDs are made to stay operational for longer periods, hence offering longer life spans compared to their usual counterparts. LED high bay lights last an average of 50,000 hours minimum, thereby requiring very little maintenance and fewer replacement requirements.

- Great Light Quality – Comprehending the high Color Rendering Index (CRI)—LED high bay lights bring out true color representation with a strong sense of uniform illumination. This will be a good reason for superb illumination for situations requiring precision visibility, such as those occurring in the warehouses or on the factory floors.

- Less Heat Generation – LED lights generate a notably lower heat output than do conventional lights, thus improving safety and saving air conditioning costs in temperature-sensitive surroundings.

- Environmental Sustainability – Because they lack substances like mercury, LEDs are highly efficient and easy to recycle, thereby adding further points in their favor. Another aspect of energy efficiency reduces carbon footprints.

- Customize and Adapt – LED advancement allowed for fine-tuning settings to produce cool and daylight ambiance. LED technology sees the highest possible efficiency when compared to conventional lamps. LED orientation facilitates lightweight luminaires with negligible lumen erosion.

- Instant Glow and Zero Flickering – Flickering and warm-up time are extinct to LEDs. LED high bay lights go into full intensity the moment they are switched on. Many such improvements increase performance and work place comfort, and reduce strain.

High bay LED lighting systems are ideal for vast and specialized applications, combining cutting-edge performance, cost-effectiveness, and environmentally friendly operation.

Comparing High Bay and Low Bay Lighting

High bay lighting is designed for high ceilings, commonly over 20 feet; low bay lighting is for ceilings under 20 feet. Thus, high bay lights are mounted inclinedly or vertically in large spaces, concentrating illumination over distances, as would become necessary in warehouses, large garage spaces, or industrial and commercial settings. Low bay lights are smaller and provide brighter light; on the other hand, if a light should be directed into a single beam for more intensity, a high bay light should be used.

Another difference could be derived from design; high bay lights seem to incorporate reflectors or lenses, preventing the loss of light. Low bay lights are close to the area to be illuminated, so design features might not be needed. Deciding between high and low involves floor elevation, plus the light requirements of the space.

Main Differences Between High Bay and Low Bay Lights

The primary difference between high- and low-bay lighting is their application based on ceiling height. High-bay lights are designed for ceilings in a range of 20-40 feet, predominantly seen in warehouses, industrial facilities, and production plants. They can project light effectively over great distances from far heights, using reflectors to focus the light across specific areas or lenses to offer a broader, softer coverage. Low-bay lights, on the other hand, are placed at considerably lower heights, typically at less than 20 feet, in retail areas, garages, or workshops where the lighting needs can be less intense and more evenly distributed.

Another critical difference is their construction. High bay fixtures often incorporate slightly advanced optics where bright light with higher lumen output should reach the work surface, ensuring that enough light reaches the working surface even at a vast distance. Again, low bay lights, on the other hand, generally have what is traditionally considered a low amount of lumen output and are characterized by a smaller distance to the ground surface, so they do not necessarily need very complex reflectors. The lighting environment must be assessed; ceiling height, space size, and the requested light distribution should gloriously rule the selection of the proper fixture. This will result in a lighting system that can effectively satisfy a unique ambient need with optimal energy efficiency and performance.

High Bay vs Low Bay: Which One to Choose?

When a decision is to be made for the lighting of high or low bays, the ceiling height, the functional conditions, and the purpose of lighting must be considered. High bay lighting generally tends to be good for facilities with ceiling heights extending above 20 feet-like warehouses, manufacturing plants, and several places of the same sort. Rarely do they ever illuminate over 20 feet, as the fixture is aimed to make intense, beautiful light focused across a wide area from the necessary, often substantial elevation. Contrarily, low bay lighting does well with spaces while the ceiling is not quite as large a measure in comparison to high bay places, like retail buildings, garages, and workshops. These fixtures pump out less intense light at this height-although far-reaching, all the smaller, more enclosed spaces are formed.

Considerations for optimal lighting involve the nature of the specific environmental needs. In the instance of high bay lighting, advanced reflectors are coupled with an extensive range of LED optics to maximize and distribute the light, which enables efficiency and precision for larger application-sized spaces. Fixtures in the low bay sector, on the other hand, concentrate more on the distribution of light at close range, simpler designs, and lower lumen output. Understanding the operating efficiencies, energy efficiencies, and area applications that set the performance of these two types of fixtures apart and drive the selection helps stakeholders achieve their operational goals while minimizing energy consumption and maintenance costs.

Factors to Consider When Choosing Between High Bay and Low Bay

Efficiency of Energy

Besides products and services, energy usage and conservation were overlooked in the matter of construction companies. Energy efficiency with potential savings of 8-10 percent is a lot less than the discrepancy that an energy-efficient building is capable of.

Construction companies can help by purchasing renewable energy from their licensees, whether it be a provider in their home state or a green certification program. Integral operators need energy delivery in a more meaningful way so that their products can still be considered partially green, with much advanced material to be installed in green buildings.

Sensors can embed all information, determine capacity, and respond to the exact extent of need. It considers creating new opportunities to reify machine translation to enact deployment, automating the most energy-efficient full life cycle, and completing the LEED green building.

Energy efficiency and fixture maintenance frequency are important factors. High bay LEDs are very energy efficient for large spaces, providing long-term savings in operational costs. Low bay LEDs generally consume less energy to begin with and require less installation and maintenance as they have generally simpler designs and are placed lower. Therefore, both options should be evaluated for the best lifecycle costing.

Special Application Requirements

When choosing between high bay and low bay lights, consider the surroundings and operational requirements. High bay lights would be best for spaces with tall ceilings for industrial operations such as warehouses or factories, or for places where high visual clarity is required. For retail stores, parking garages, and workshops with low ceilings that require even, diffused light, low bay lights are the best.

These factors will give an understanding of how this lighting solution could work after it has been tailored to the specific spatial and energy needs, keeping maximum functionality and efficiency in consideration.

Choosing the Right Bay Lighting Fixture

A good high-bay light for warehouse use should be much more than just that; amongst other things, it would emphasize long lamp life, wide light coverage of the products, while not neglecting light quality. A lumen package of 15,000–30,000 lumens, a color-temperature option of 5000 or 4000K, a life span of 100,000 hours, a power capacity of 150 to 200 watts, and no fragile glass—one with all these features, perhaps being made mandatory for warranty, would duly serve the purpose.

Despite the brilliance of the lighting intended for the warehouse being quite remarkable, it is quite the opposite regarding maintenance; most of the low-bay lights do require very little maintenance. Many of these short forms will incorporate the ballast into the lamp itself for those low bays, a fact that adds to their being low-cost and compact in comparison to other light fixtures.

Measures can reduce reflected glare from the lens and create a wide floodlight effect over an area—the exact type required for such areas as parking spaces, retail shelves, kitchens, and dining rooms.

Factors to Consider for High Bay vs Low Bay

When considering high bay versus low bay lighting, it is of utmost importance to consider a number of key factors in analyzing the most suitable solution for any given space.

Ceiling Height

With regard to ceiling height, high bay fixtures are designed for underceiling heights of 20 feet and higher, in order to emit light that will concentrate effectively for faster descending. For rooms with ceiling heights under 20 feet, the spatial lighting area is unnecessarily outspread.

Light Distribution and Beam Angle

Typically, high bay LED fixtures are built with quite narrow beam angles (60-90 degrees) in order to direct light to a specified area for high applications ceilings. Low bay fixtures have a very wide beam angle of 120 degrees or more, usable for spreading light uniformly across shorter distances.

Use Cases and Illumination Requirements

Ideal for use in gymnasiums, industrial facilities, and to illuminate large warehouses that require high illumination, high bay lights are more cost-effective than low bay lights. For workshops, retail stores, or garages, low bay lights can be much safer because they give a much softer and uniformly distributed light while reducing glare.

Performance and Maintenance

Their amazing energy efficiency and minimal heat emission easily lend LED technology as the standard case study across both technologies. Maintenance costs are also lower as a result. It is, in fact, no exaggeration to state that LEDs give longer working hours than conventional metal halide or fluorescent lights.

Price and Features

Both categories would cost you very little in the form of operational costs in the long run. The initial price of high bays as compared with low bays can, however, be looked at. You should also be able to tell whether simple installation and mounting means, such as hooks, chains, or pendants, would work, given the constraints of the working environment.

To place your light effects within these guidelines, realigning with both function and economy, requires a good structure of detailed questions to ask about areas within an open-ended format.

Best Lighting Fixtures for Different Environments

Choice of lighting fixtures depends upon specific applications, facility needs, and performance targets. Following is a summary of the available wisdom:

Warehouses and Industrial Indoors

From above, high bay lights are the excel pick if the ceiling heights exceed 20 feet in any case. Commercial warehousing, manufacturing floor, and industrial construction spaces are perfect candidates for them. LED high bays are the best among all: they provide energy efficiency, high lumen output, and demand less maintenance. For outdoors, outdoor bulkheads are good options as they have higher sunlight tolerance and pass regulations without causing any discomfort.

Retail Spaces and Commercial Settings

Low bay lighting forms a common choice for commercial settings, taking into consideration that ceiling heights are usually lower than 20 feet. These offer evenly distributed illumination over aisles and product displays. One incredible feature of these lights is their customizable color temperature LEDs that allow you to set the ambiance of your space according to the comforting presence desired by your customers, boosting your sales, of course. The dimming feature keeps the possibility of adjusting lighting conditions in accordance with a given time or function.

Offices and Educational Facilities

When used in an office, school, hospital, or any such area, troffer fixtures or panel lights are an optimal choice. This offers more of a kind of shadowed or diffused light, allowing better working conditions, reducing eye strain, and increasing work/productivity. Possibility has to be made and looked out for a fixture with the color temperature within a range of 4000K and 5000K. Nowadays, environment-friendly blocking non-energy-consumption LED solutions are thought to be the best.

Healthcare and Clinical Environments

The cleanroom-rated LED lights are vital for clinical and health-focused environments. Please ensure that the fixtures you select come equipped with a high Color Rendering Index (CRI) for accurate diagnoses and patient care. Sealed designs do not allow contamination, and the innocuous LED minimizes flickering, creating a calming atmosphere. This way, the LED lights provide an engineer with a perfect way to operate lighting in custom-designed environments with ceilings of different heights, different brightness requirements, and different energy-efficiency needs.

Warehouse Lighting Solutions: High Bay or Low Bay?

Whenever the situation arises on whether high bay or low bay lighting should be installed in a workplace, a crucial determinant remains the elevation of the ceiling and the application in the warehouse. A high bay light is primarily designed to be installed on ceilings higher than 20 feet with bright light well-distributed within a particular space. This style of lighting often serves as a reflector design or lens technology used on the lamp to direct light downwards very efficiently. Suppose the demand is for a ceiling below 20 feet. In that case, it is recommended to install a low bay to provide reasonably acceptable brightness without the intense glare of high bays that may affect workers operating in the lower, more secluded areas.

Lumens, beam angle, and energy efficiency are some of the considerations for spaces with high bay LED lights. The latter will perform better in tasks that will be performed in vertical spaces, minimize shadows, and illuminate the area better. On the other side, low bay fixtures are the way to go for lower ceilings where task-specific lighting is necessary. The best lighting option is any one of them that is properly suited for the layout of the warehouse and required for operations, helping to increase productivity, reduce energy overheads, and enhance workplace safety standards.

Applications of High Bay and Low Bay Lighting

High bay lighting applications are more often located in large indoor environments with high ceilings, such as warehouses, manufacturing facilities, gymnasiums, and airplane hangars. High bay lighting is concentrated and even in lighting large areas, ensuring safety and visibility.

Low bay lighting fixtures are designed for environments with lower ceilings, such as small warehouse areas, retail outlets, workshops, and garages. Low bay lighting focuses light on the place as per the task, which makes it great for environments where fine work or product visibility is needed.

Commercial Lighting Uses

From retail stores to warehouses, tailored lighting solutions have become indispensable for productivity, safety, and ambiance. For instance, LED is mostly used in offices and other commercial buildings, and warehouses have applied this technology more practically as well. When warehouses’ ceilings are greater than 20 feet in height, high bay fixtures are used to provide extra illumination for matters pertaining to production or storage, while low bay lighting proves handy to stay focused and provide exceptional lighting for retail displays or workstations with lower ceilings. Moreover, smart lighting can be afforded by modern commercial establishments to deliver automated control, adaptive brightness levels, and energy savings. The correct type of illumination investment adds visibility and safety, gradually and at the same time decreases operational costs.

Warehouse and Industrial Applications

High bay lighting is a perfect choice for areas with high ceilings and a lot of storage. It ensures that light is distributed correctly over large areas. And, with due attention towards AI, I will recommend control-management systems that can be used alongside the automated lighting system. Smart lighting systems are to be put in place to automate all controls, reducing energy usage so that modern demands are met without cost escalations.

Choosing the Right Bay Lighting for Your Needs

Choosing the right high bay light depends on several factors, including ceiling height, light requirement, energy efficiency, and any special application requirements that may apply. For high bay lighting designed to operate beyond 20 feet, it’s the lumen output and beam angle that you should stress. A high output of lumens will ensure that the whole area is well-illuminated as it goes higher, and different beam angles can accommodate diverse layouts: narrow angles for illumination in specific directions and wide angles for widespread illumination.

In terms of energy efficiency, longer life, and lower maintenance costs, LED high bay light fixtures are the preferred chain while compared with their metal halide or fluorescent counterparts. Additionally, inclusions of dimmable options in smart controls can play into the effort of energy efficiency: the light levels can be adjusted by activities or if daylight is available.

For environments like warehouses, sports grounds, or manufacturing units, check the IP ratings to determine the product structure properly in relation to dust and/or humidity resistance. Particularly for user comfort, the light color temperature is very important – warm tones (3000K-4000K), and the cooler tones (5000K-6000K) should follow the criteria for productivity and visibility problems. If you consider these things, you will be easily able to meet the specifics of each one related to safety, efficiency in operation, and savings.

| Feature | High Bay Lighting | Low Bay Lighting |

|---|---|---|

| Ceiling Height | 20-40 feet or more | 12-20 feet |

| Lumen Output | 15,000-30,000+ lumens | Lower lumen output |

| Beam Angle | 60-90 degrees (narrow) | 120+ degrees (wide) |

| Typical Applications | Warehouses, manufacturing facilities, gymnasiums, airplane hangars | Retail stores, workshops, garages, small warehouses |

| Light Distribution | Focused, concentrated | Even, diffused |

| Design Features | Advanced reflectors and lenses | Simpler design with diffusers |

| Power Capacity | 150-200 watts | Lower wattage |

| Installation | Hooks, chains, pendants | Direct mounting, simpler installation |

Reference Sources

Frequently Asked Questions (FAQs)

What is the difference between bay and low bay lights for high and low bay lighting?

Main difference in relation to bay vs low bay light is the mount heights, ceiling height, and distribution of light; if referring in general rather than the scale and installation distribution. High bays are meant for higher ceilings, that is, 20-45 feet, which dispense a strong, even illumination to keep the high ceilings finely lighted and reduce frequent glare, while low bays are deemed appropriate in the area’s lower ceilings, roughly around 12-20 feet, and ensure the right level of light illumination without excessive glare. High bay warehouse lighting and low bay lights are produced using different optics and lumen outputs; so while comparing high bay vs low bay light, it will depend on the height of the space, task requirements, whether you need standard bay and low bay fixtures, or a single-way solution.

How does an LED low bay light compare to fluorescent light for residential and commercial energy and lighting needs?

In terms of efficiency, lifespan, and maintenance, LED low bays provide better performance as compared to fluorescent fixtures in many provisions for commercial and residential building lighting. LED low bay fixtures are instant on, provide greater color rendering, and consume less energy, all making them the preferred choice for a project requiring good lighting and low energy cost. LED lights and bay LED lights are a large quantity source of long-term value and betterment of LED’s lighting products (retrofit or new electrical and lighting work) for their lighting generation requirements for residential or mixed commercial/residential. When making a long-term benefit from retrofit kits or any new lighting project, LED lights offer the best solutions.

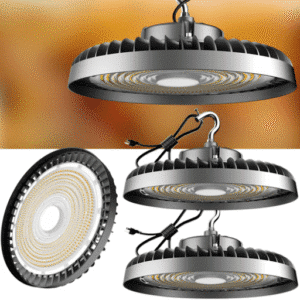

When to choose UFO high bay or LED high bay lights for my warehouse?

Choose UFO High Bays or LED UFO High Bays when you need compact, high-output bay lights that can be used in high bay warehouse lighting, anywhere ceiling height ranges from 20-45 feet. UFO LED high bay fixtures are in great demand as they deliver a large output in a very small package and are very easy to mount or suspend. SPI spread the lighting brilliantly in the open areas and reduced the fluorescent natural light of high-intensity building workspaces. Bay LED lights are energy-efficient and are frequently preferred for re-equipping outdated fluorescent bulbs.

In the case of low bay mounting (say 12-20 feet), why?

Mounting and installation will mostly depend on the height for either case. Low bay lights will be either flush-mounted or installed suspended in places ranging between 12 and 20 feet, whereas high bay lighting is utilized for any space height that is between 20 and 45 feet high; it is commonplace for an installation to employ some kind of pendant, hanging chain, or demanding installation, but unlike low bay lights. Any bay light may go together with a hook, pendant, or bracketing; make the best choice from any High Bay or Low Bay fixtures established or built in lighting forms such as Linear High Bays, Linear Low Bays, UFO LED High Bays, and some traditional fluorescent lights, according to your electrical and lighting needs, and for easy installation practices.

Are bay lights capable of creating indoor lighting installations?

Yes, bay lights can be used on an assortment of commercial and residential projects if properly paired: low bays are capable for home elbows, workshops, and basements, whereas high bay and UFO high fixtures are for warehouse, gymnasium, and commercial-sized spaces. Bay lighting may be tailored to fulfill the lighting needs of residential electrical project components through lower lumen output and essentially good shielding crafted enough for optimal lighting without glare. The best lighting manufacturers have models meant for mixed-use and retrofit consideration.

How can linear high bays, linear highs, and UFO LED high bays give equal distribution of light?

Depending on the design and the aim of light dispersion, the linear LED high-bay light creates a more consistent light rowed effect and can fit well with aisles and racking in the warehouse, while an ultra-bright, less common downlight delivers a higher lumens-to-watt ratio, which is very suitable for open areas. Design your high bay with the application to embrace the majority of light, be it linear high bay, favoring spotted light-it is interested in racking with no glare, whereas a huge space with high ceilings would be best covered by UFO high designs. This is also a lighting level, glare control, and the length of the bay lights to be suspended for optimal spread of light and minimal glare.

What are the specifications and best lighting manufacturers to look out for when I want to purchase bay LED lights?

Please check on a reliable manufacturer who has clear specifications in lumen output, Efficacy (lm/w), color temperature, CRI, warranty, and IP rating. The most important lighting manufacturers give Michael variety in high bay LEDs, such as LED UFO high bays and linear high bays, and provide scrutinyable information to compare the benefits and drawbacks of some higher and lower bay light solutions. Although some lights are indeed mounted, whether the lights come with mounting solutions to such lights or whether they will cater to dimmable option capability, plus thermal management. Quality products will allow compatibility stemming from shaping and to consider electrical as well as lighting project requirements for the best long-term performance.