The points below pinpoint troubles with high ceilings and their adequate lighting ways. They are part of the decision-making process for the appropriate lighting and are not solely an aesthetic concern but really important to the(space) overall function, safety, and power usage. High bay lights are efficient for all the industrialm, commercial and large indoor areas that have ceiling heights of more than 20 feet and they reach the peak of 30-foot ceilings as well. Yet, to find the best high bay lights out of the many options available in the market is quite a challenge. This guide is going to be your best friend on the journey of finding the perfect high bays lighting for 30-foot ceilings. If you’re upgrading a warehouse, gym, or retail space we will talk about the key features, technologies, and advantages that make these lighting systems just right for your needs.

Understanding High Bay Lights

What is a High Bay Light?

High bay lamps are the type of lights that are intended for high ceilings (usually 20 feet or more) and are adaptive in many applications. They are mainly used in industrial areas, warehouses, and so on, places where big areas need to be illuminated with powerful and uniform light. The high-tech models such as LED and HID convert power into light way more efficiently and last a long time, thus being more cost-effective than the traditional lighting options. The low amount of glare along with the good distribution of light also play a big part in making them very user-friendly in terms of visibility and safety.

The Importance of Lighting Design for High Ceilings

In lighting design for high ceilings, one should not ignore lumen output, beam angles and energy efficiency which are the main factors ensuring the best possible light quality. High ceilings require lighting systems that can create enough light for both vertical and horizontal spaces with the same shadow-free and uniform light spread quality. Choosing luminaires with adjustable beam angles allows designing light coverage according to exact requirements while energy-efficient methods such as LEDs will reduce operational costs. Furthermore, positioning and spacing of fixtures correctly have been crucial for obtaining uniform light distribution that in turn increases safety and supports the productivity of large areas.

Various Types of High Bay Lights

High bay lights can be found in various types, each for specific applications and environments:

LED High Bay Lights: In terms of energy consumption and lifespan, they are the best choice, meaning that maintenance costs will also be lower.

Metal Halide Lights: Produce extremely bright and very white light, but this comes with high electricity usage and heat generation.

Fluorescent High Bay Lights: The lowest in cost among energy-efficient light sources, thus making it the best choice financially at the beginning, despite the fact that they need regular replacements because of their short-lived nature.

Induction High Bay Lights: They are long-lasting with good efficiency but their uptake is slow because they are expensive and not so easy to apply.

The right type of light depends on criteria like energy efficiency, usage area, maintenance required, as well as the budget available.

Types of High Bay Lights

Linear High Bay Lights

Linear high bay fixtures are among the most popular ones utilized in places such as big warehouses and factories that need bright and even light spread over wide areas. They are the most energy-efficient and their light output is the same all over the place, thus there are no shadows left even in the corners of the working area that are not being used frequently. Usually, the lights consist of LED technology, which not only gives the long lifespan but also very much lower energy consumption and maintenance costs. Their application is widespread in low and high ceiling areas and the size of the linear high bay lights is such that they can be employed in different layouts with various types of lighting. They have a reasonably high initial cost, but their broad functionality makes them a perfect fit for many sectors.

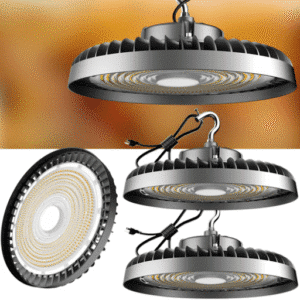

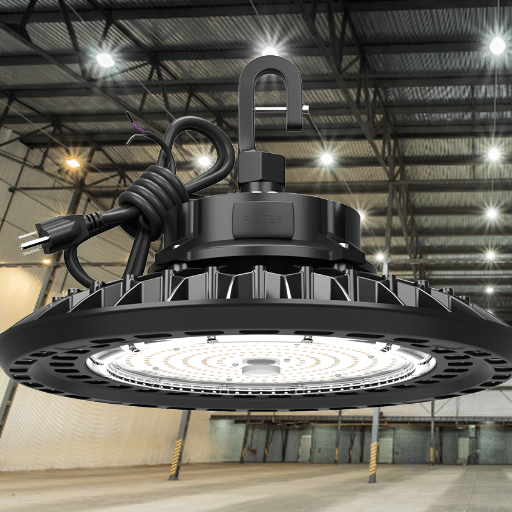

UFO High Bay Lights

UFO high bay lights are so called because of their modern round and disc-like shape that resembles a UFO, and they are designed for high-ceilinged areas in factories and warehouses about 15 to 35 feet high. These units are based on advanced LED technology providing very high lumen output in a wide beam angle, which makes the illumination of large areas quite superior.

Key Features Buyers Consider:

- Energy efficiency

- Ability to withstand tough conditions

- Easy installation

The lights consist of highly durable materials, and aluminum heat sinks are usually incorporated in their structure for the purpose of cooling, hence, increasing the lifespan and performance of the lights in harsh conditions during usage in warehouses, factories, and gymnasiums. In addition to that, the lights have an IP65 rating or more, which indicates that they are a total dust-tight and resistant to water jets from any direction, leaving the option of use for them indoors or in semi-outdoor settings opened.

Besides, the smart control systems such as dimmable and motion-sensor-controlled lighting integration have attracted the users who are in quest of efficient lighting solutions, and these systems are getting more attention than ever before. Their energy-saving aspect is accompanied with the ability to provide lighting changes that are most suitable to the actual operational requirements.

Linear and UFO High Bay Lights: A Comparison

| Feature | Linear High Bay | UFO High Bay |

|---|---|---|

| Design | Elongated shape | Compact round design |

| Best For | Wide aisles or rectangular spaces | Open-area factories or gymnasiums |

| Light Distribution | Even, linear light coverage | Wide, symmetrical distribution |

| Intensity | Moderate to high | High intensity output |

| Durability | Standard durability | Superior with better heat dissipation |

| Ideal Application | Warehouses, retail spaces | Factories, gymnasiums, high ceilings |

The overall selection between the two options will come down to the unique characteristics of the layout, ceiling height, and lighting requirements of that particular space.

Choosing the Right High Bay Light for 30-Foot Ceilings

Factors to Consider in Lighting Layout

In the case of lighting layout for 30-foot ceilings, there are several important factors to consider to achieve maximum performance and efficiency:

✓ Key Considerations Checklist:

Lumen Output: It should be in accordance with the lighting requirements of the area. Generally, more lumens are needed for intricate jobs or when vast areas require lighting.

Beam Angle: It plays a role in determining how light is distributed over the area. Less light is directed in a focused manner with narrow angles, while wide angles can cater for the largest areas easily.

Ceiling Height: It affects the spacing between light fixtures, which must be done in such a way that there are neither overlapped nor dark zones.

Color Temperature: It should correspond to the environment. Cooler tones are the best for the workplace, whereas warmer tones are suitable for the lounges.

Energy Efficiency & Maintenance: They are the two main points that determine the operating costs and performance in the long run.

Warehouse Lighting Requirements

To meet warehouse lighting requirements, the most important element is the uniformity of light distribution—ensuring no dark spots or shadowy areas, resulting in maximum visibility for safety and productivity purposes.

Best Practices for Warehouse Lighting:

Fixtures must be placed so that the distance between them equals the height of the ceiling, ensuring that there is light overlap and that there are no very bright spots

To improve workers’ productivity, select cool white color temperature (4000K-5000K); do not use very warm tones

Choose LED lighting with high energy efficiency for the lowest operational costs and also very little maintenance since they are lasting and giving excellent performance in comparison with conventional lighting solutions.

Types of LED High Bay Lights Suitable for High Ceilings

Different types of LED high bay lights are perfect for high ceilings, and each type has its own specific application:

UFO High Bay Lights

Small and powerful with wide and uniform light distribution. Ideal for warehouses and gymnasiums with all-open areas.

Linear High Bay Lights

Provide long coverage for aisles, retail spaces, and workshops requiring directional lighting.

Reflector-Style High Bay Lights

Draw attention downwards, mostly used with aluminum or prismatic reflectors in places of concentrated illumination demand.

The lights are tailored for high ceiling installations, which will ensure optimal performance if selected according to the lighting requirements of the environment.

Benefits of LED High Bay Lights

Energy Efficiency of LED High Bays

Due to their modern technology, which consumes very little power as compared to the old systems like metal halides or fluorescent fixtures, LED high bay light fixtures are tops among the super energy-conscious lighting devices. Their power to light conversion is more effective since they generate nearly no heat, thereby reducing the loss of power through electricity wastage to the barest minimum. The energy-efficient accompanied with lower bills makes them a green and cost-effective lighting solution for both industrial and commercial areas. Moreover, their very long lifespan means fewer replacements in which case maintenance cost and time will also be minimized alongside the operational efficiency increase.

Longevity and Maintenance of LED Light Fixtures

LED light fixtures are famous for their great longevity, often exceeding 50,000 hours under normal operating conditions. This lifespan is due to the solid-state design that has no fragile filaments or glass parts as in traditional lighting.

Key Advantages:

Preserve luminosity for long times with nearly zero deterioration

Deliver uniform output during their entire period of use

Very long life drastically reduces the number of substitutions, thus cutting labor and costs

Robust construction makes them more resistant to damages caused by vibrations or external blows

Routine cleaning and infrequent inspection for proper functioning are typically the only maintenance needs

Cost-Effectiveness in Commercial and Industrial Settings

The LED high bay lamps yield the greatest savings in total cost of ownership in manufacturing and commercial facilities mainly because of their life time, energy efficiency, and nearly no maintenance at all. The long life of the units means that the replacement costs are lower and less frequent, and the energy efficiency gradually reduces the operating expenses positively. Besides, only routine cleaning and inspections are needed, which also reduce maintenance labor and costs. All these reasons are the key to the huge decline in the total cost of ownership, thus making them an economically acceptable option for big operations.

Installation and Fixture Options

Best Practices for Installing High Bay Fixtures

The first step in the installation process of high bay fixtures is proper assessment of the space’s particular requirements:

Installation Guide:

Space Assessment: Measure ceiling height, take a look at the layout and figure out the use of the space in order to make the right decision about the position and the number of fixtures

Electrical Connections: Check the circuits for compatibility and conformity with the wiring codes and standards that apply

Mounting Hardware: Mount fixtures securely with the right equipment for their weight and design like chains, hooks or brackets

Fixture Spacing: Put up the lamps with enough separating distance to get the lighting to be evenly distributed and also to reduce the shadows

Energy Management: If energy management features are required, make sure that all the lights are dimmable

Post-Installation: Do thorough inspections to verify that the conditions are met for stability, operability and compliance with safety standards

The Decision Between Low Bay and High Bay Options

The main divergence between low bay and high bay lighting options is their application and mounting height requirements:

| Aspect | Low Bay Lights | High Bay Lights |

|---|---|---|

| Ceiling Height | Up to 20 feet | Over 20 feet |

| Typical Applications | Retail stores, workshops, garages | Warehouses, factories, gymnasiums |

| Light Distribution | Concentrated and uniform at lower heights | Strong beam covering wide vertical and horizontal spaces |

| Key Considerations | Building height, moderate light intensity | High intensity, lumen output, beam angle |

The selected option must be able to cater to the environment’s specific requirements in terms of lumen output, beam angle, and energy consumption while still complying with safety and performance standards.

Lighting Design Adjustment for Optimal Performance

The lighting design adaptation for achieving the best performance begins with an assessment of the ceiling height to decide on the fixture type—low bay for ceilings under 20 feet and high bay for taller ceilings. The lumen output requirement has to be determined based on the dimensions and use of the room, permitting light to be luminous enough but at the same time not causing glare or consuming too much power. Opt for lights with the correct beam angle so that there are no dark spots and poor lighting in the area where the light is well distributed. The most energy-efficient alternatives, such as LED lights, should be given priority in order to reduce long-term operational costs and at the same time maintain compliance with workplace safety and industry standards.

Frequently Asked Questions

Can I use LED round fixtures for ideal lighting in high bay environments at 30 feet?

Absolutely, with the appropriate round optic and lumen package selected based on the space requirements, LED round fixtures can serve as a perfect lighting source in a variety of high bay applications at 30 feet. In most applications, round high bays deliver broad and even distributions that are perfect for open spaces and wide aisles. Determine the fixture’s beam angle and intensity in such a way that you will meet the illuminance targets without resorting to high fixture density. For concentrated tasks or narrow aisles, opt for linear or asymmetric optics instead of round ones. Height of the light, find high bay and professional lighting are the suggested terms not to be used.

How to use LED for lighting in a warehouse with a ceiling height of 30 feet?

When it comes to a high bay with a ceiling of 30 feet, the installation of LED fixtures will produce more lumen plus energy efficiency than the traditional HID lamps, taking into account that the lumens produced and power consumed are high with the LED lamps. High ceiling fixtures and wide beam distributions should be chosen together to guarantee the right lighting level at the floor. The mounting height is the most important factor in lumen output selection — high bay LEDs that are rated for 25–35 feet will be perfect for 30 feet. If the space matches color rendering, it will be better to select fixtures with higher CRI.

When should you use LED to meet the lighting needs for a 30-foot high workspace?

In a workspace with 30-foot ceilings, you should opt for LED lights if you want lower maintenance, high efficacy, and instant on/off performance. LED usage results in lesser re-lamping, gives off more lumens per watt, and is thus more useful in high bay hard-to-reach areas. Determine the amount of foot-candles needed for the specific task areas and select lumens for fixtures accordingly. Dimming and controls can further optimize energy use and prolong the life of the fixture. Suggested unused terms: number of lights you need, professional lighting, find high bay.

Why use LED when selecting high bay LED options for a 30-foot ceiling?

Opt for LED because the leading high bay LED brands have a variety of their characteristics such as suitable for 30-foot ceilings, light distribution, wattages, and mounting accessories. Seek for models with reliable thermal management and guarantee coverage for commercial installation as well. At this height, beam pattern choice (narrow, medium, wide) is of paramount importance to avoid hot spots or dark aisles. Also, compare the lumen output and spacing guidance provided by the manufacturers to estimate the number of fixtures required. Suggested unused terms: best lighting, large selection of high, ideal lighting.

How can facilities determine the number of lights needed for a 30-foot ceiling high bay?

For calculating lighting fixtures in a high ceiling of 30 feet, the LED lighting should be used effectively by first settling on the intended illuminance (foot-candles) and measuring the area dimensions. You can utilize lighting calculators or photometric files from the manufacturers to simulate the impact of spacing, aiming, and mounting height on delivered lux. Calculate the light loss factors like dirt buildup and maintenance intervals while sizing the system. To ensure even distribution and compliance at task level, either conduct a mock-up or photometric simulation to support your layout. Suggested unused terms: high bay lights are commonly, perfect lighting, led warehouse lighting.